Automatic post-brick-unloading grouping and loading device and technology for baked bricks

A technology of brick unloading and sintering bricks, which is applied in the field of automatic assembly and assembly equipment after sintering bricks unloading, which can solve the problems of low utilization rate of the carriage, increased damage rate of finished bricks, transfer costs, and large gaps, etc., to improve the full load Rate and vehicle utilization, save manpower, reduce the effect of damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below in combination with specific embodiments.

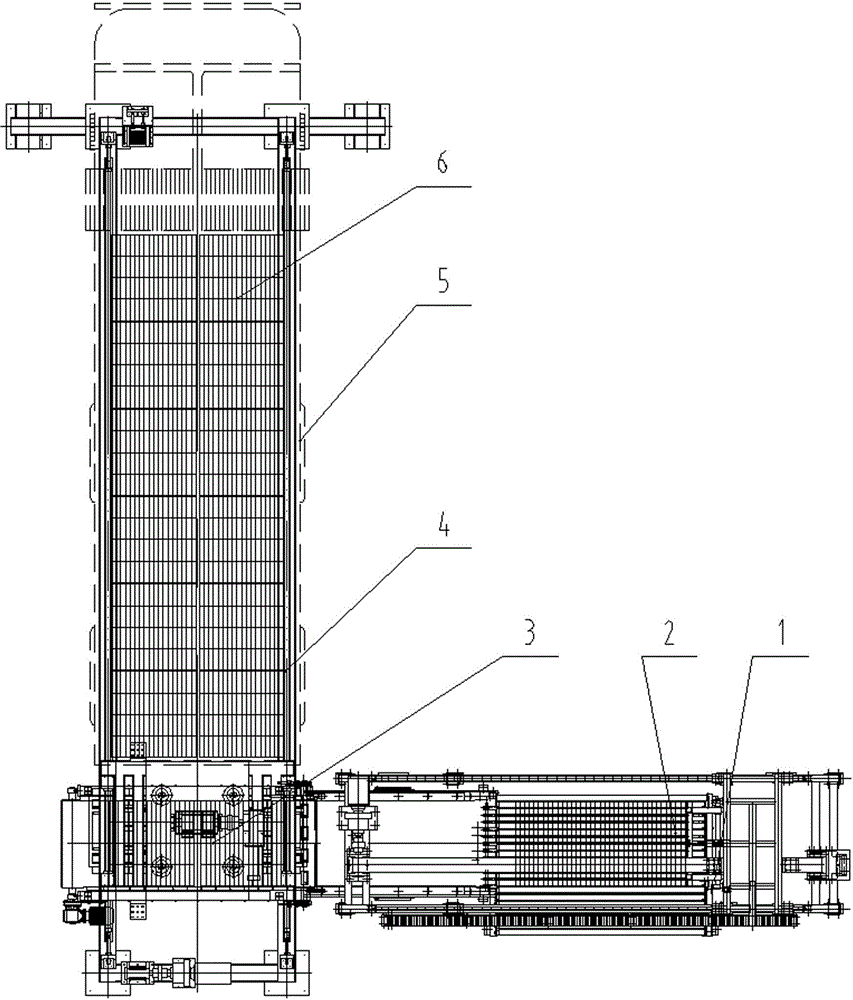

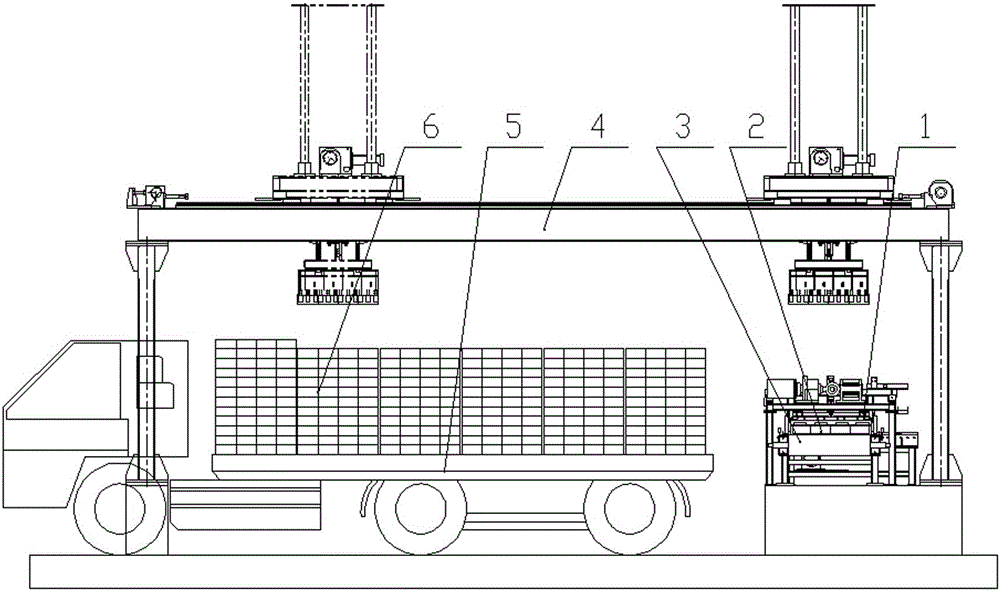

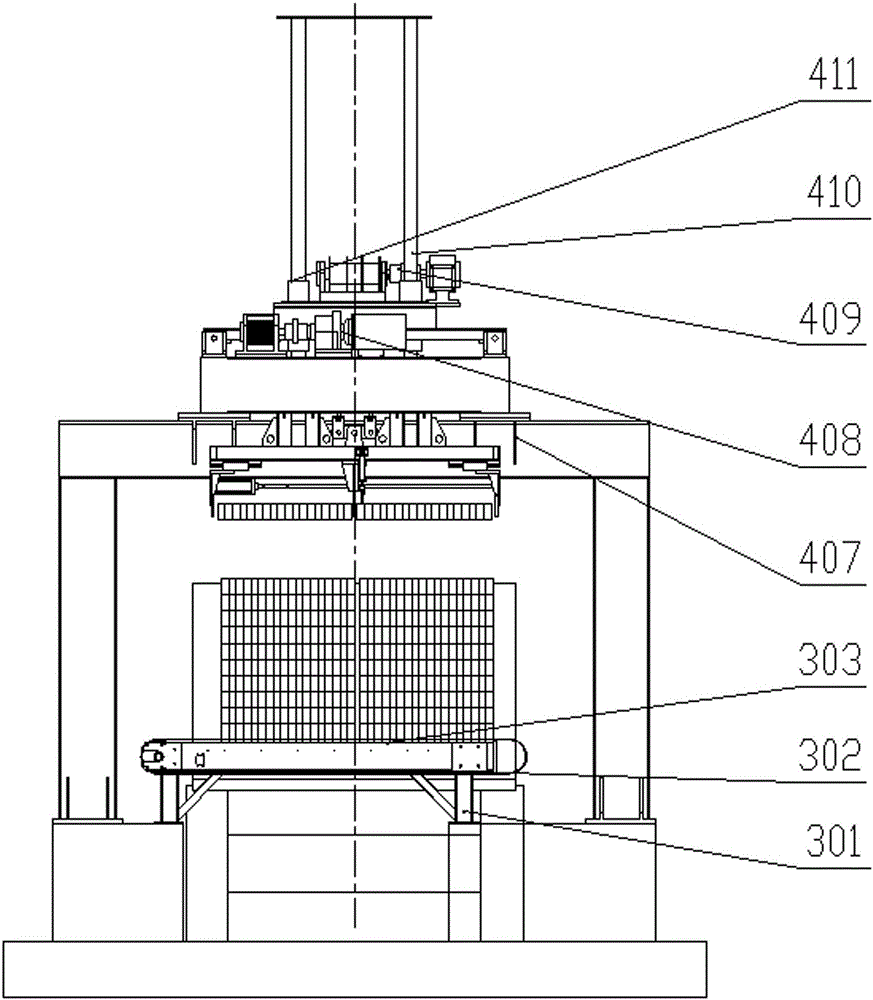

[0026] An automatic marshalling and assembling device for sintered bricks after unloading, the device is provided with a marshalling belt conveyor 3 for grouping sintered bricks 2 after unloading, and a coder for clamping and loading sintered bricks 2 after grouping The stacker 4 and the transfer mechanism 1 of the brick unloading unit, the marshalling belt conveyor 3 is arranged at the end of the brick unloading unit transfer mechanism 1, the brick unloading unit transfer mechanism 1 gathers the sintered bricks 2 and marshals them to the marshalling belt conveyor 3, and the marshalling belt The machine 3 cooperates with the transfer mechanism 1 of the brick unloading unit to group the sintered bricks 2 according to the width of the transport vehicle 5, and the palletizer 4 is set above the grouping belt conveyor 3, and the palletizer 4 clamps the grouped sintered bricks 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com