Method for optimizing product planned maintenance interval by civil airplane manufacturer

A civil passenger aircraft, maintenance interval technology, applied in the aviation field, can solve problems such as insufficient comprehensiveness, poor engineering practicability, and no established feasible methods or processes, and achieves the effect of reducing maintenance costs and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

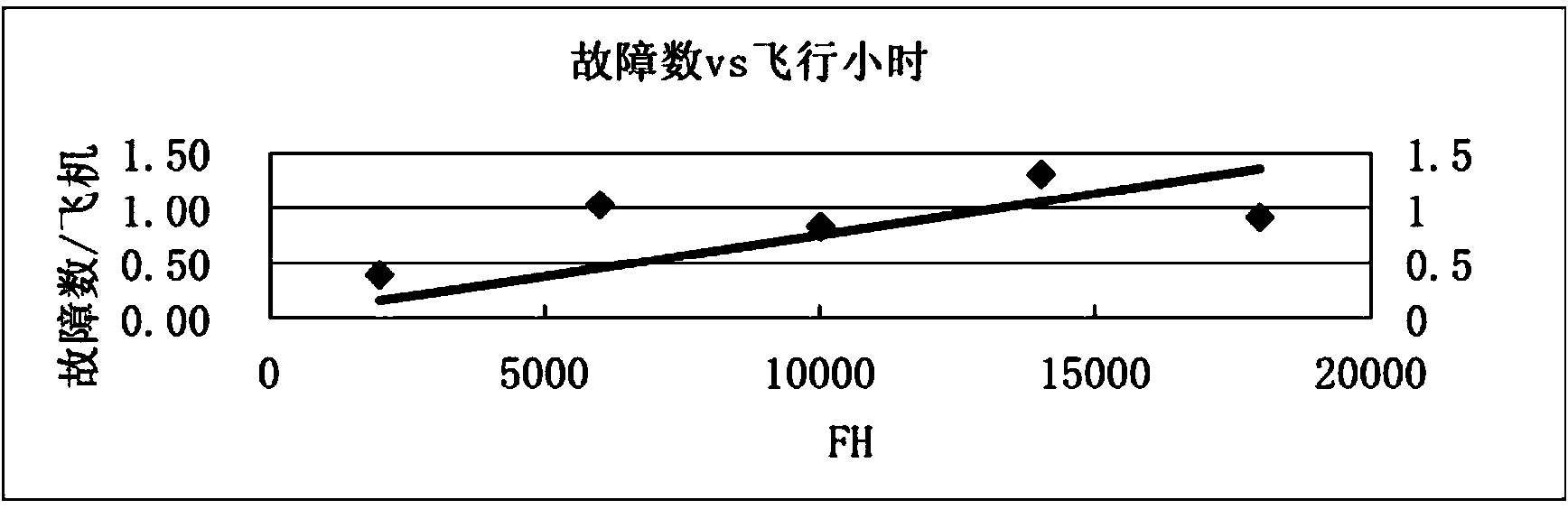

[0085] The total amount of the global fleet of a certain model is 527, and the invention is adopted for 4000FH (C inspection) and 4-year inspection and maintenance tasks in MRBR. According to the analysis, 234 of the 527 aircraft mainly operate in cold and arid regions, 285 operate in temperate rural areas, 8 operate in tropical regions, and a total of 77 aircraft are affected by coastal climates.

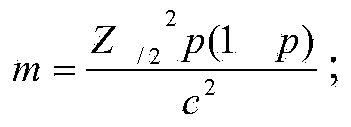

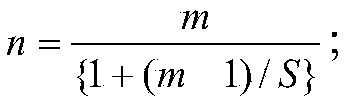

[0086] Sampling according to the method of step 2): According to the distribution of the fleet, the sampling sample must reflect 56% of the temperate and tropical climate and 44% of the cold and arid climate. Through the calculation of sample size selection, if it can represent the situation of the entire fleet, at least 70 aircraft / 264 inspections are required for the 4000FH (C inspection) mission, and at least 157 aircraft / 157 inspections are required for the 4-year mission. Major air operators And sample samples are as follows:

[0087] Operator 1: In temperate and tropical rur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com