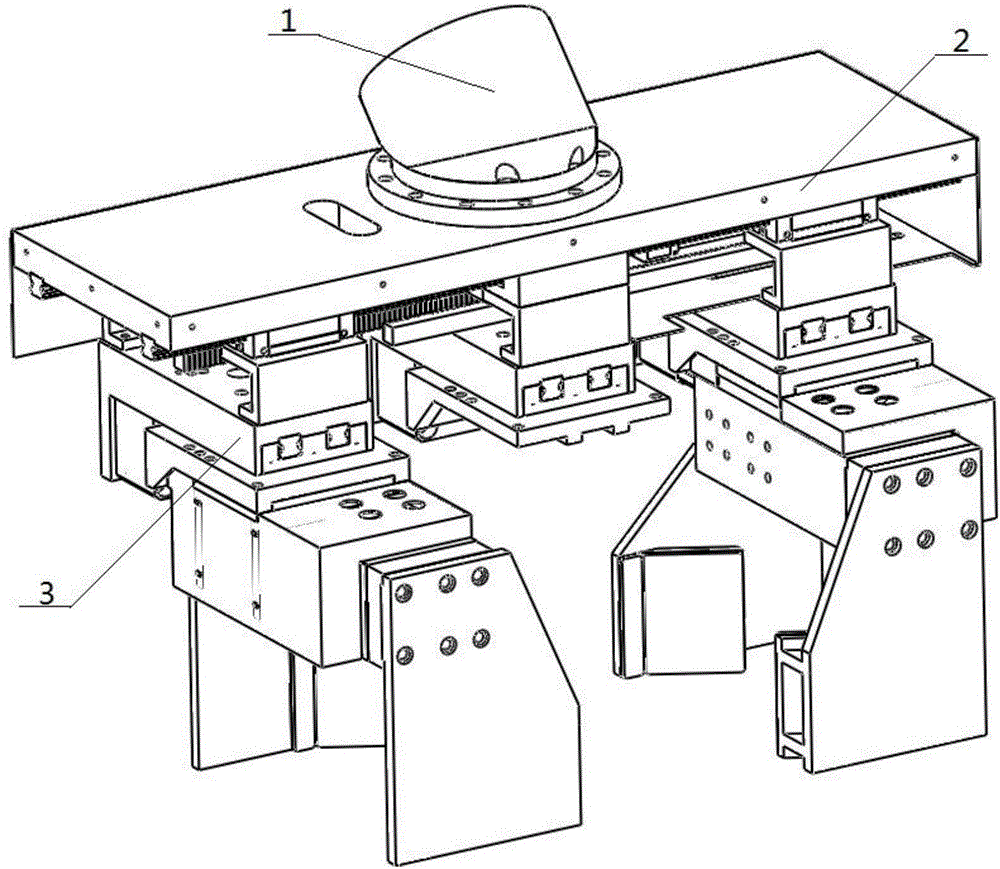

Multifunctional robot gripper for piling of special-shaped bricks

A robot hand and multi-functional technology, which is applied in the direction of manipulator, object stacking, object destacking, etc., can solve the problems of complex stacking and difficult clamping of special-shaped bricks, and achieve convenient switching, improve production efficiency, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

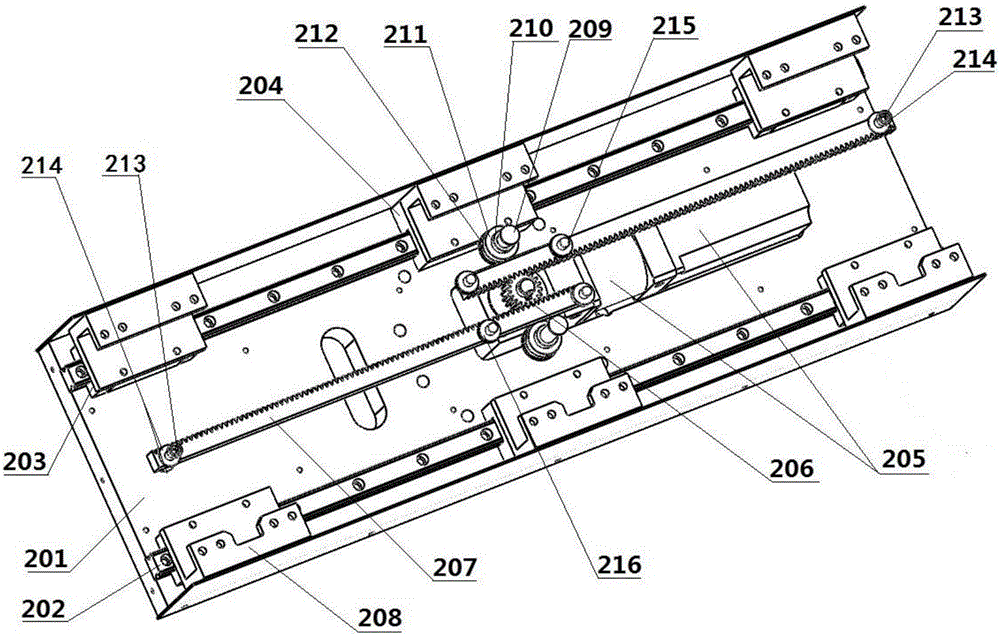

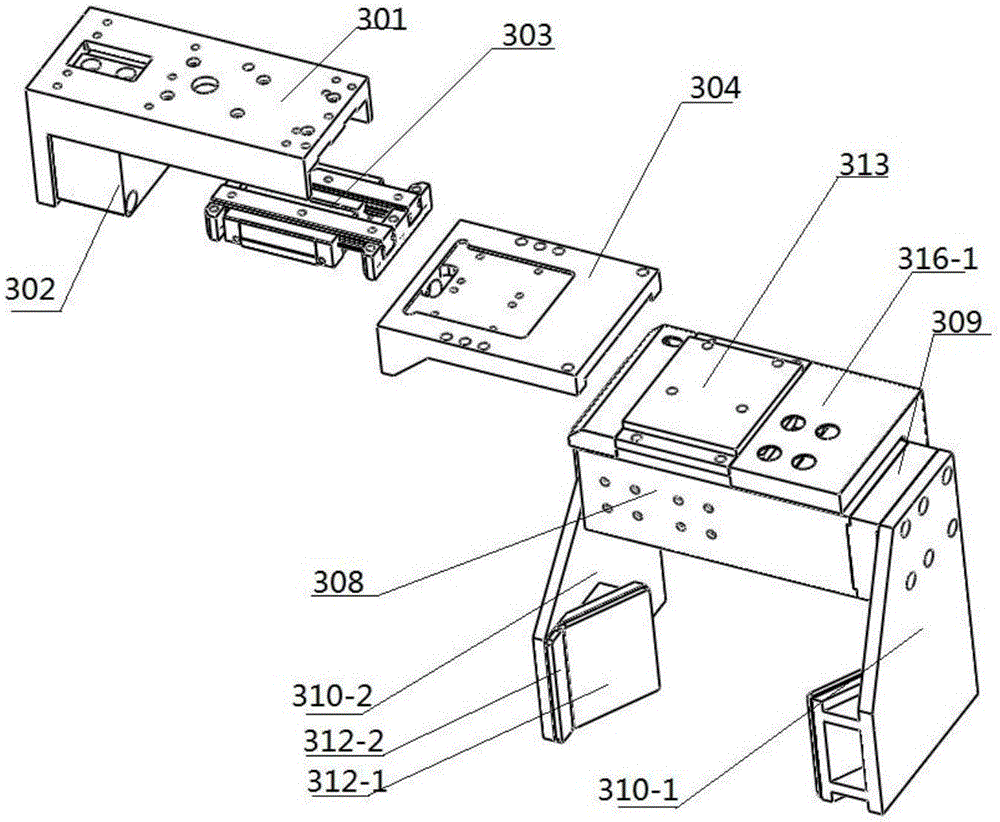

[0016] As an embodiment of the present invention, the shape of the inner wall of the two plywood adopts the structures 312-1 and 312-2 that can clamp the special-shaped brick 4-A with quadrilateral end face, and the outer plywood 310-1 and the inner plywood 310-2 The inner surfaces of the outer splints 310-1 and the inner splints 310-2 are welded with wedge angles that fit the end faces of the bricks; The structures 317-1 and 317-2 of the brick type 4-B with both ends parallel, the inner surfaces of the structure 317-1 and the inner splint 317-2 are planes that fit the end faces of the bricks, because the two splints clamp the brick The two left and right end faces, the clamping direction is perpendicular to the length direction of the base body, so driven by the rotating motor reducer assembly 205 in the base body, the finger assemblies on the front and rear sides can move inward, that is, the inner sides of the two bricks are close to each other, and they can be lifted and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com