Task reliability state-based manufacturing system predictive maintenance method

A manufacturing system and reliability technology, applied in manufacturing computing systems, forecasting, instruments, etc., can solve problems such as failure of enterprises to formulate maintenance strategies, safety accidents, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

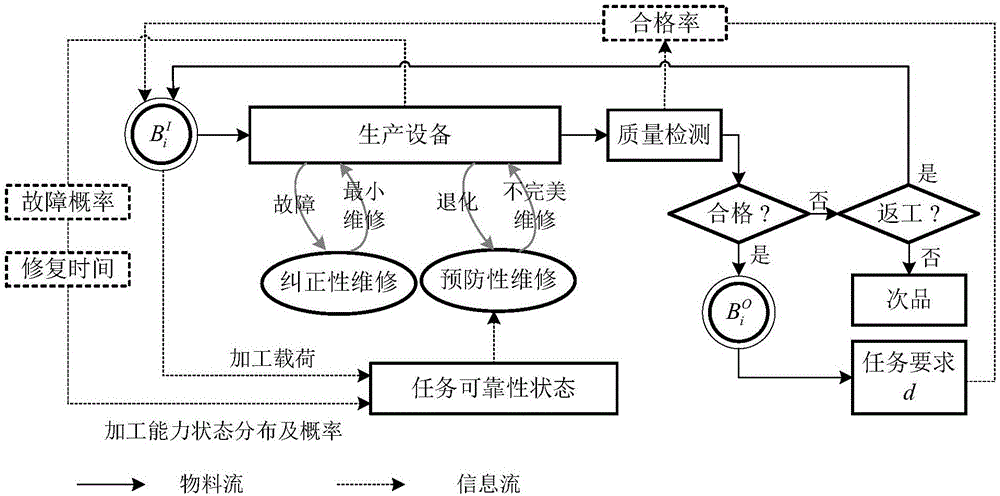

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

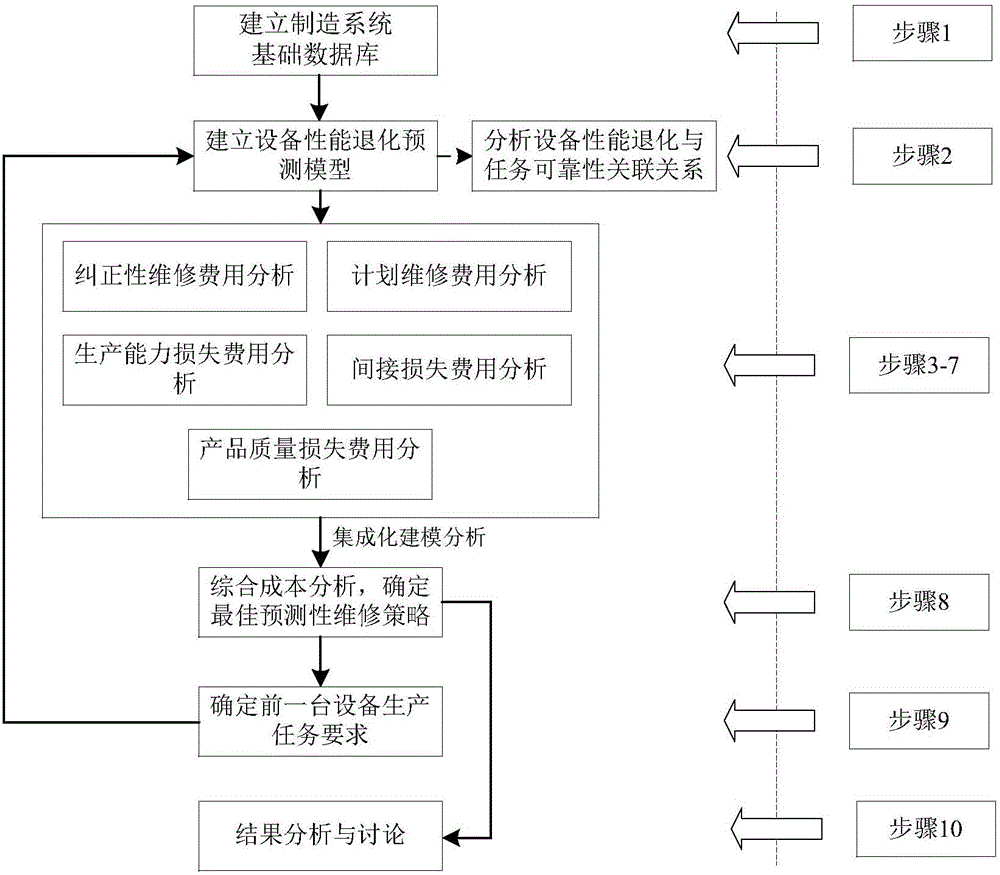

[0075] The present invention is a method for predictive maintenance of manufacturing systems based on task reliability status, see figure 2 As shown, its implementation steps are as follows:

[0076] Step 1 Collect the product quality information of the cylinder head of a certain model of four-cylinder diesel engine. Use quality function deployment to decompose and map key quality characteristics, and identify key processes and production equipment related to the engine cylinder head manufacturing system, as shown in Table 1 below. Then collect the failure, maintenance, quality inspection and operation inspection data of each related processing equipment respectively.

[0077] Table 1. Critical quality characteristics and their manufacturing process information

[0078]

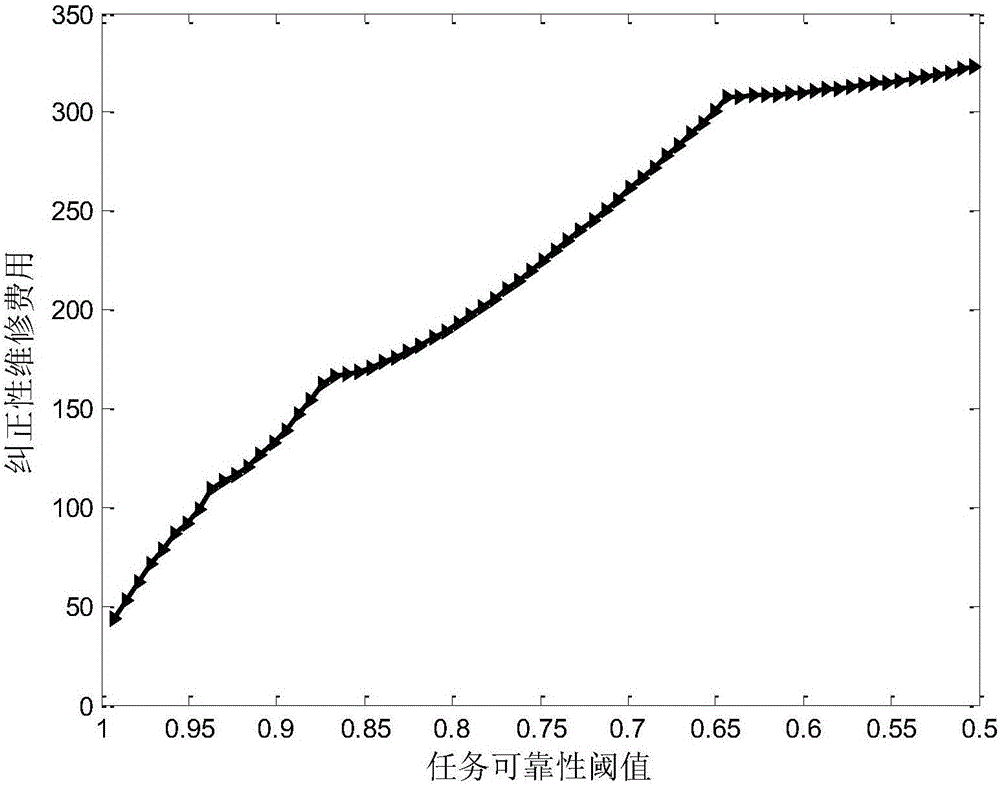

[0079] Step 2 on device a 5 Analysis of the basic data, according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com