Straight slit trapezoidal self-cleaning screen pipe

A trapezoidal, self-cleaning technology, applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of low strength, poor filtration accuracy, low permeability, etc., and achieve uniform size and excellent sand control performance , The effect of small penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Label in the figure

[0019] 1 base tube 2 filter element 3 filter hole

[0020] 4 step surface 5 filter element 6 protective cover

[0021] 7 through hole 8 upper fixing ring 9 lower fixing ring

[0022] 10 filter bar 11 plane 12 arc surface

[0023] 13 slope 14 slope 15 filter seam

[0024] 16 External thread thread 17 Thread head 18 Coupling

[0025] 19 arc-shaped outwardly expanding horn mouth 20 sharp-angled outwardly expanding horn mouth

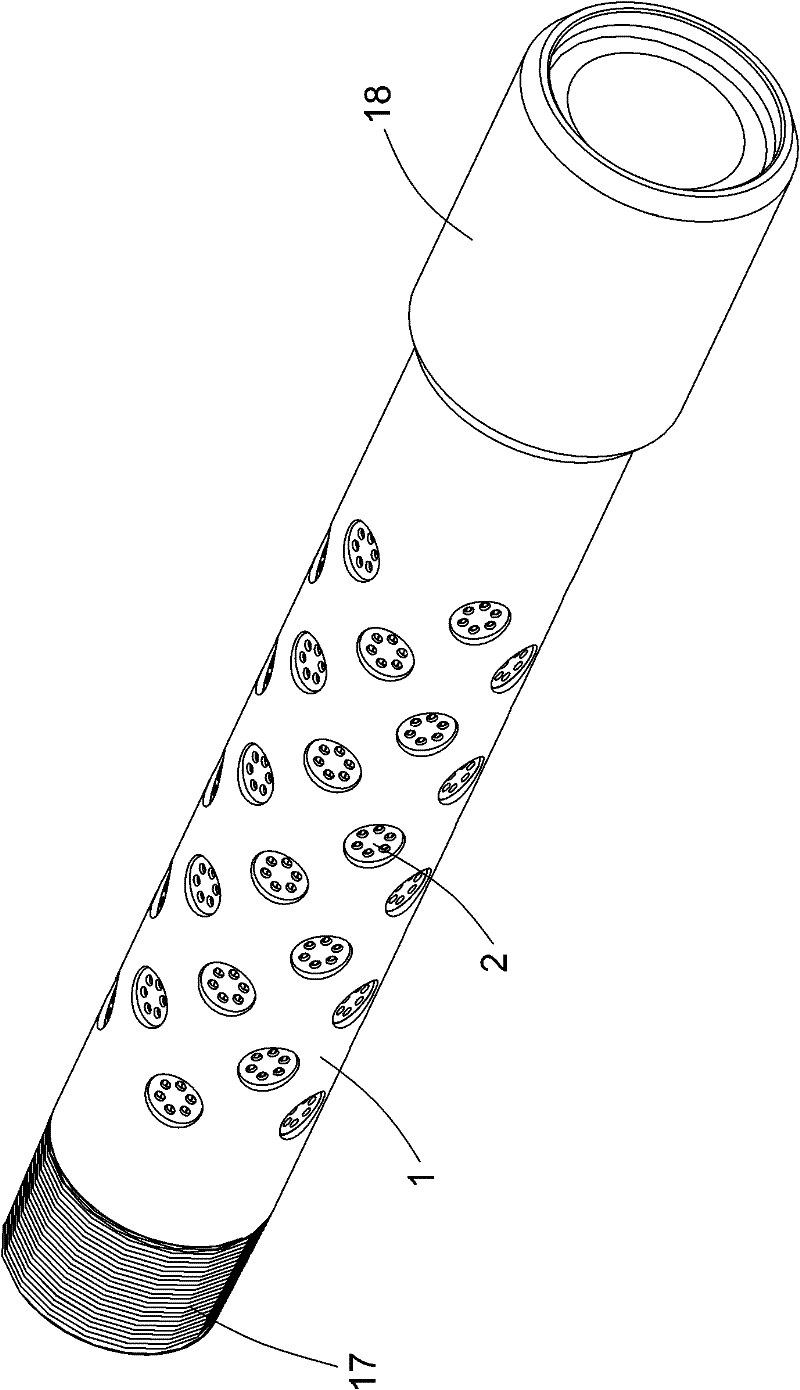

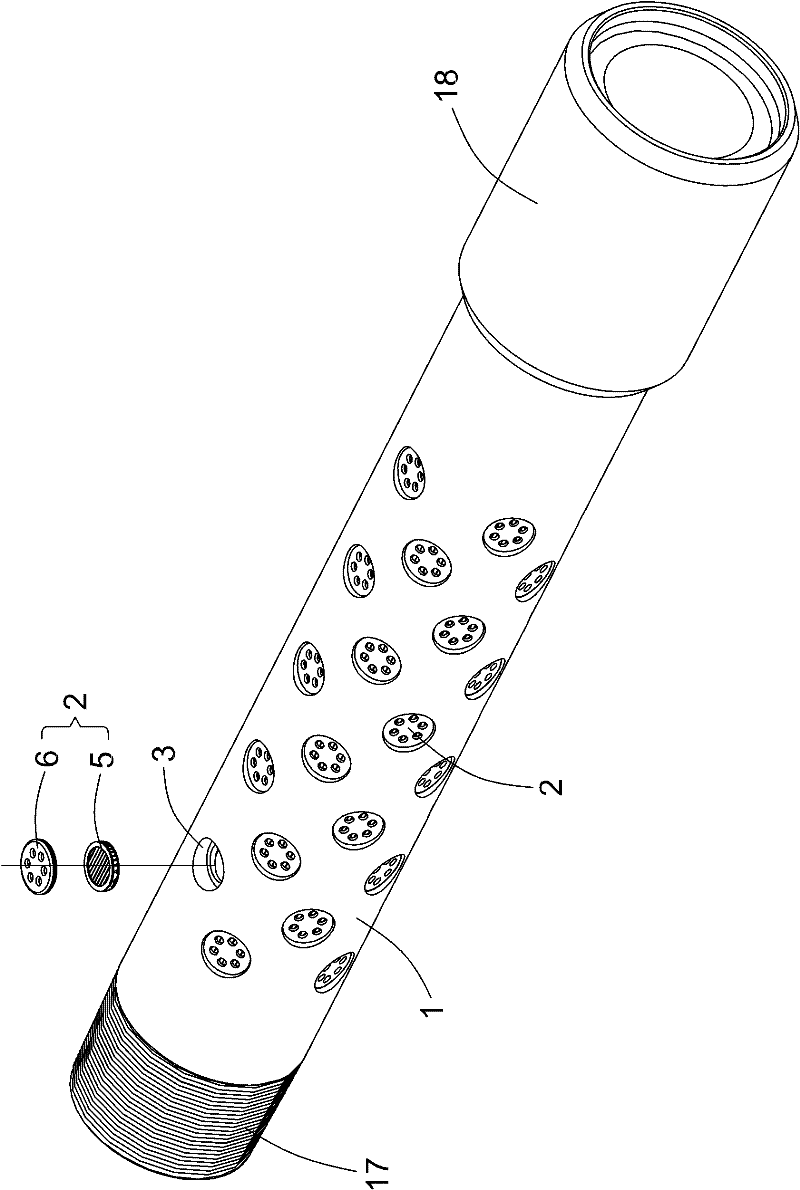

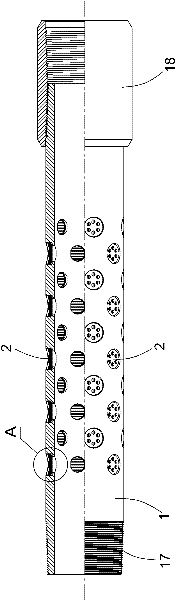

[0026] Please refer to figure 1 , figure 2 , image 3 , Figure 4 ; The present invention is a straight seam trapezoidal self-cleaning screen, which is composed of a base pipe 1 and a filter element 2. The filter element 2 is installed in the filter hole 3 on the side wall of the base pipe 1. The filter hole 3 is a filter hole with a stepped surface. 4 round holes.

[0027] Please refer to Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , The filter element 2 is composed of a filter element 5 and a prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com