Self-loading system early failure predicting method based on multi-field information fusion

An automatic loading system and early failure technology, applied in the directions of weapon accessories, ammunition supply, offensive equipment, etc., can solve problems such as difficulty, high requirements, and failure to predict the early failure of the automatic loading system, so as to improve the accuracy and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

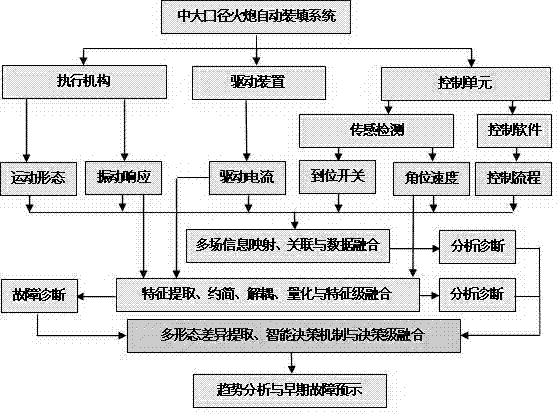

[0020] like figure 1 As shown, an early failure prediction method for automatic filling system based on multi-field information fusion,

[0021] a. Acquisition of multi-physics raw data information

[0022] (1) Optimizing test points on each actuator of the automatic filling system, and arranging ICP piezoelectric acceleration sensors. Considering that the accelerometer has a wide frequency response range and is sensitive to the movement of the mechanism, it is an additional test link outside the automatic filling system. It should be as few as possible and precise, and the location of the measuring points needs to be optimized. The vibration response of multiple components (near the intersection of multiple components, closer to the high-speed collision point of the mechanism and the components that are prone to failure on the mechanism),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com