Charging structure of mobile robot

A mobile robot and charging structure technology, applied in the field of mobile robots, can solve problems such as low accuracy rate, inconvenient use, complicated operation, etc., and achieve the effect of enhancing reliability and improving docking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

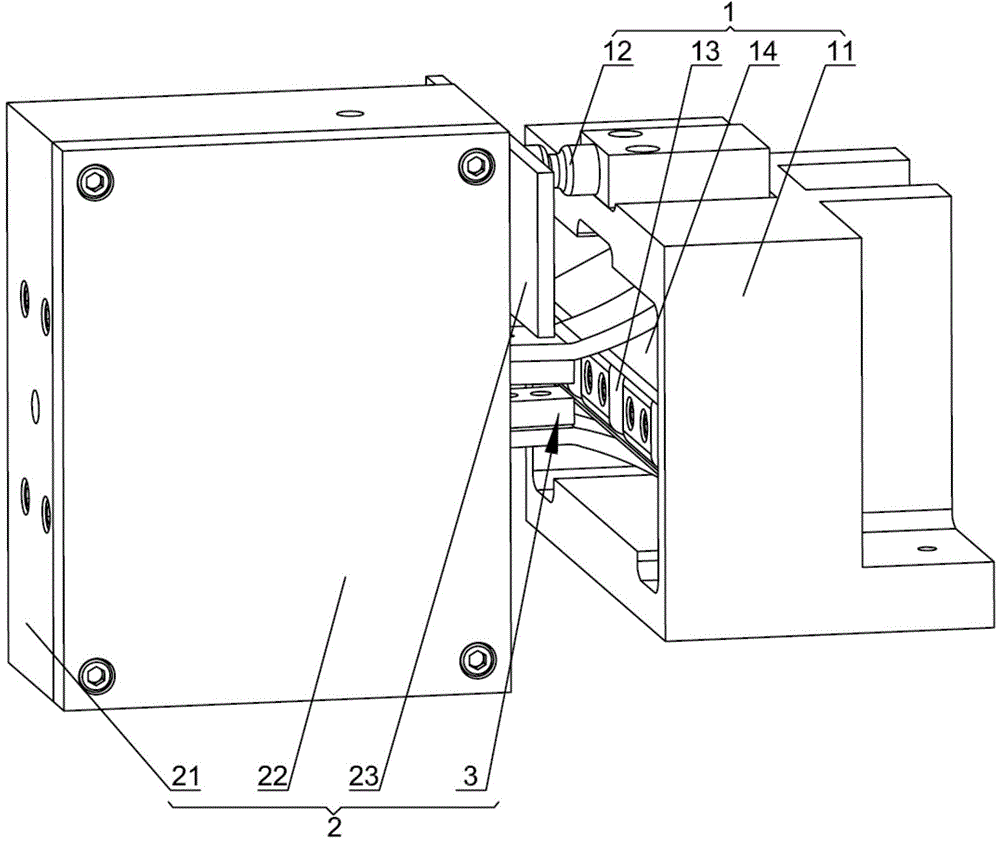

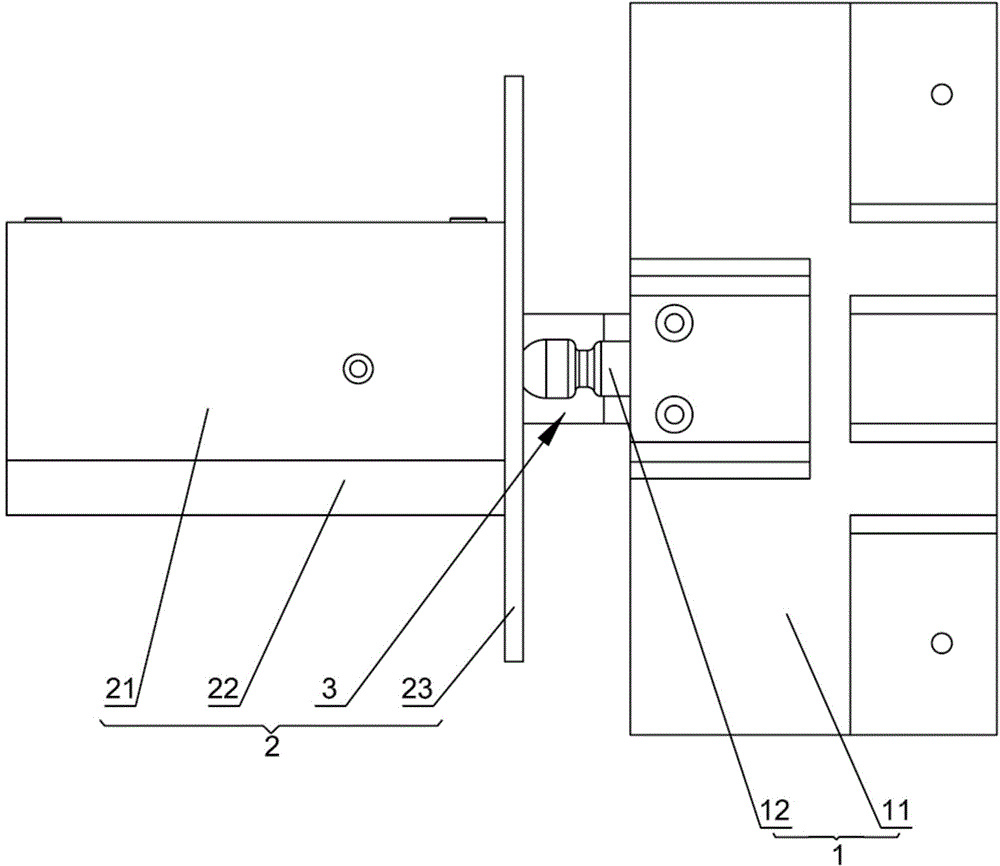

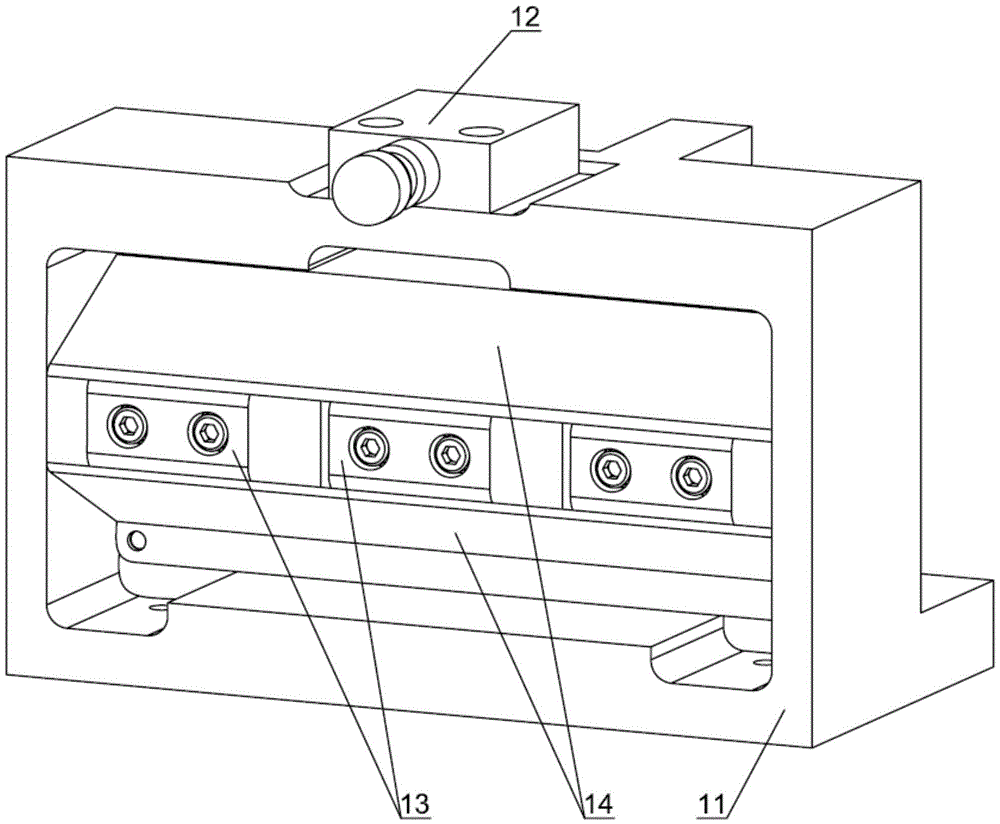

[0018] The invention provides a mobile robot charging structure, as attached figure 1 As shown, it includes a charging female assembly 1 fixedly connected to the tail of the mobile robot and a charging male assembly 2 fixedly connected to the charging pile. as attached image 3 And attached Figure 4 As shown, the charging female head assembly 1 includes a female head base 11 and a travel switch 12 connected to the braking device of the mobile robot. The travel switch 12 is fixedly connected to the female head base 11, and the female head base 11 is fixedly connected side by side Three pieces of insulating pillows 13 with trapezoidal cross-sections are fixedly connected with female contact copper sheets 14 on the slopes of the insulating pillows 13 .

[0019] as attached Figure 5 As shown, the charging male assembly 2 includes a male base 21 provided with a cavity 21a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com