Locomotive vehicle running gear bearing holder fault pre-alarm method

A technology for bearing cages and running parts, which is applied in the field of state monitoring and fault diagnosis of rotating machinery, and can solve problems such as unsatisfactory bearing fault diagnosis, easy to be interfered by other information, and major maintenance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

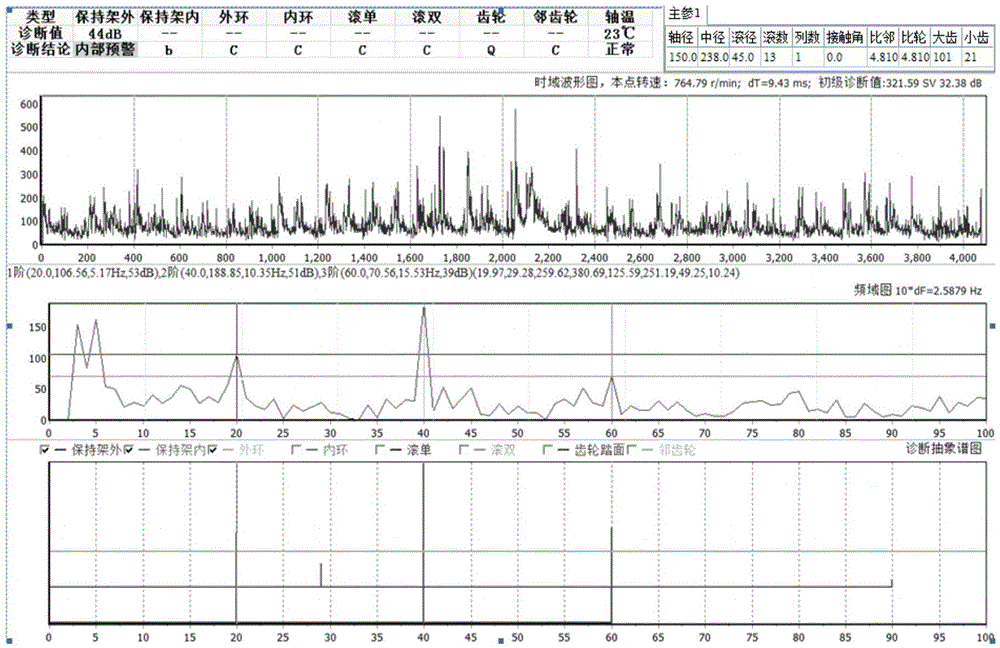

Image

Examples

Embodiment

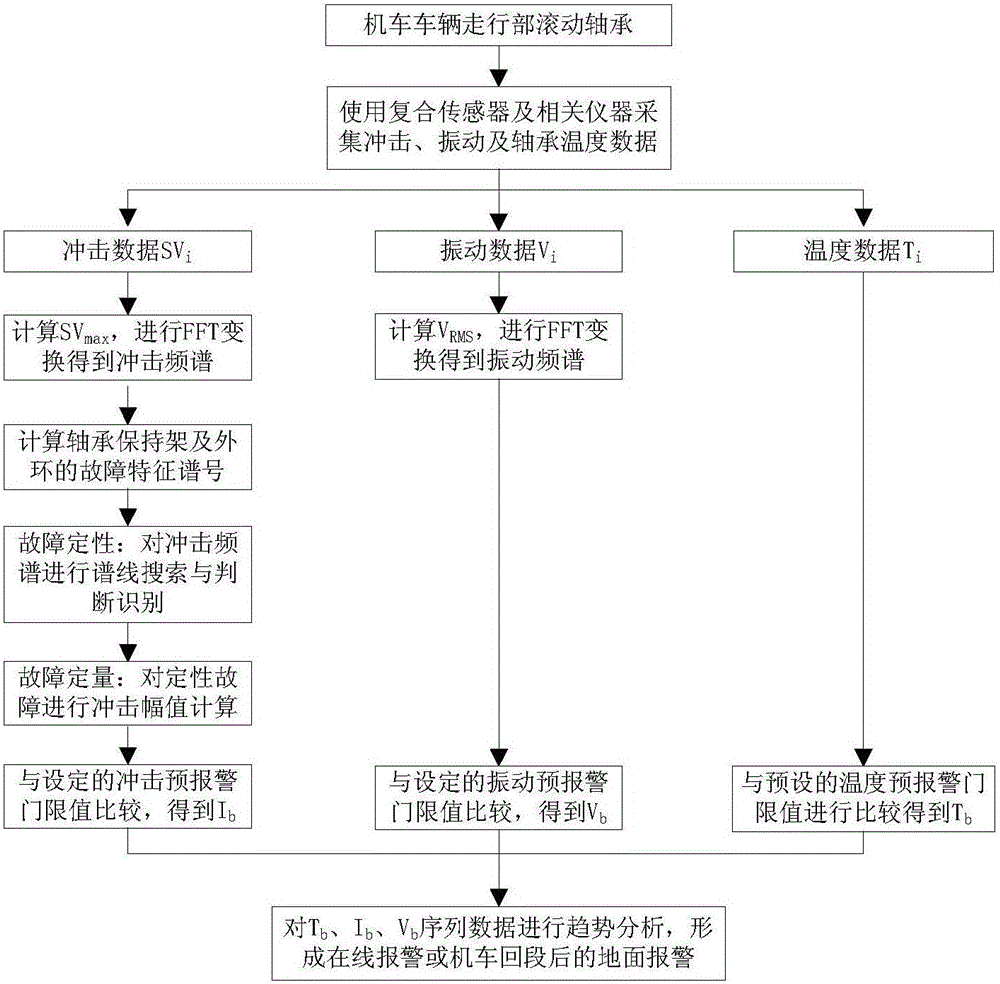

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

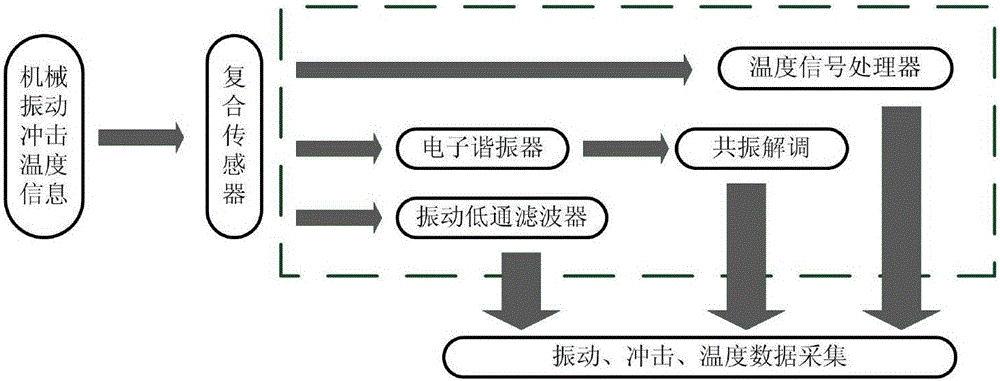

[0065] as attached figure 1 As shown: the present embodiment is a method for pre-alarming the failure of the bearing cage of the running part of the rolling stock, including the following steps:

[0066] (1) Install a composite sensor and a detection instrument on the bearing housing of the running part of the rolling stock. The composite sensor and detection instrument can detect shock, vibration and temperature, and collect shock data, vibration data and temperature data online during the running of the rolling stock ; Among them, temperature, vibration and shock detection adopt the patents "A Vibration and Shock Composite Sensor for Improving Low Frequency Characteristics" (CN201210558707.5), "A Generalized Resonance Composite Sensor for Detecting Vibration and Shock" (CN200810200735.3) and "A Kind of Vibration and Shock Composite Sensor" (CN20081020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com