Automatic steel pipe chamfering machine

A chamfering machine, fully automatic technology, applied in the field of steel pipe manufacturing, can solve the problems that the processing capacity of the chamfering machine cannot meet the requirements simultaneously, the structure and power of the chamfering machine need to be improved, and the cutting capacity of the chamfering machine is insufficient, etc., to achieve collection The method is convenient and reasonable, the effect of eliminating unsafe factors and perfect safety protection measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described below in conjunction with the drawings.

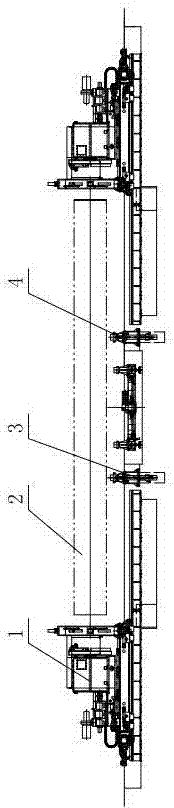

[0032] Such as figure 1 As shown, in the full-automatic steel pipe chamfering machine of this embodiment, in the actual application process, the steel pipe 2 is supported by the pipe carrier 4, and at the same time, the height position of the steel pipe 2 is adjusted by the support cylinder 3 inside the pipe carrier 4. The mobile cutting switchboard 1 is installed at each end.

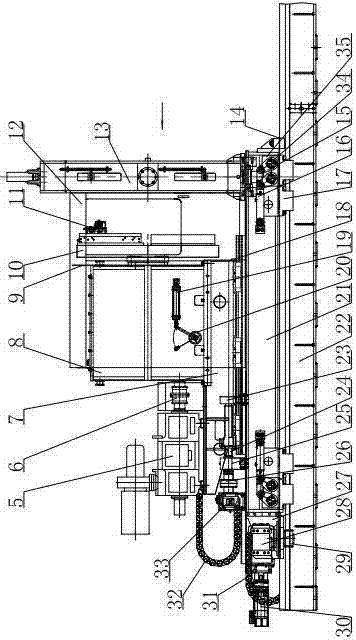

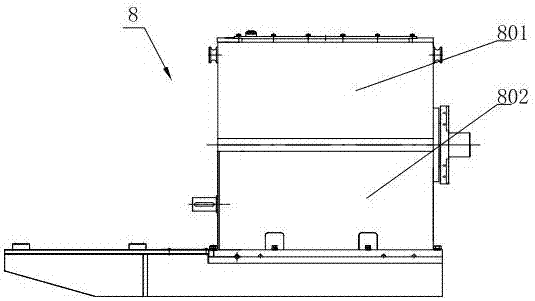

[0033] Such as figure 2 with image 3 As shown, the structure of the mobile cutting switchboard 1 is as follows: includes a base 22 on which a large carriage 21 is installed. Both ends of the large carriage 21 are respectively equipped with hook plates 17, which are driven by the hydraulic cylinder drive device. 22 Hook tightly; a base box 7 is installed on the large carriage 21 through a slide rail, and a bedside box 8 is installed on the base box 7 through fasteners. The bedside box 8 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com