Automatic loading and unloading brick transport cart of truck-mounted crane

An automatic loading and unloading and truck-mounted crane technology, which is applied to vehicles with cranes, cranes, etc., can solve the problems of inability to complete loading and unloading, large space occupied by boom rotation, and difficult loading and unloading, and achieve continuous loading and unloading, and the occupation of boom rotation Reduced space and improved loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

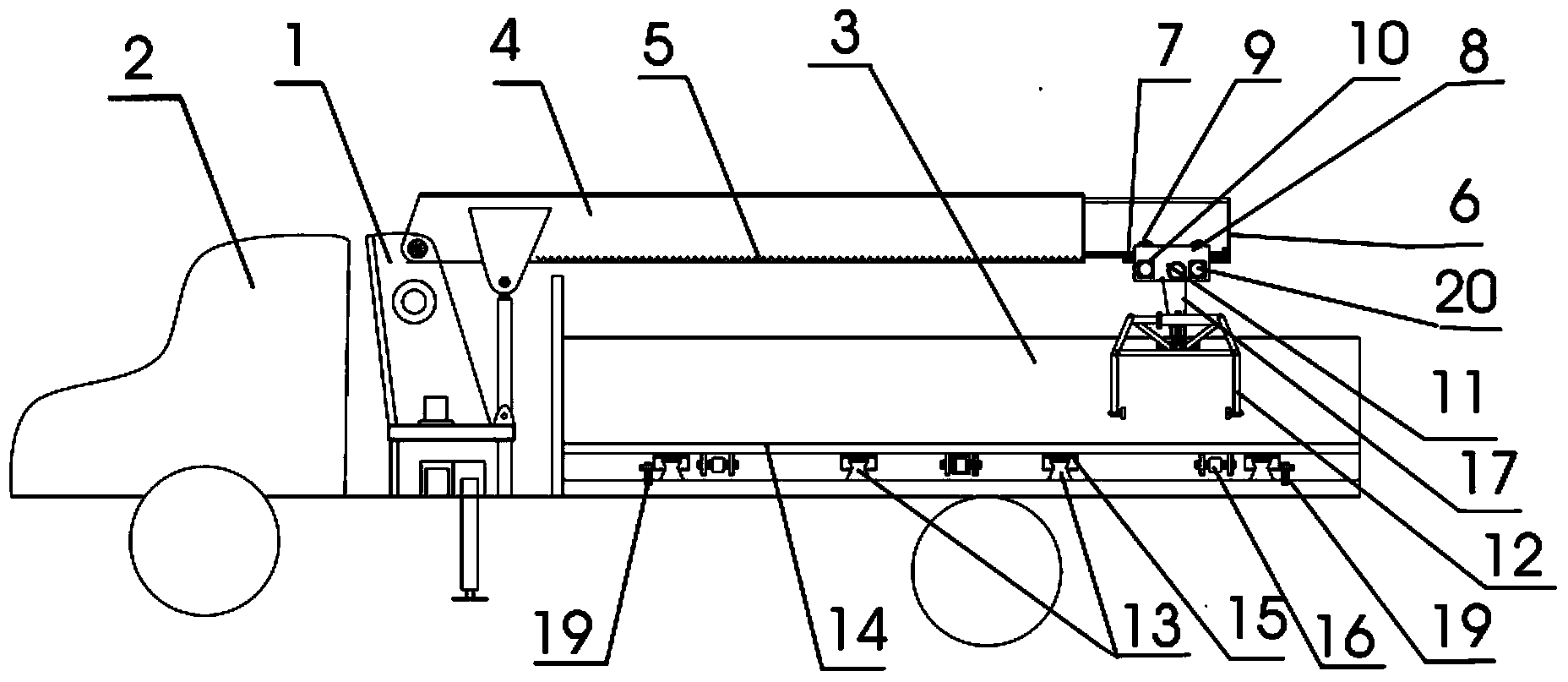

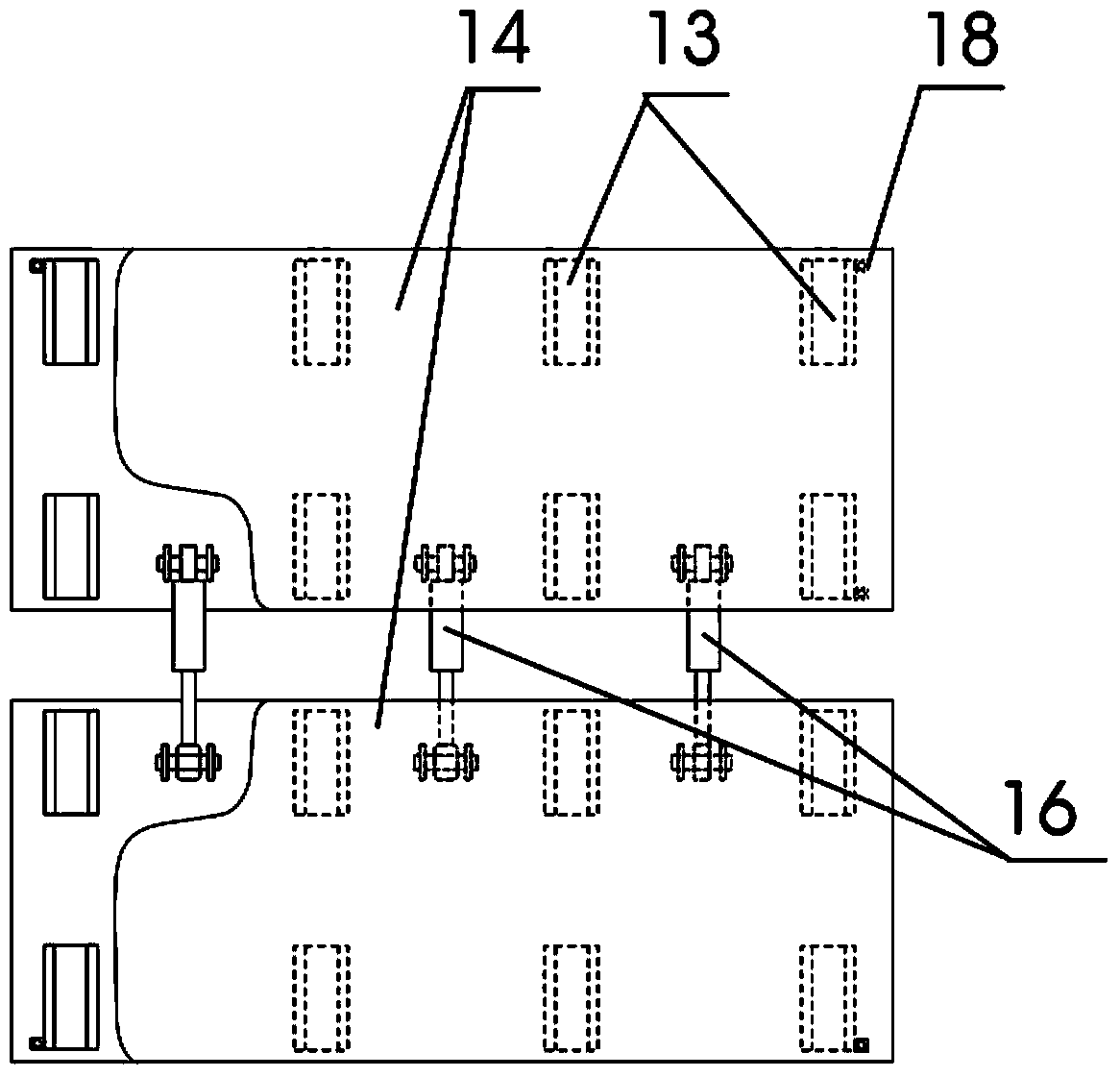

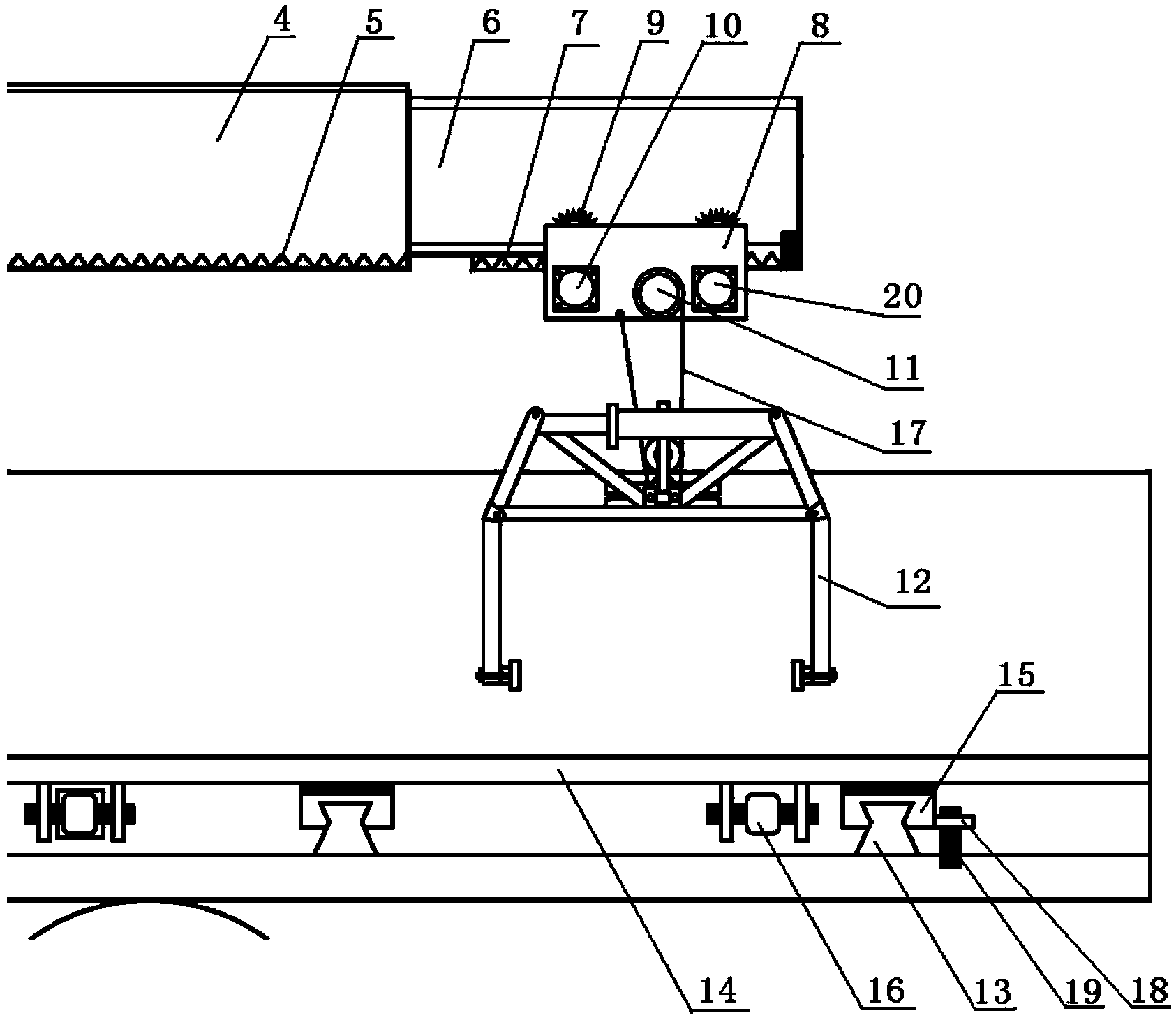

[0013] Attached below figure 1 , 2 , 3 describe an embodiment of the present invention.

[0014] A truck-mounted crane for automatically loading and unloading bricks, including a truck-mounted crane 1, and the truck-mounted crane 1 is located between the driver's cab 2 and the compartment 3, and the two sides of the lower end of the main arm 4 of the truck-mounted crane 1 have tooth surfaces facing upwards. The main arm 4 is equipped with a retractable boom 6, and the two sides of the top and lower end of the boom 6 have tooth racks II7 facing upwards, and the two teeth of the boom 6 are retracted. The bar II7 is docked with two racks I5, and the crane 8 is installed on the two racks II7 through two pairs of gears 9 and driven by the hydraulic travel motor 10 to move along the two racks II7. The crane 8 is equipped with a lift Winch 11, and the lifting winch 11 is driven by the hydraulic lifting motor 20, the lower part of the lifting winch 11 is suspended with a brick clip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com