Wall building machine

A wall-laying machine and hose technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of low labor efficiency, uneven quality, and high labor costs, reduce labor costs, and speed up project progress. , the effect of improving the quality of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

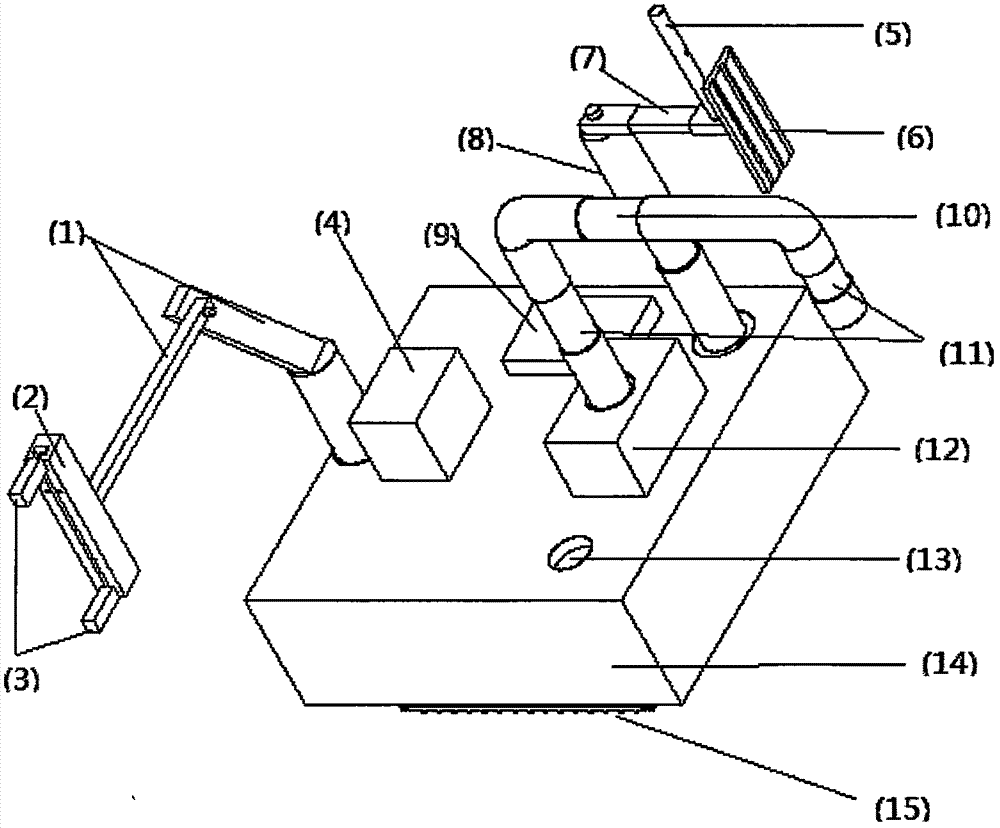

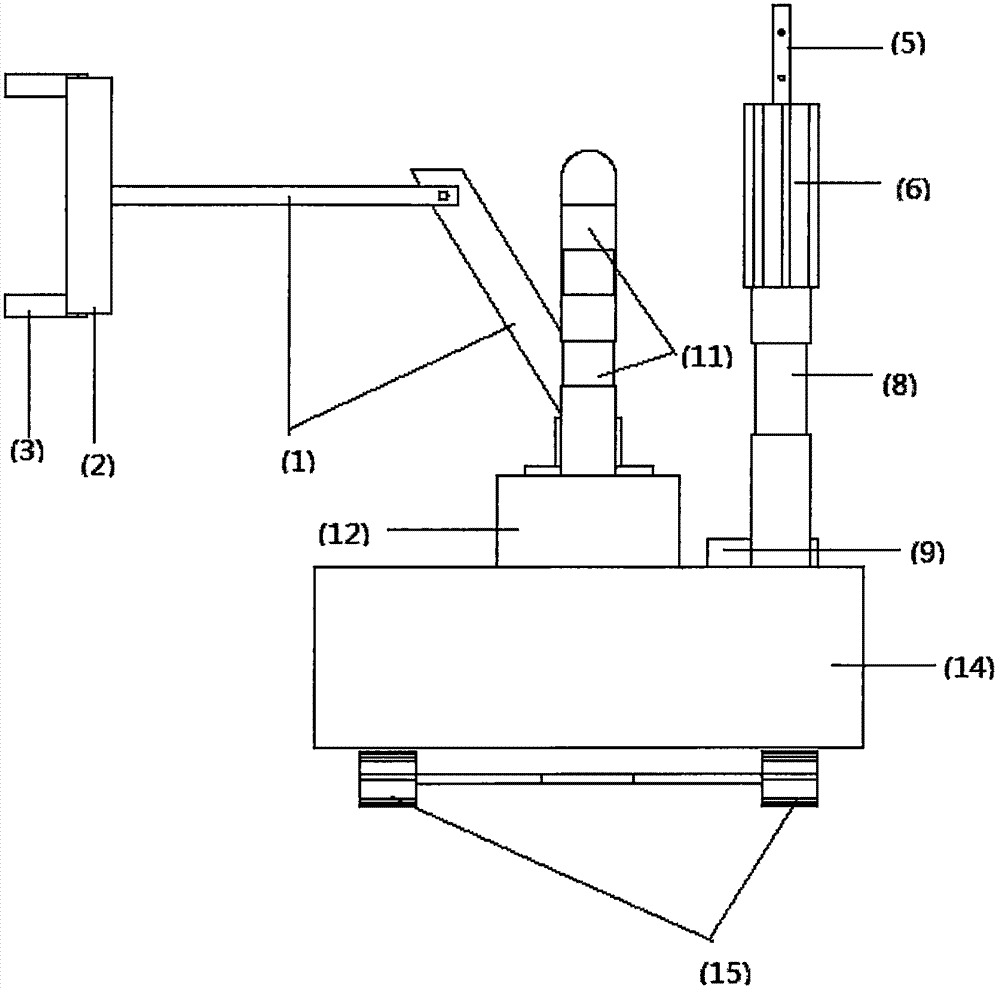

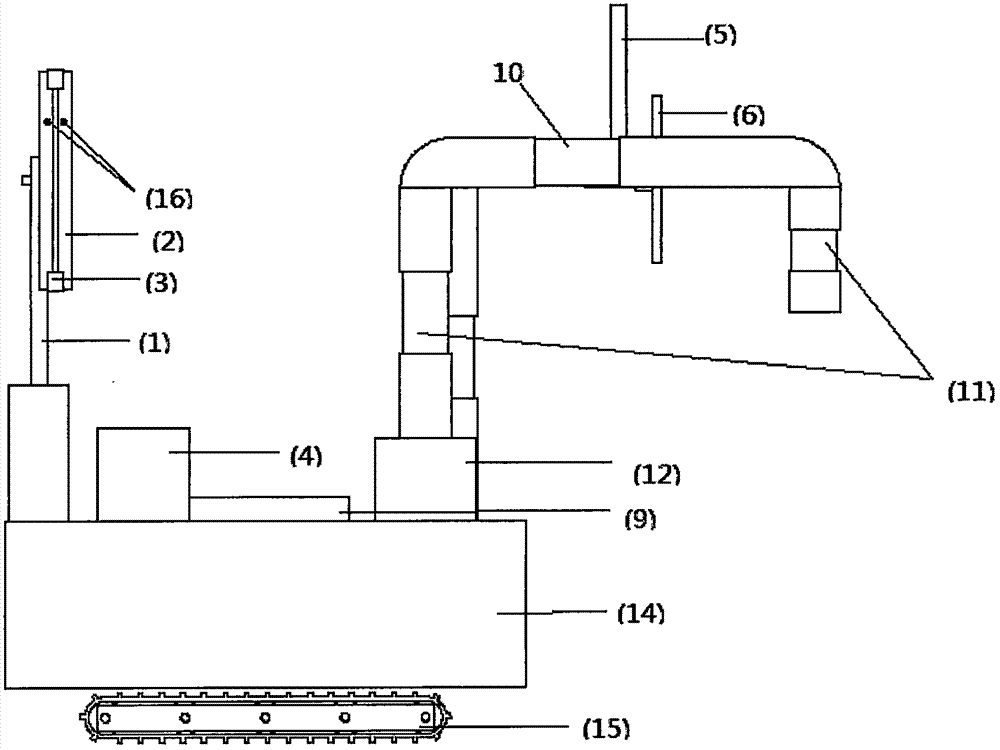

[0015] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 It can be seen that the present invention consists of a mechanical arm (1), a sliding clamping groove (2), a brick clamp (3), a brick clamping motor (4), a leveling positioning device (5), a leveling plate (6), and a leveling adjustment device ( 7), smoothing vertical adjustment device (8), control system (9), hose horizontal adjustment device (10), hose vertical adjustment device (11), smoothing cement motor (12), cement injection port (13) , a box platform (14), a moving system (15), a brick clamp positioning device (16) and a hose positioning device (17).

[0016] The specific working process of the wall-laying machine is as follows:

[0017] 1. Move the entire wall-laying machine to the position where the wall needs to be built by the mobile device (15), and set the brick type, cement injection amount and smoothing thickness through the control system (9).

[0018] 2. Place the scattere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com