Double-filtering layer meander circular seam self-cleaning sieve tube

A filter layer and meandering technology, applied in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of residual material in the well, large pipe diameter, low permeability, etc., and achieve uniform size of filter cracks , Excellent sand control performance, high filter gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

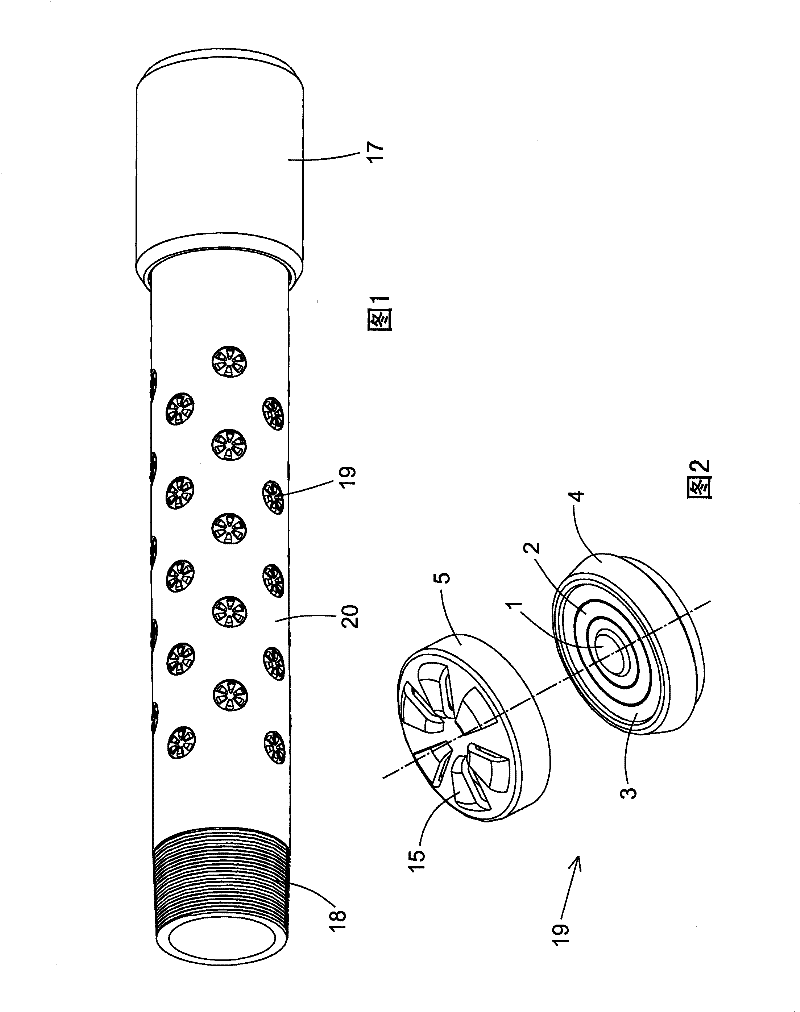

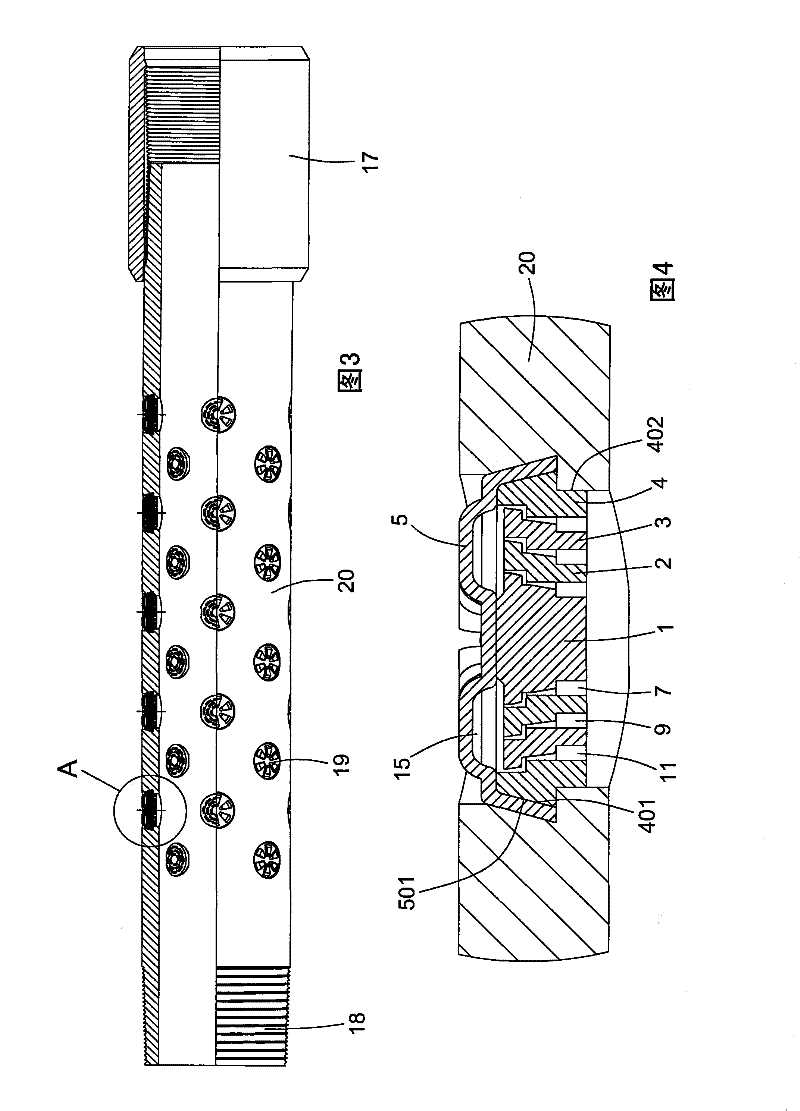

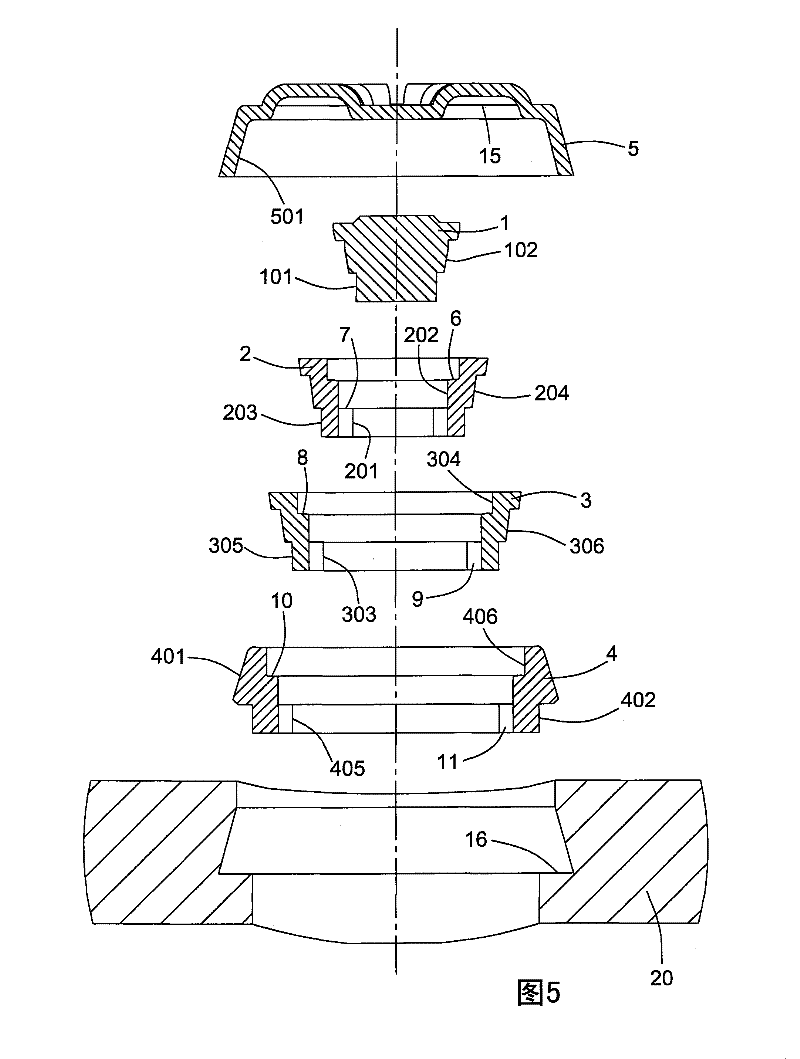

[0032] Label in the figure

[0033] 1 center cap 101 step face 102 step face

[0034] 2 filter rings

[0035] 201 step surface 202 step surface 203 step surface 204 step surface

[0036] 3 filter rings

[0037] 303 steps 304 steps 305 steps 306 steps

[0038] 4 retaining rings

[0039] 401 conical surface 402 cylindrical surface 405 stepped surface 406 stepped surface

[0040] 5 protective cover 501 inner wall surface

[0041] 6 steps 7 steps 8 steps 9 steps

[0042] 10 steps 11 steps 12 filter slots 13 filter slots

[0043] 14 filter seam 15 transom 16 stepped hole 17 coupling

[0044] 18 thread 19 filter element 20 base tube

[0045] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention is a self-cleaning screen with double filter layer meandering flow annular seam, which is composed of a filter element 19 and a base pipe 20. The filter element 19 consists of a central cap 1, two filter rings 2, 3, a fixed ring 4, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com