Dynamic wood chip sampling machine

A sampling machine, a dynamic technology, applied in the field of papermaking, can solve the problems that cannot meet the needs of the development of raw material logistics and management requirements, trouble the procurement of wood chips for pulping production, and high labor intensity, etc., to achieve simple and practical structure, scientific sampling method, and collection The effect of method science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

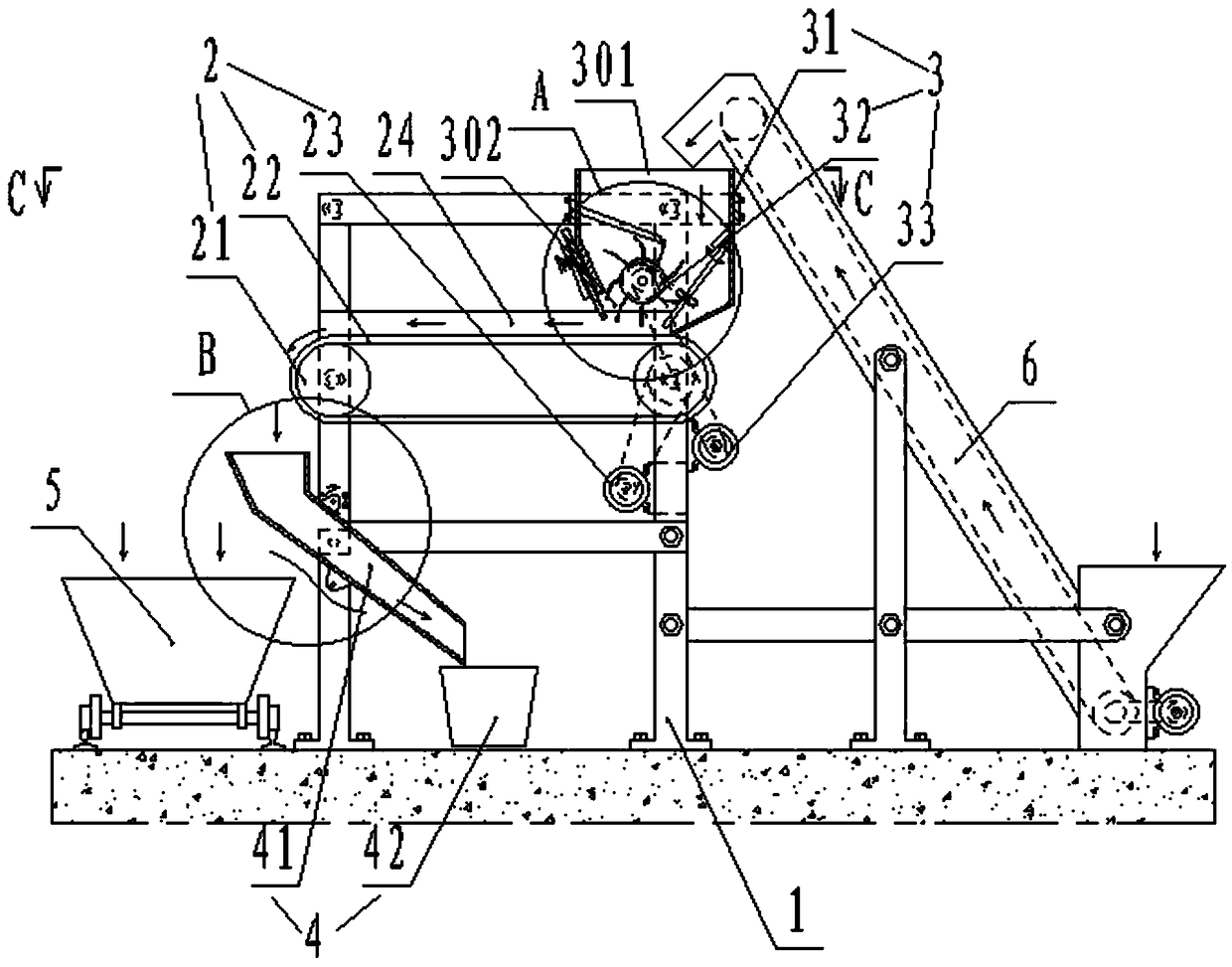

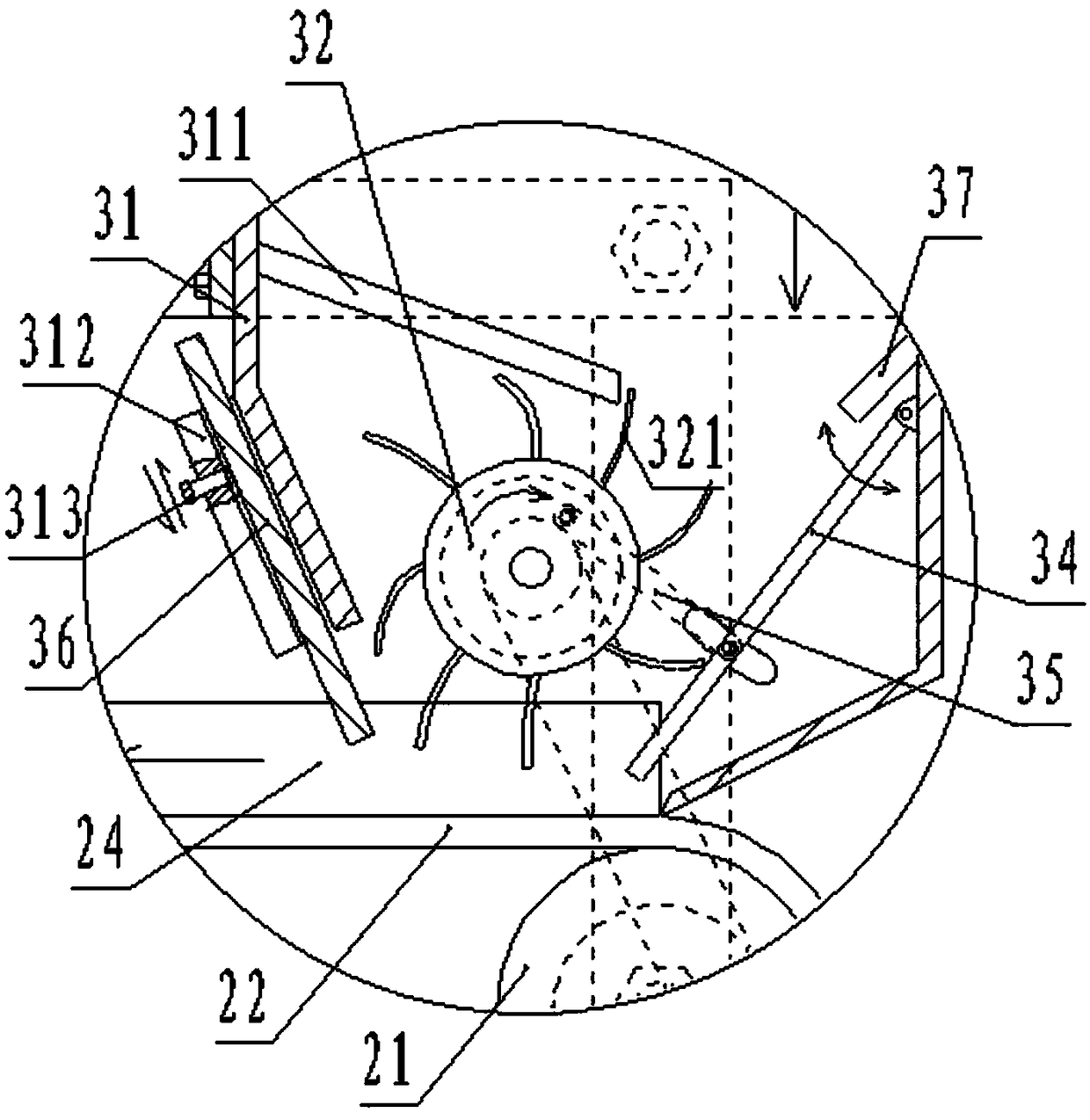

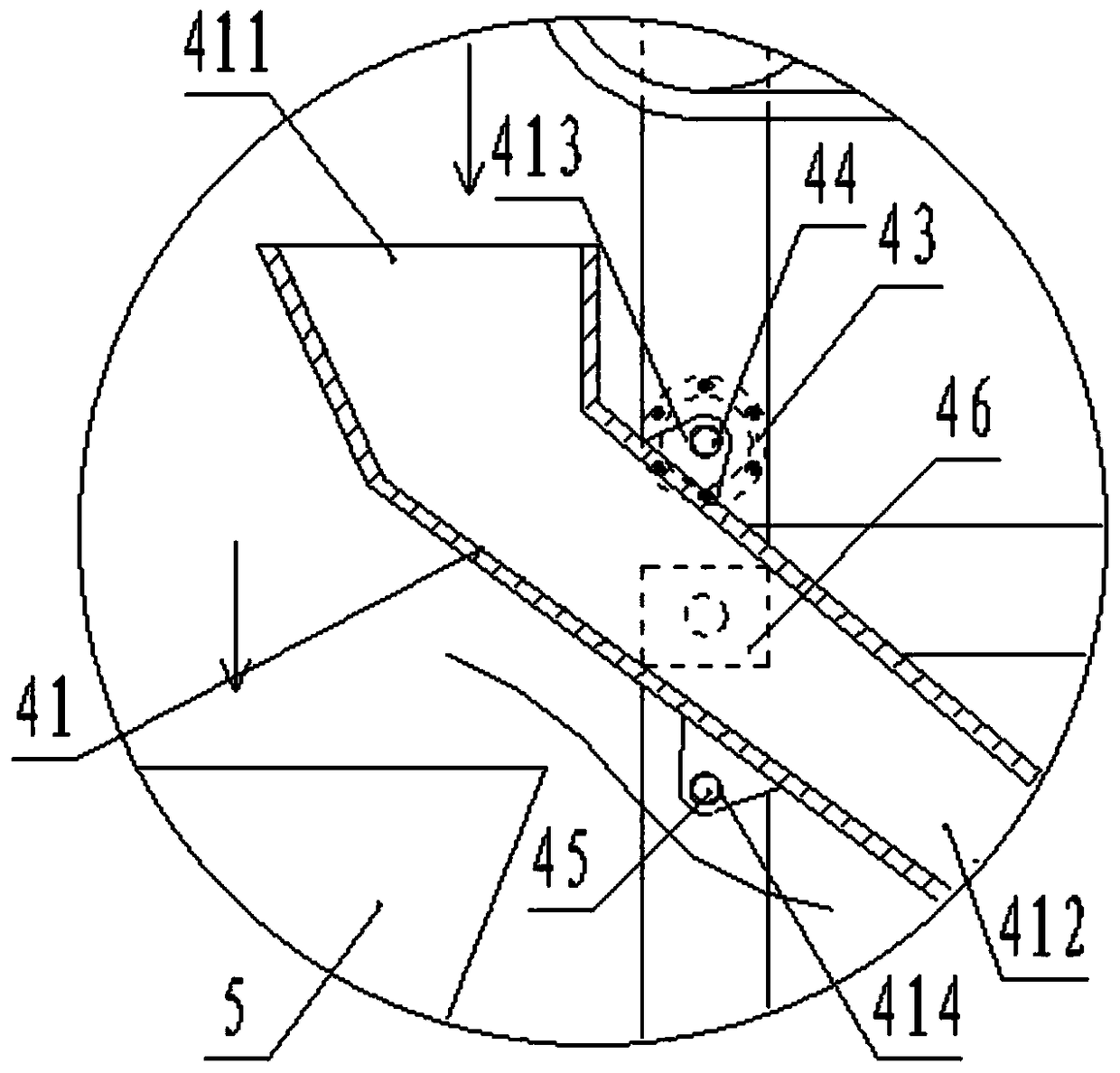

[0027] Such as Figure 1-7 As shown, the concrete structure of the present invention is: a kind of wood chips dynamic sampling machine, comprises frame 1, and described frame 1 is provided with spreader device 2 (for spreading out wood chip raw material into loose, and material with uniform cross section) flow), the spreader device 2 includes a spreader roller 21, a conveyor belt 22 and a spreader motor 23, the spreader roller 21 is relatively arranged on the frame 1, and the spreader motor 23 is connected to the spreader roller 21 by transmission , both sides of the conveyor belt 22 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com