Patents

Literature

40results about How to "Convenient downhole operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

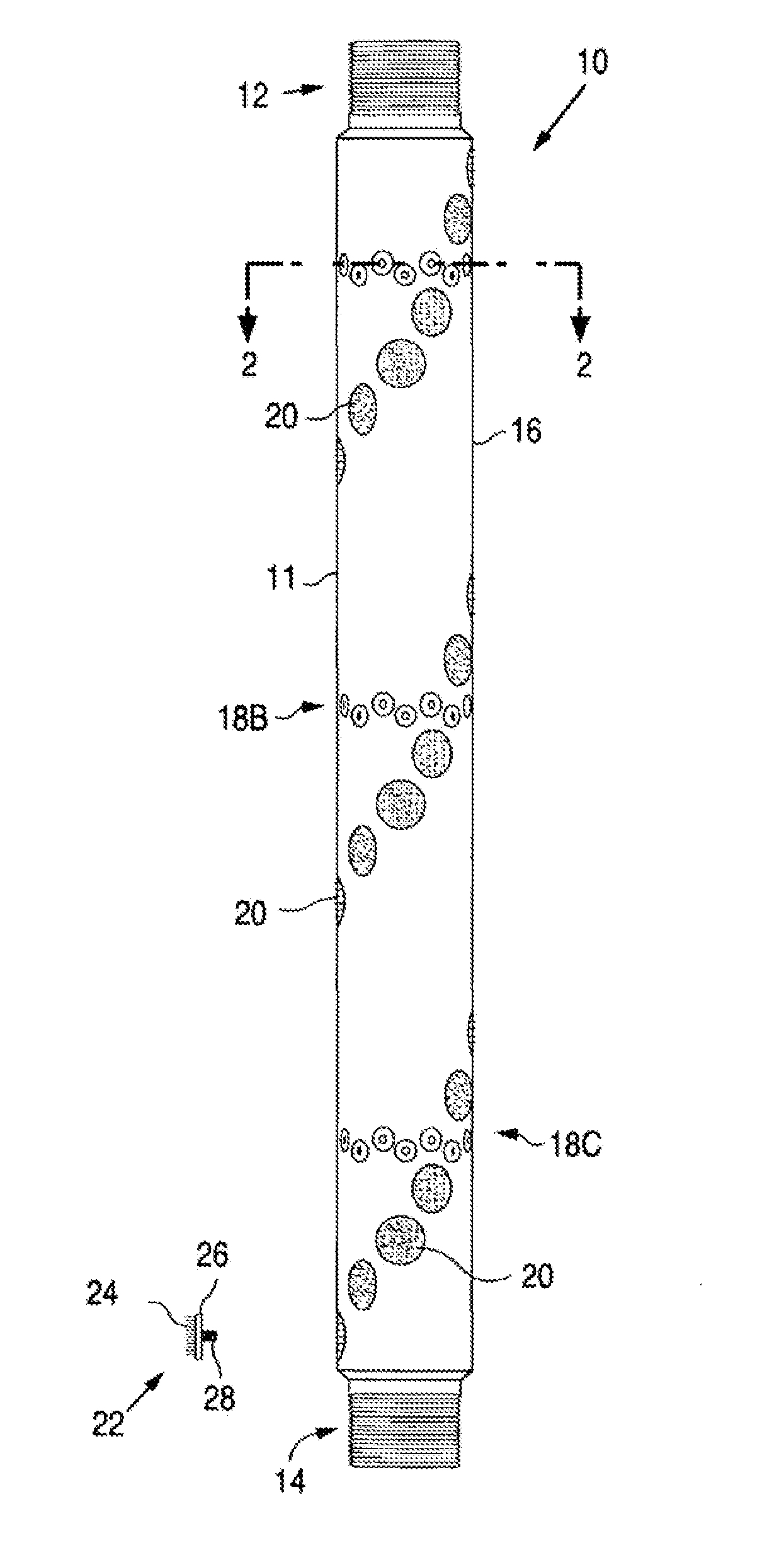

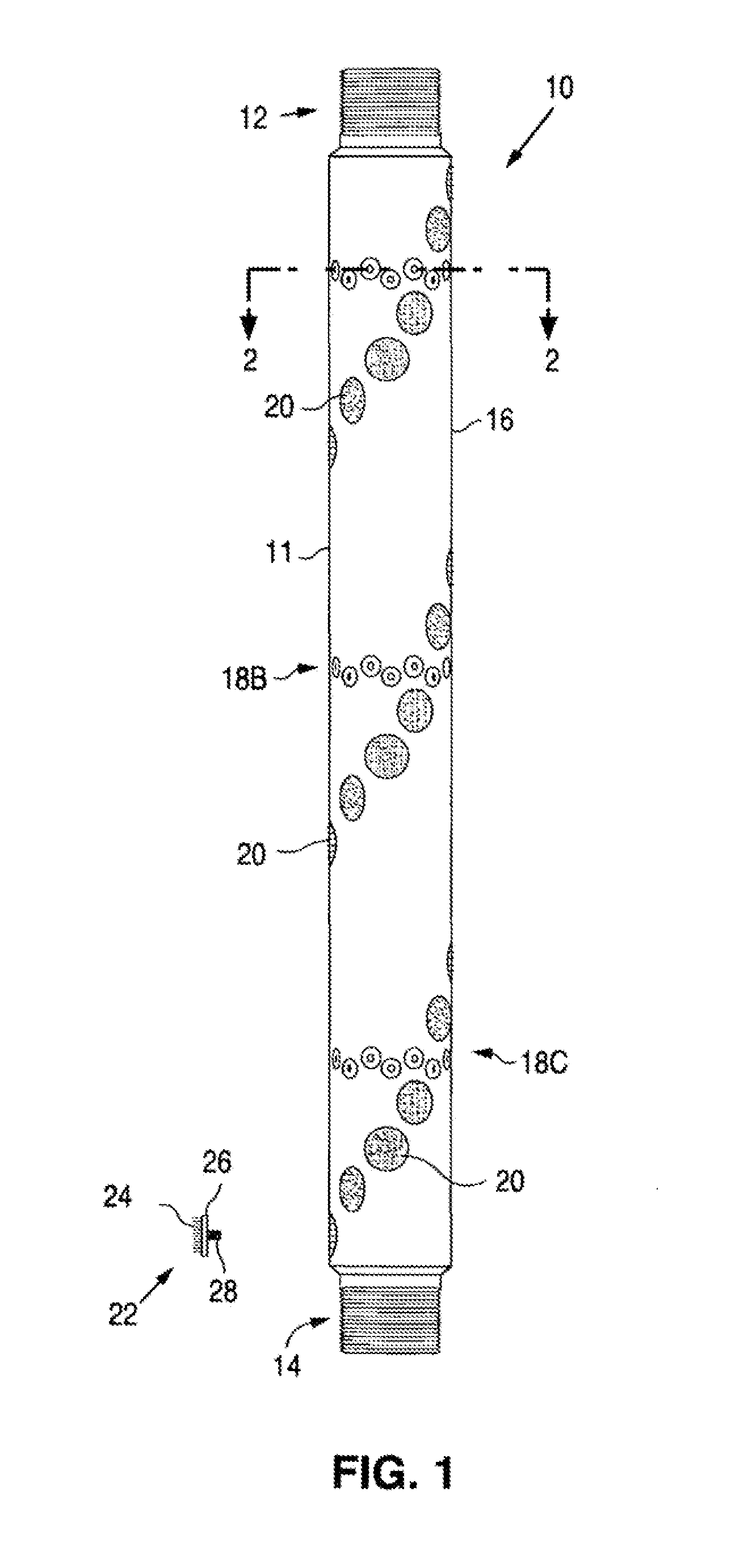

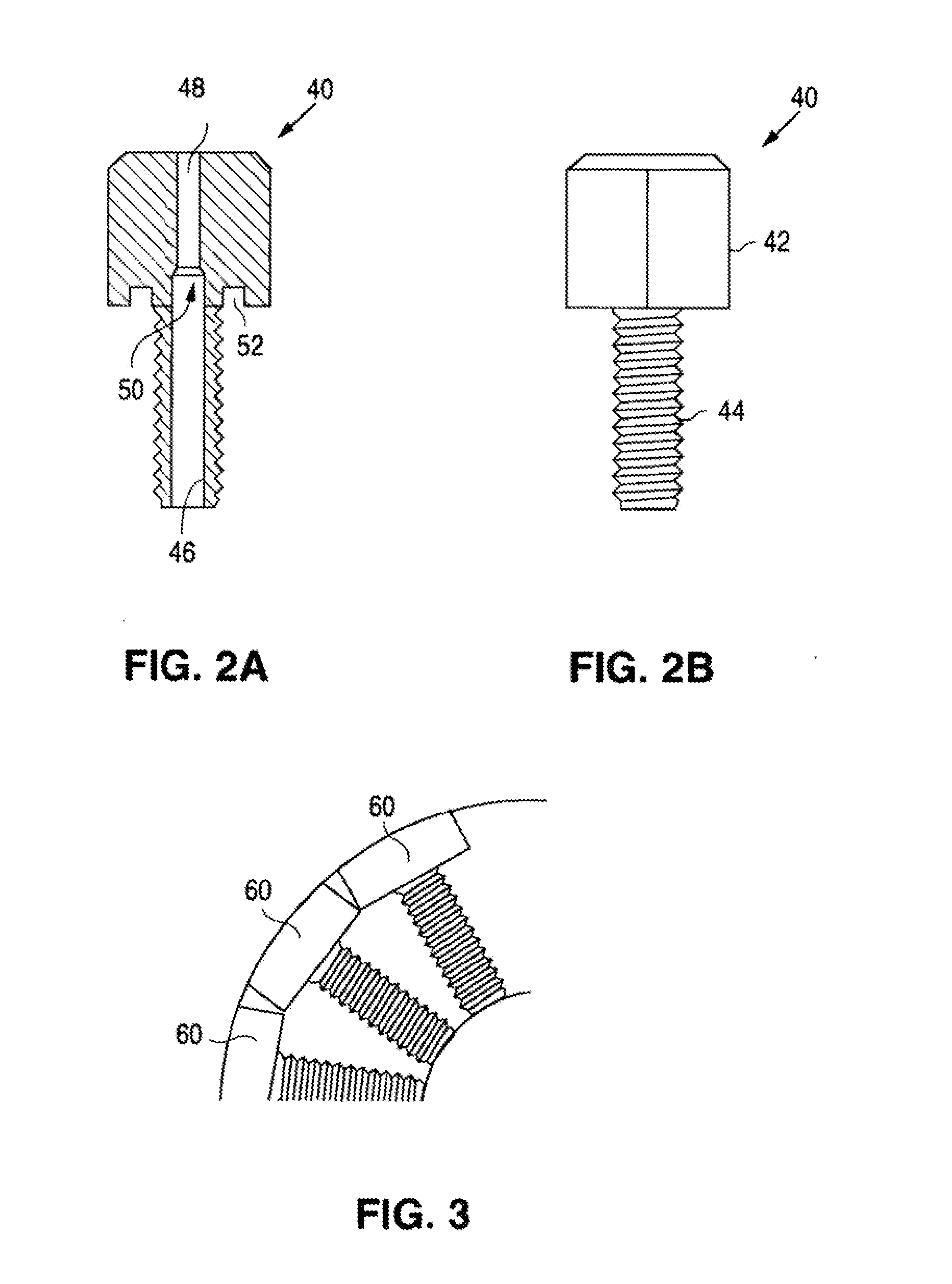

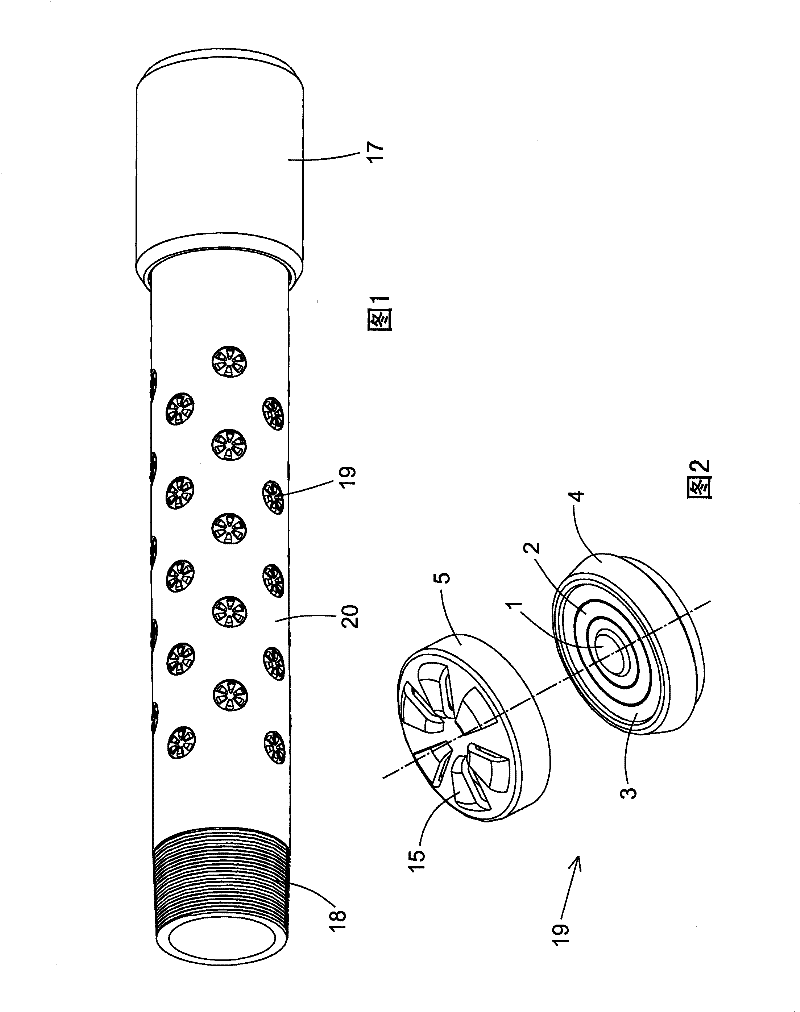

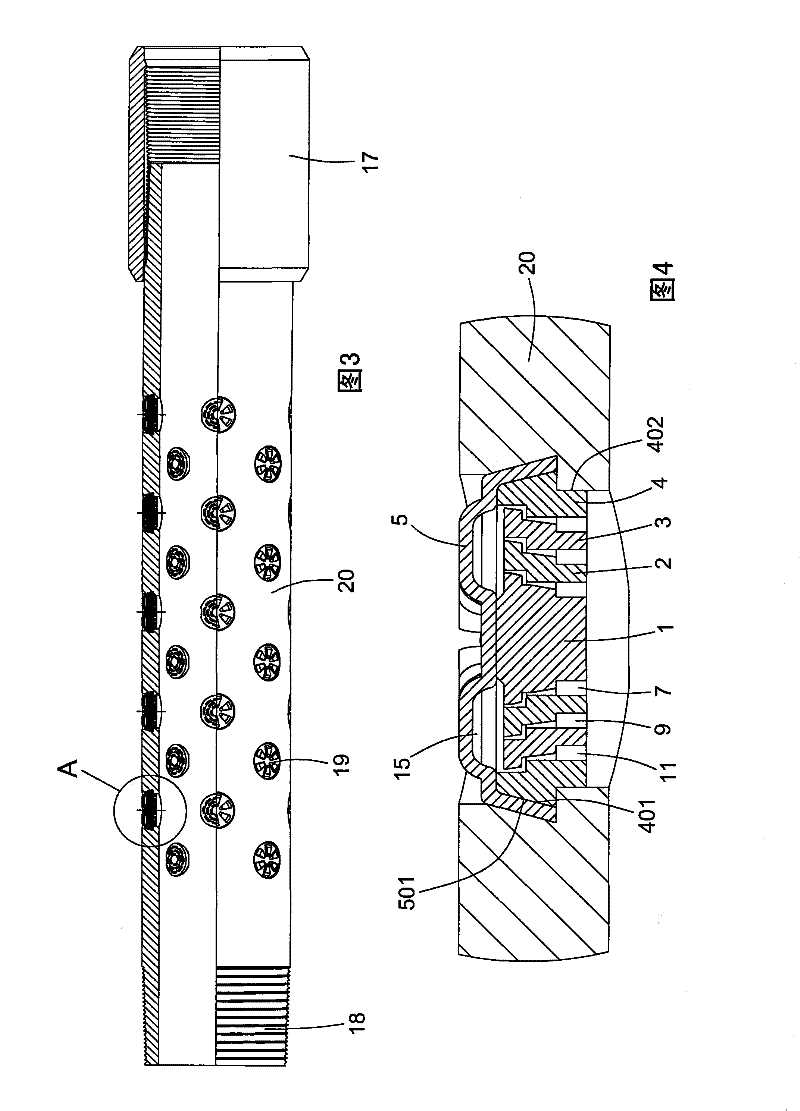

Devices, systems and methods relating to down hole operations

ActiveUS20130192818A1Convenient downhole operationPromote recoveryCleaning apparatusFluid removalEngineeringHigh pressure

Systems and method for improving down hole operations of well casings are disclosed herein. Systems and methods disclosed herein can comprise brushes, high pressure fluid outlets, and skids. Other systems and methods are disclosed herein.

Owner:HYPER SCRATCHER INC

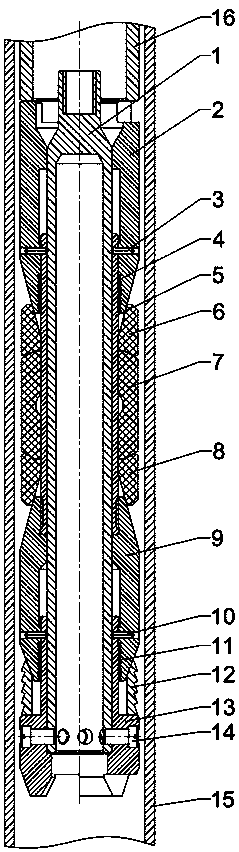

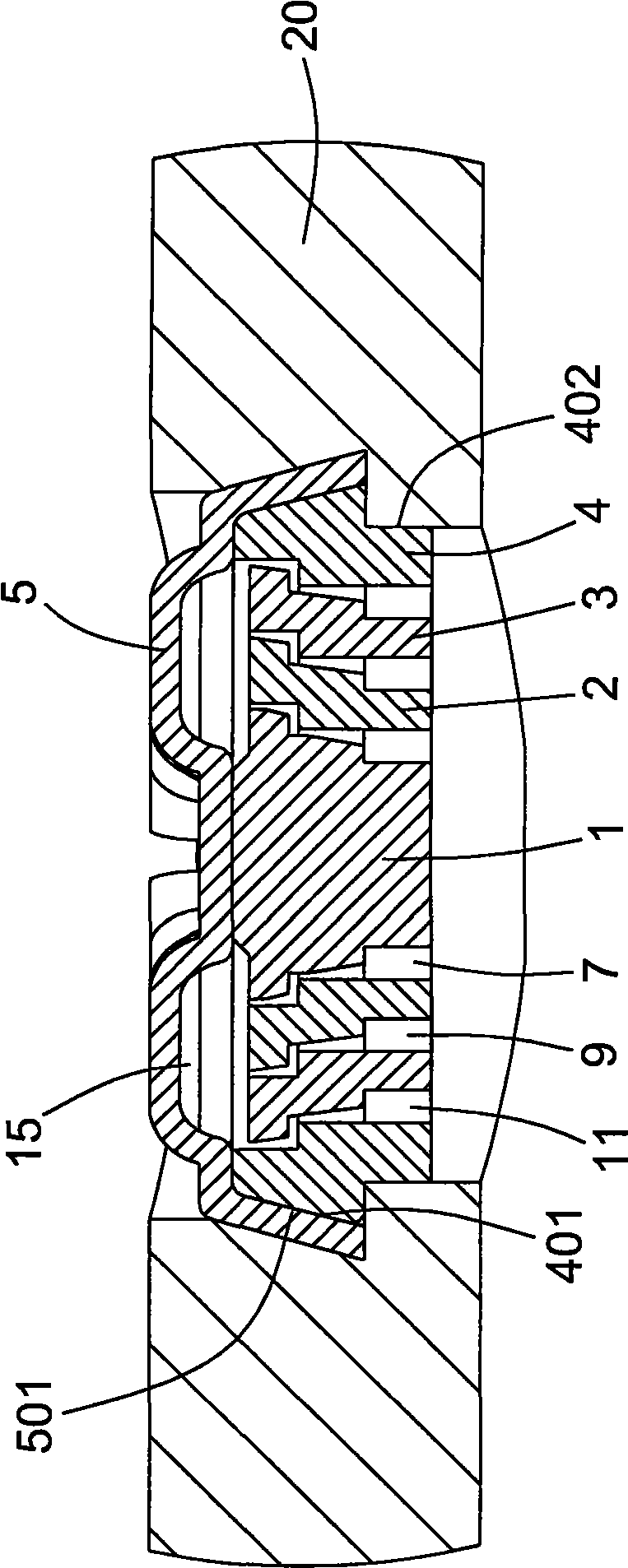

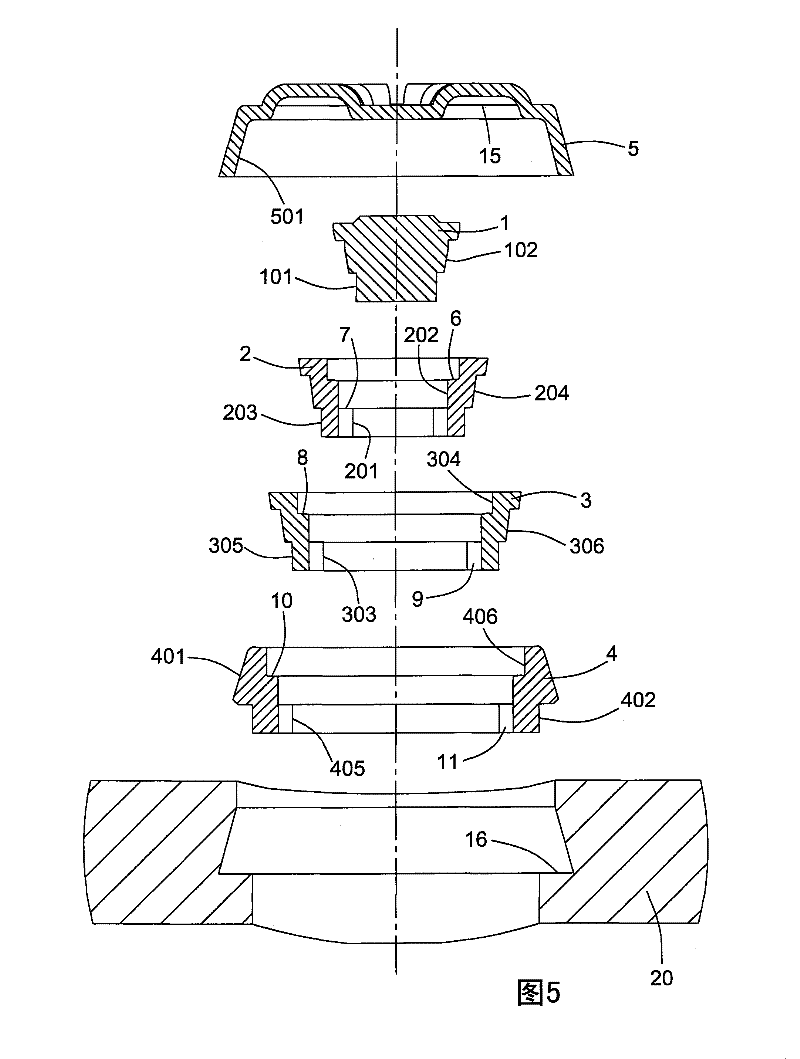

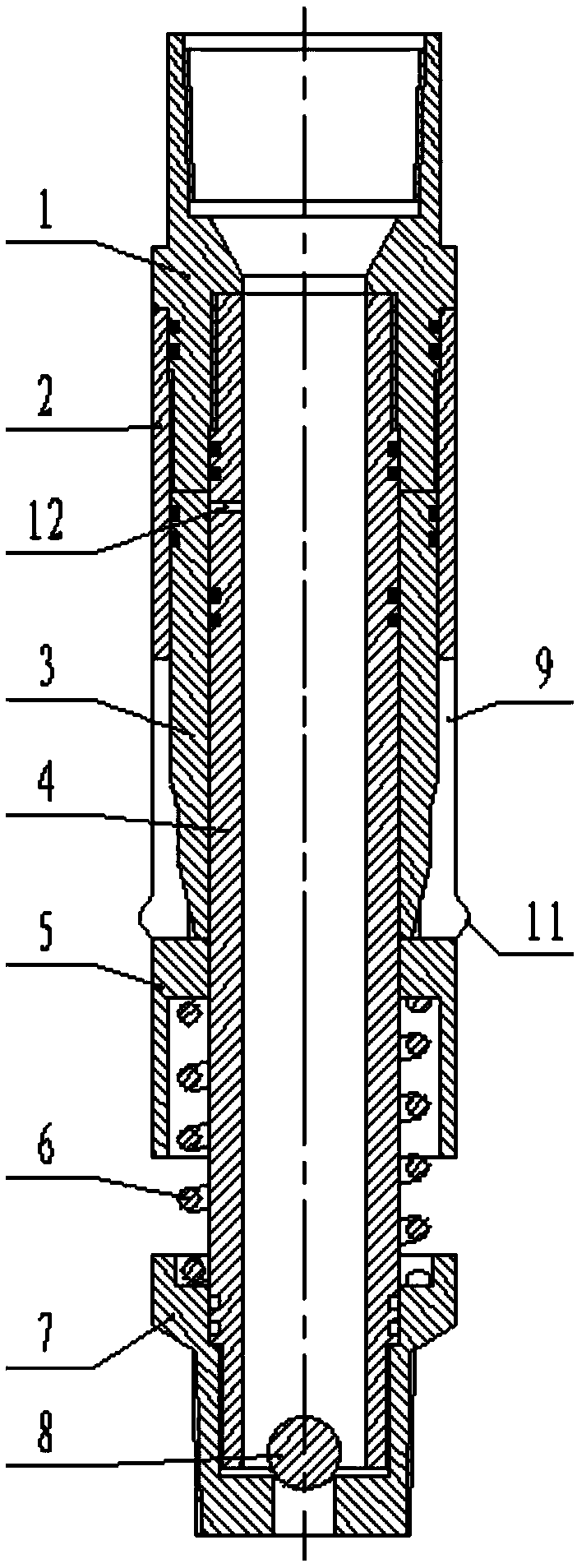

Single-slip large-diameter drilling-grinding-free composite bridge plug and setting method thereof

InactiveCN108343395ARealize production operationsAvoid problems such as long construction period, high operation cost and high construction riskSealing/packingEngineeringSingle slip

The invention discloses a large-diameter composite bridge plug which comprises a setting pull rod, an upper cone, a central pipe, a lower cone, a rubber cylinder assembly, a one-way integral slip, a guiding shoe head and a soluble fracturing ball. The upper cone, the central pipe, the lower cone and the guiding shoe head are sequentially mounted on the setting pull rod in a sleeving mode, the upper cone is connected with one end of the central pipe, and the end, close to the threaded end of the setting pull rod, of the upper cone is provided with an inward-sunken conical face matched with thesoluble fracturing ball; the end, connected with the central pipe, of the upper cone is in a conical shape, the lower cone is connected with one end of the central pipe through a thread, the other endof the lower cone is connected with one end of the guiding shoe head, and the central pipe is sleeved with the position between the upper cone and the lower cone, wherein the position is provided with the rubber cylinder assembly; and the guiding shoe head is provided with an abutting part, and the one-way integral slip is arranged between the lower cone and the abutting part of the guiding shoehead. According to the large-diameter composite bridge plug, drilling grinding is not needed, and the soluble fracturing ball is completely dissolved to provide an oil and gas production channel for awellbore.

Owner:SOUTHWEST PETROLEUM UNIV

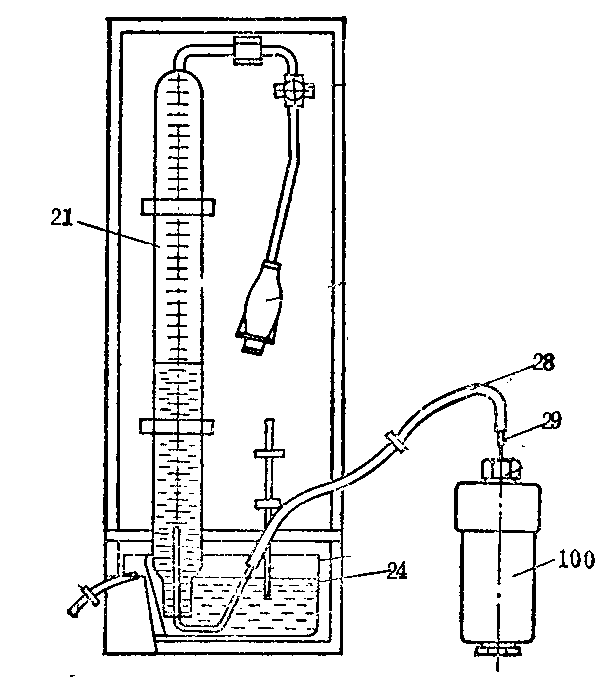

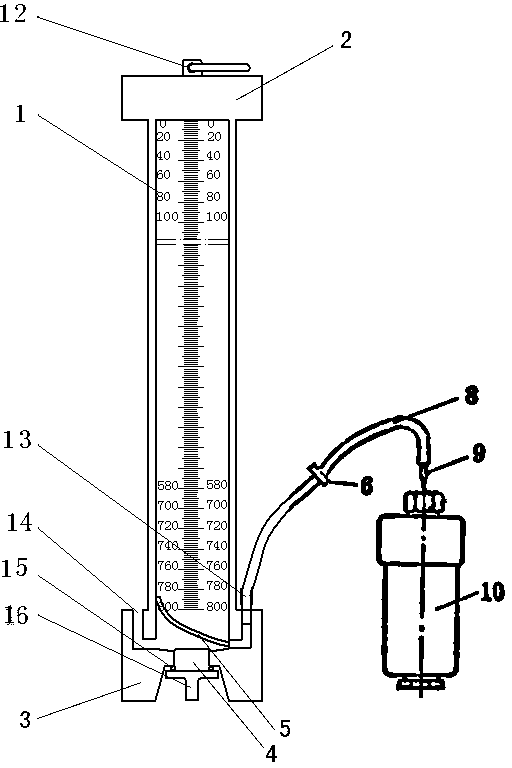

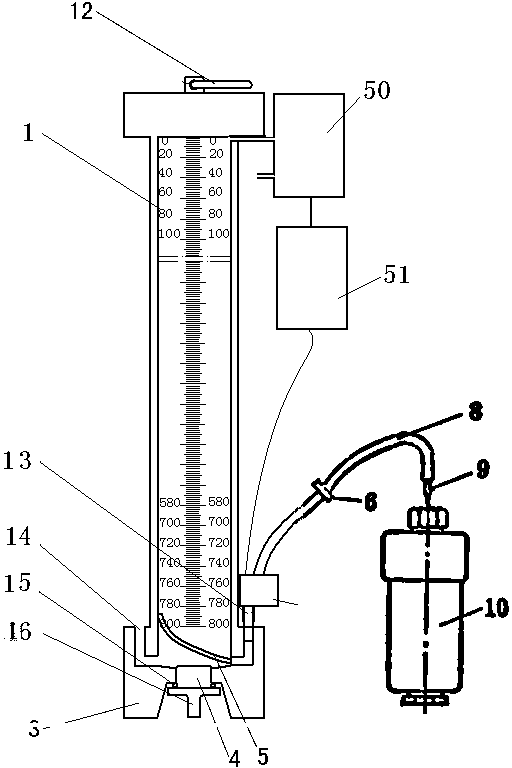

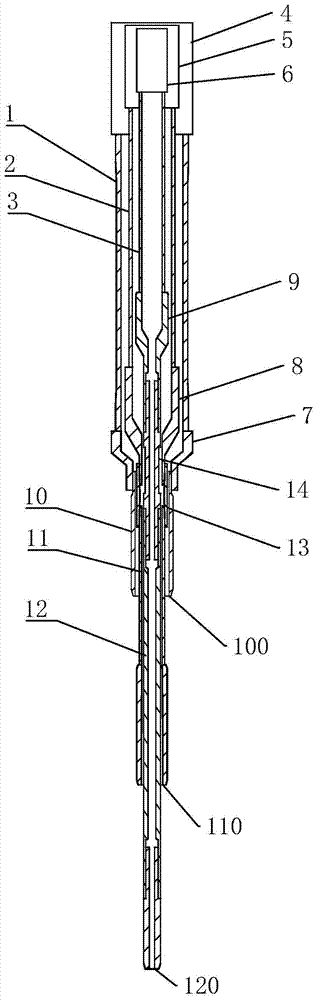

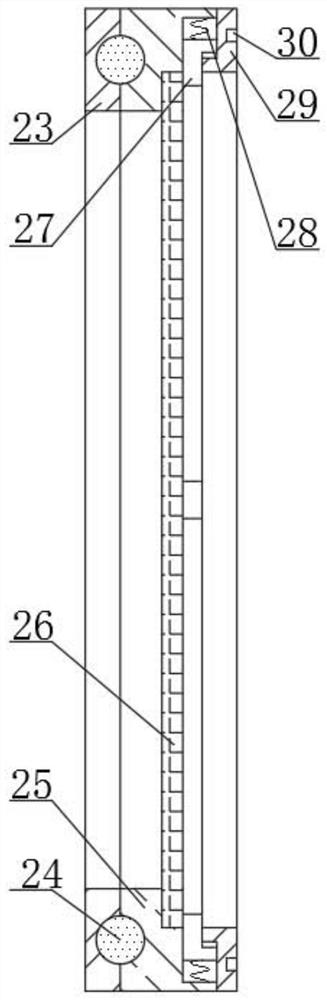

Gas desorption instrument

InactiveCN102706768ARealize smart measurementCompact structureMaterial analysisDesorptionEngineering

The invention relates to a gas desorption instrument. The gas desorption instrument comprises a measuring tube, an exhaust rubber tube and a puncture needle; an upper cover is arranged on the top of the measuring tube; a hoisting ring is arranged on the upper cover; a base is arranged at the bottom of the measuring tube; the base is provided with a water inlet; a plug is arranged on the water inlet; a water outlet is formed between the base and the measuring tube; a hose is arranged in the measuring tube; the base is provided with an air inlet; the hose is connected with the exhaust rubber tube through the air inlet; the exhaust rubber tube is connected with a coal sample tank through the puncture needle; and a spring clip is arranged on the exhaust rubber tube. The gas desorption instrument is simple and compact in structure, small in size, light in weight, easy to transport, convenient to carry and low in water consumption, facilitates wild or underground operation, and is suitable for water-free measuring sites; because the hoisting ring is arranged on the upper cover and the base is arranged at the lower end of the measuring tube, the instrument is easy to level; and when the instrument is used, the hoisting ring can be tied on a rope to hoist the instrument, or the instrument is placed on a horizontal plane.

Owner:CCTEG SHENYANG RES INST

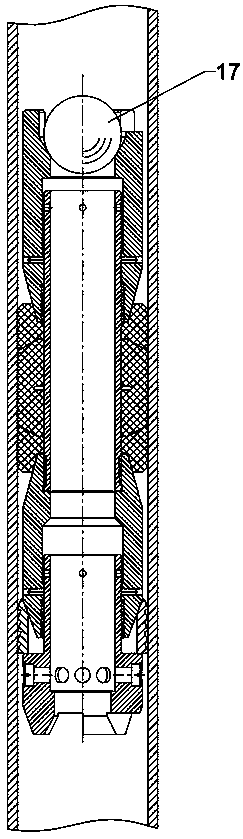

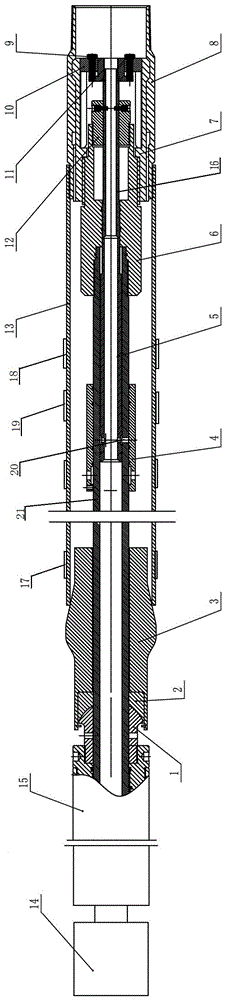

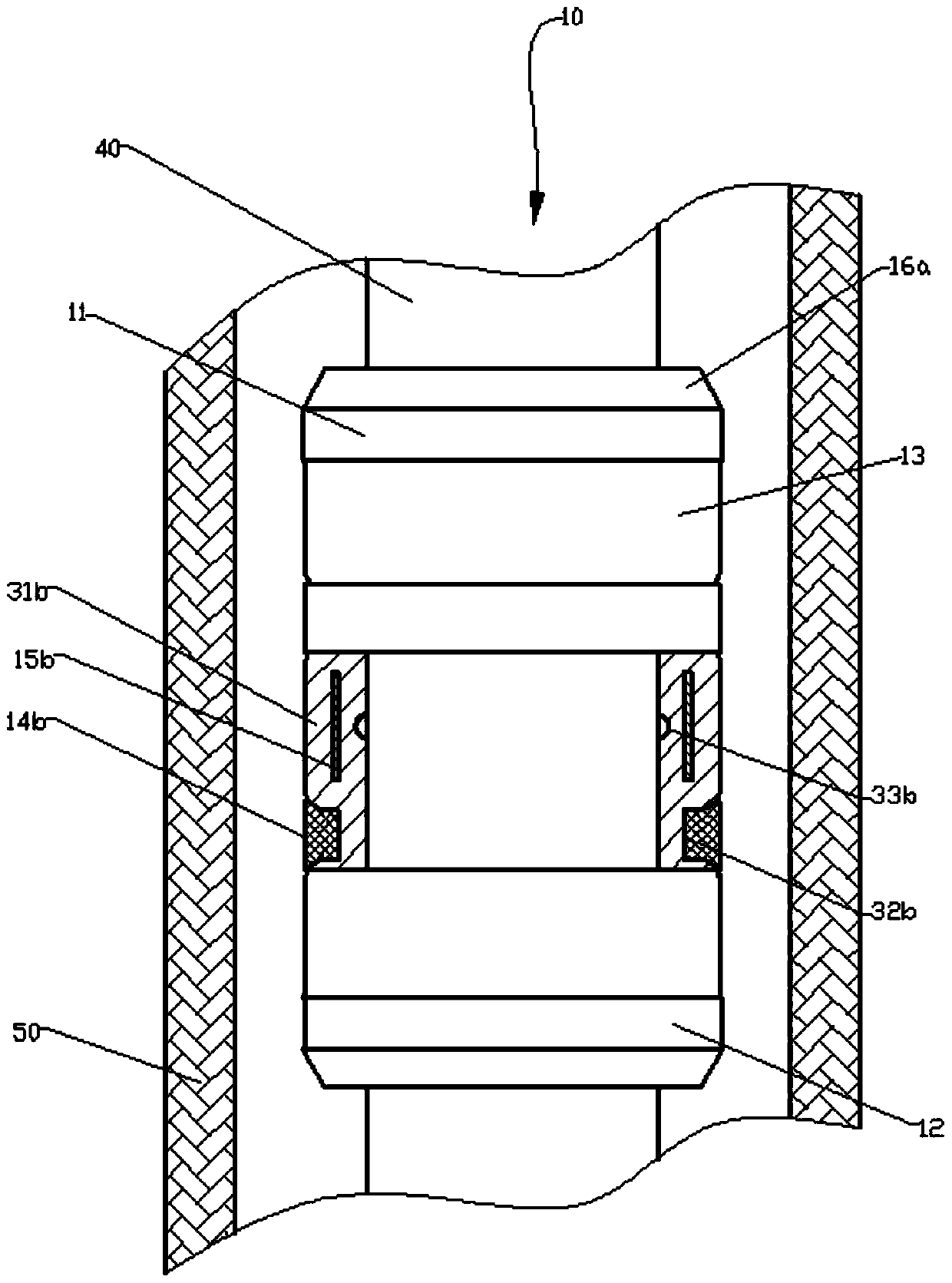

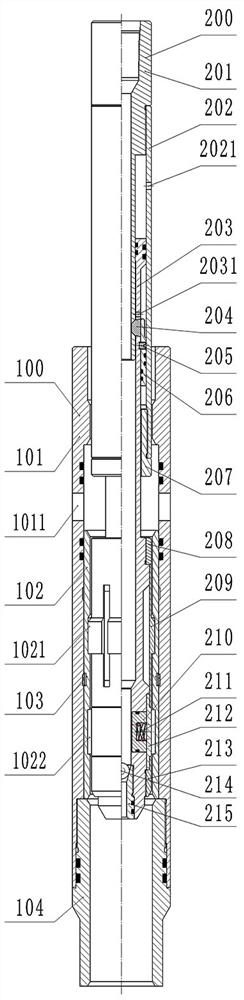

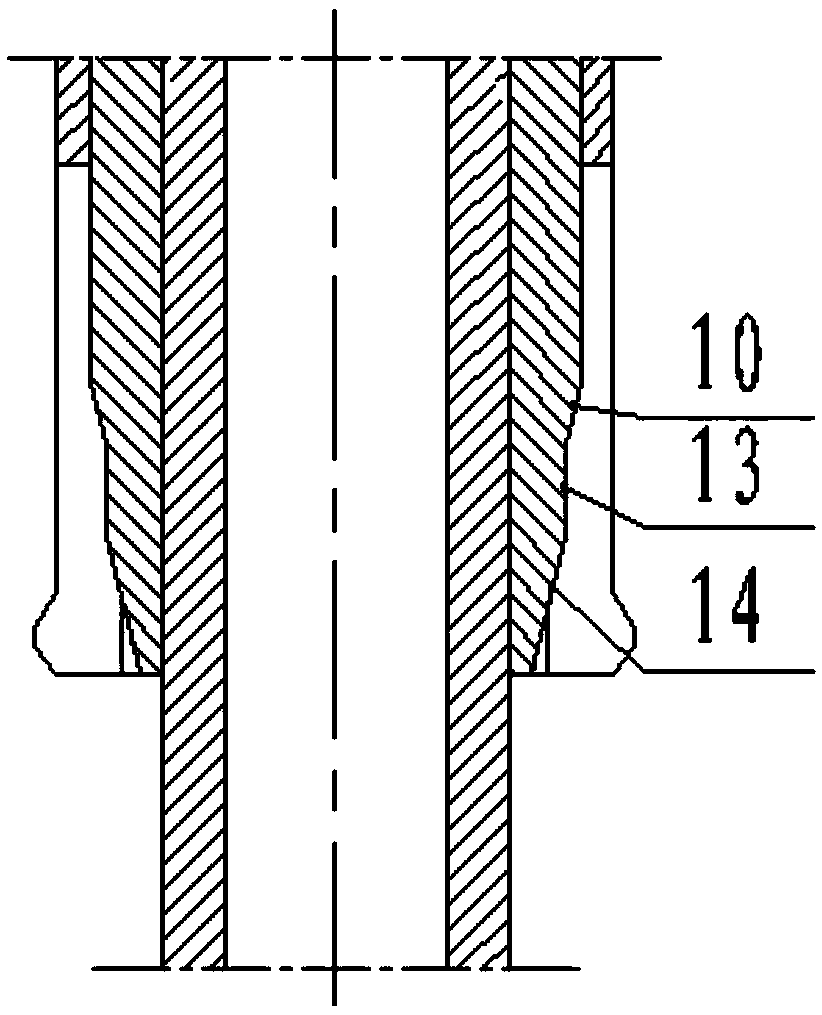

Hydraulic expandable liner hanger provided with double-safety releasing gadget

ActiveCN105781461AInflated in placeEnough expansion forceBorehole/well accessoriesHydraulic cylinderAdaptor/connector

The invention discloses a hydraulic expandable liner hanger provided with a double-safety releasing gadget. The hydraulic expandable liner hanger comprises an expansion base tube, an expansion cone and two hydraulic cylinders, wherein the expansion base tube, the expansion cone and the hydraulic cylinders are mounted on an inner tubing string in a sleeving manner sequentially; a ball socket and a ball assembly re arranged in the top end of the expansion cone, and the upper end of a ball is connected with the lower end of one hydraulic cylinder; a liquid injection hole is formed in the top surface of the hydraulic cylinder at the upper end; the upper end of the inner tubing string is connected with an upper adaptor connector; the lower end of the expansion base tube is connected with a releasing coupling; a collet is mounted in the releasing coupling in a sleeving manner, a releasing body is connected into the upper part of the collet, and the lower end of the inner tubing string is connected into the upper part of the releasing body; an outer slide bushing and an inner slide bushing are mounted inside and outside the inner tubing string respectively in a matched and sleeving manner; a pressure relief hole is formed in one side wall of each of the inner slide bushing, the outer slide bushing and the inner tubing string; a conical pin seat is connected into the lower end of the releasing body; a core tube is arranged in the conical pin seat and the releasing body in a matched manner, the upper end of the core tube is propped against the lower end of the inner slide bushing, and the lower part of the core tube is integrally connected with the conical pin seat through a shear pin; a thrust disc is arranged in the lower end of the collet and connected with the lower end of the core tube.

Owner:XINJIANG YONGSHENG ENERGY CO LTD

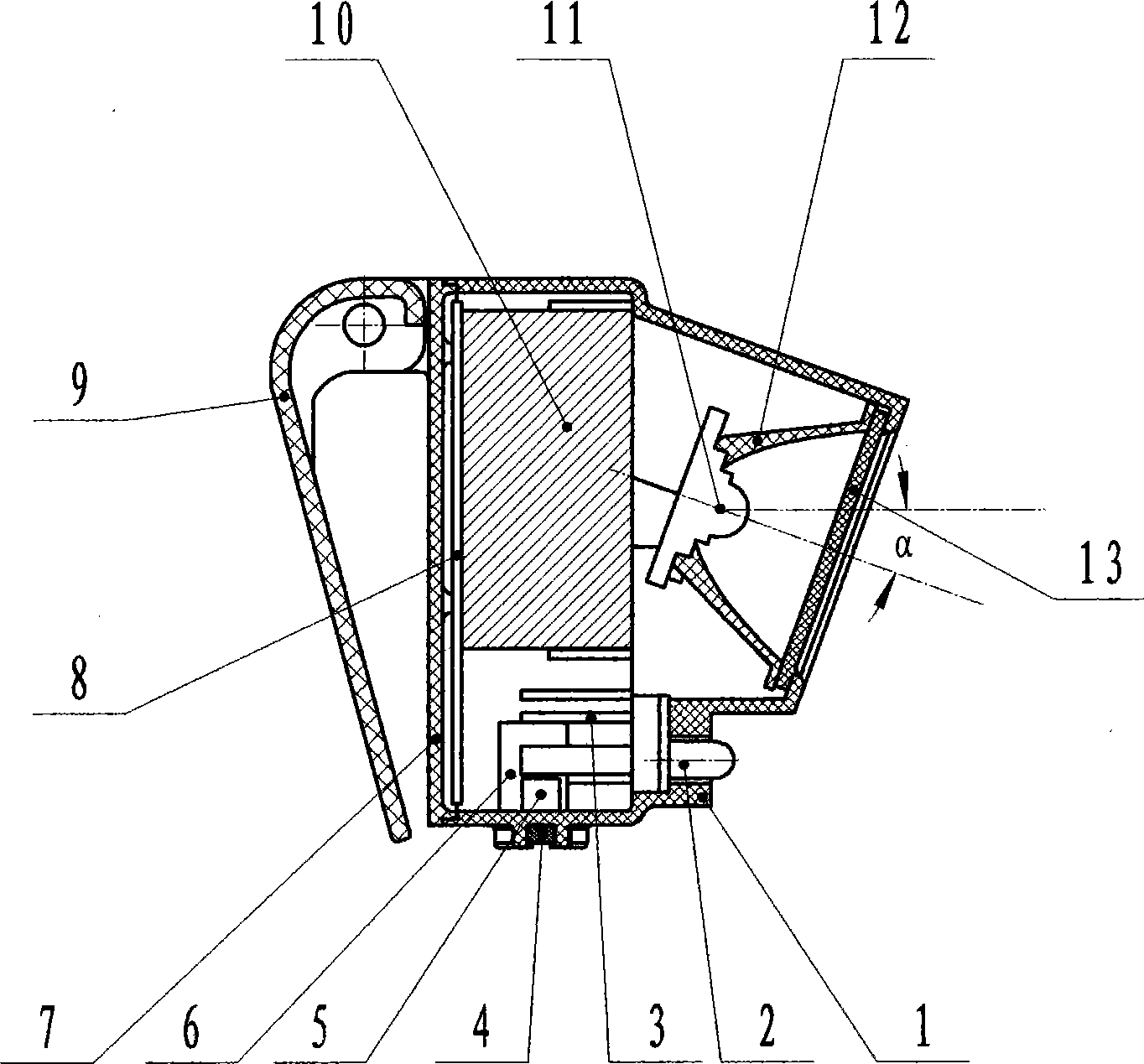

Integrated LED mine lamp

InactiveCN101050845AImprove securityReduce weightLighting applicationsPoint-like light sourceHigh densityEngineering

A unified LED cap-lamp is featured as applying large-power high brightness LED and high density battery set then unifying lamp head and battery case to be an integral unit for eliminating off lamp connection wire existed on traditional miner light.

Owner:XIAN LIMING ELECTRONICS TECH

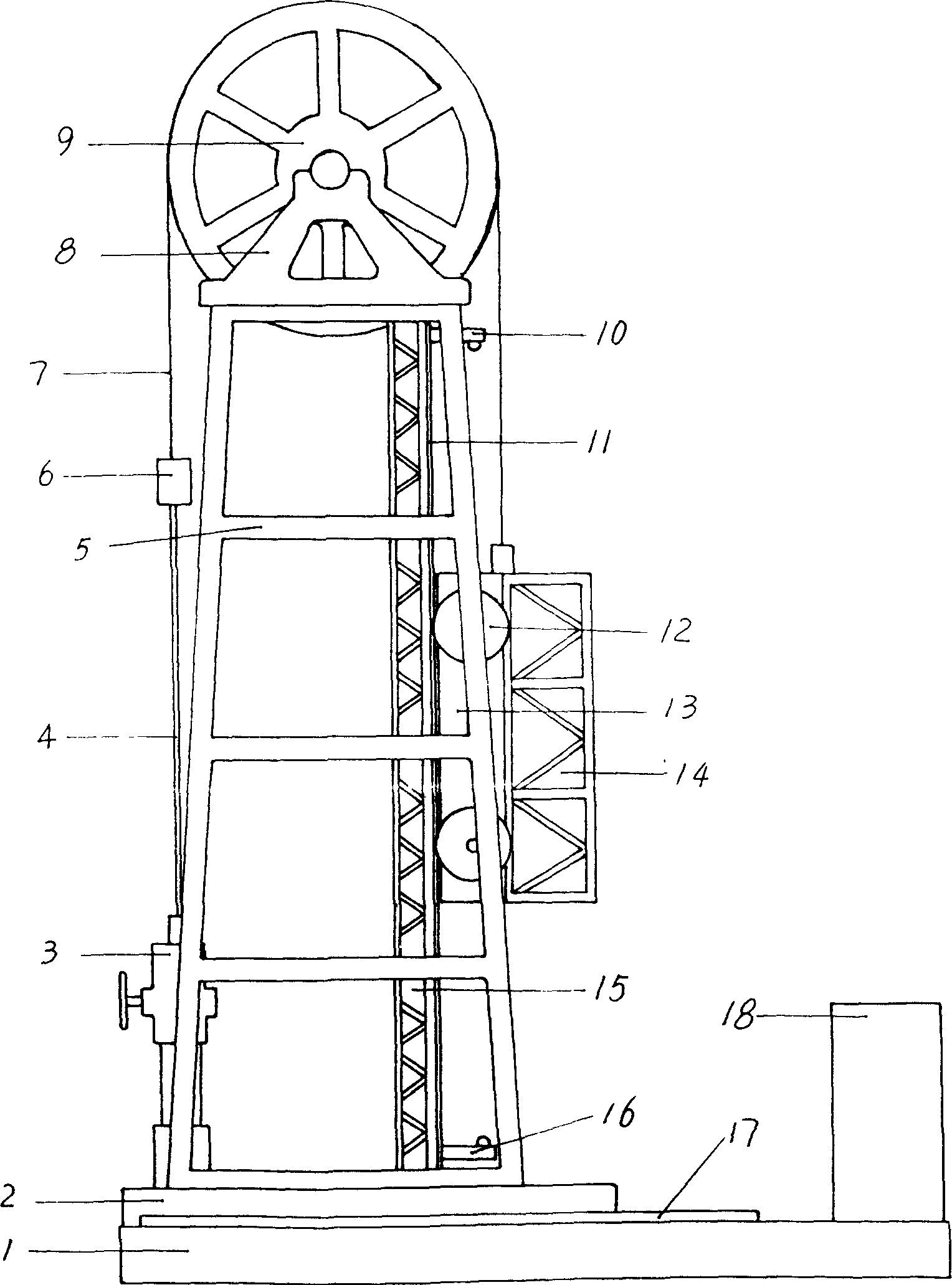

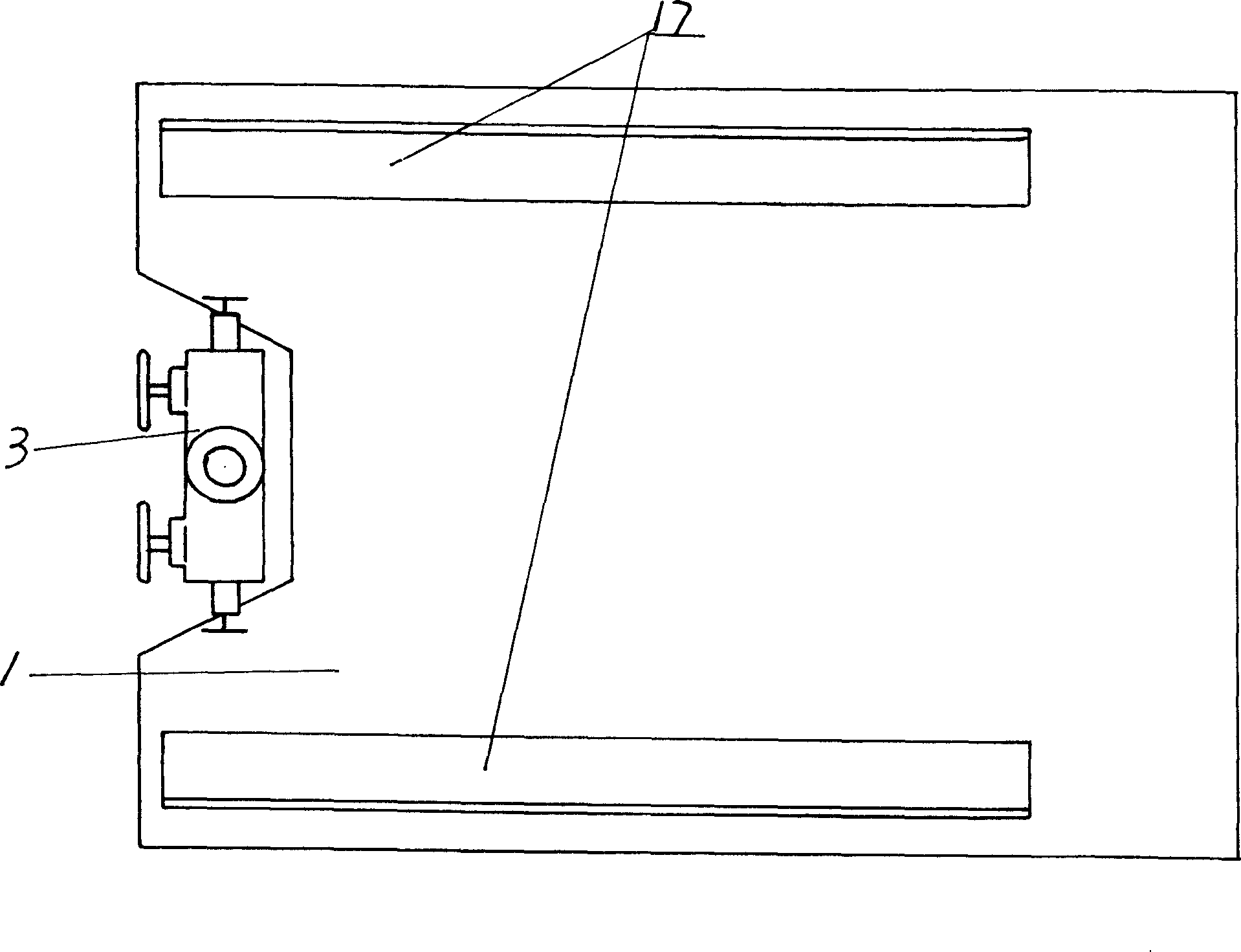

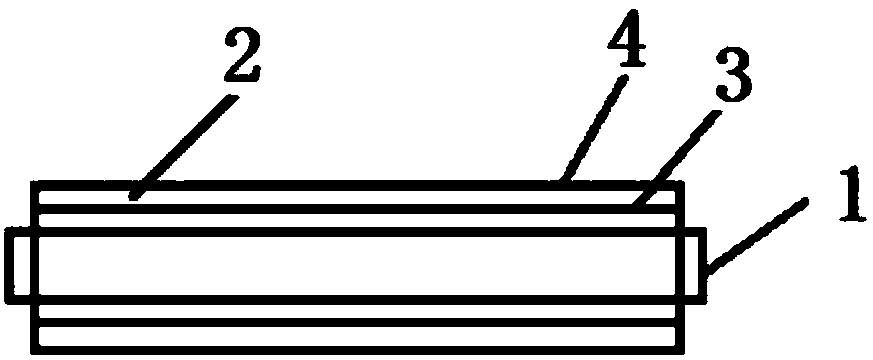

Non walking beam linear motor pumping unit

InactiveCN1525039AEasy to installStable structureFluid removalPropulsion systemsElectric machineLinear motor

The invention provides a beam-free linear electric-machine oil pump, having characters of stable structure, smooth working, high-efficiency energy saving and convenient use and maintenance, applied to oil pumping work in oil field and oil well. Its technical project: it includes main frame, stator fixed on the main frame, rope and rotor linked with the rope, as well as rotor guide rail, rotor guide wheel and spacing commutator, and its character: the stator is a unilateral structure and the rotor adapts to the stator. The rotor is fixed with balance weight box, there is a wind circulating cooling device in the cavity of the rotor, the spacing commutator can movably position, the top end of the main frame is set with head sheave and the main frame can move with the moving base.

Owner:高旺

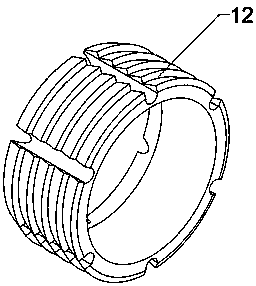

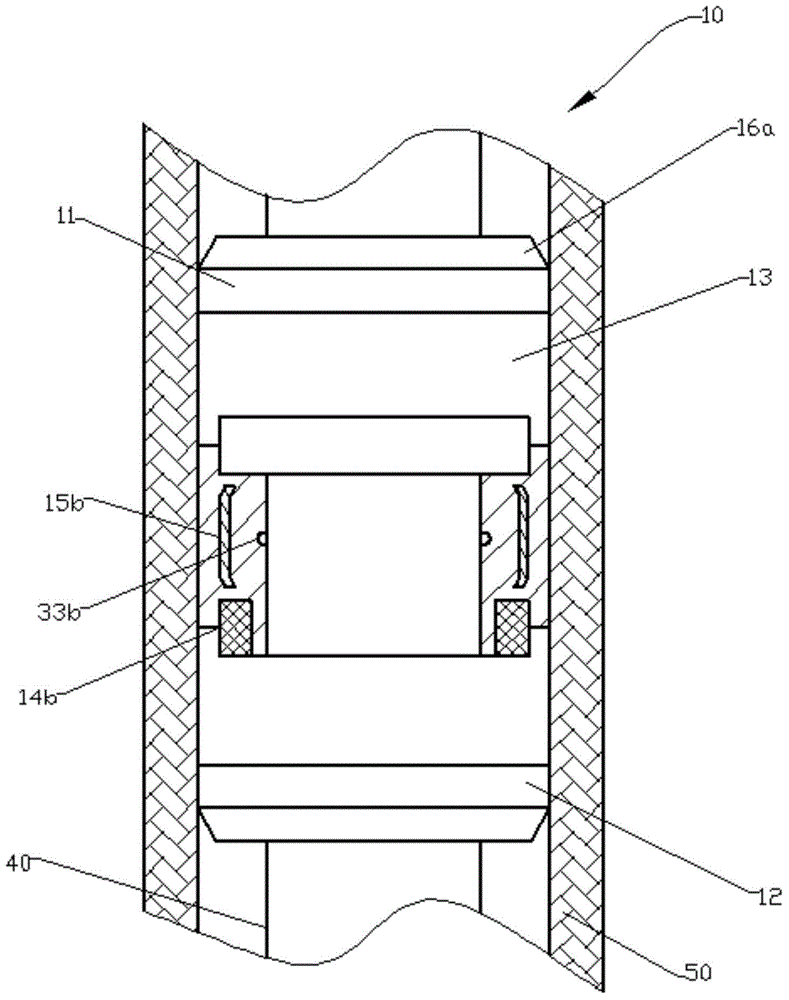

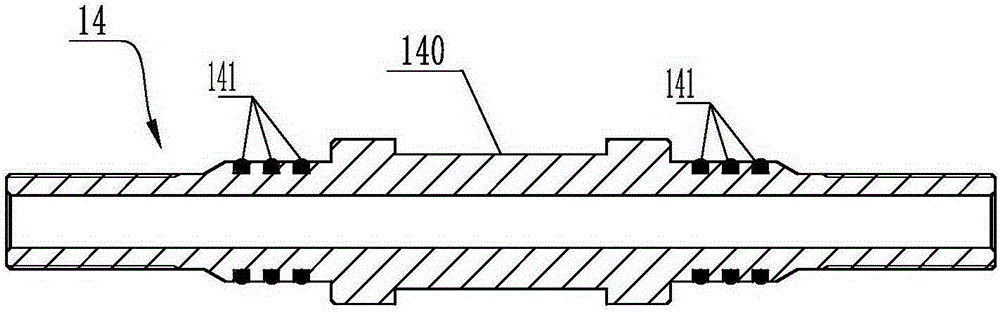

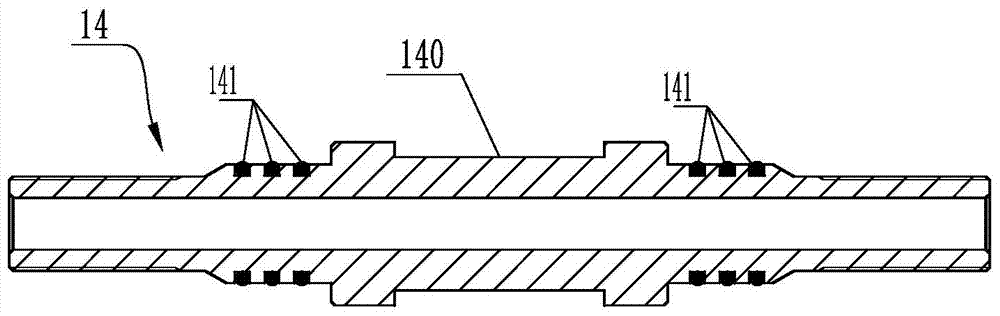

Rubber sleeve for packer and packer

ActiveCN105201445AGood sealing effectThere is no mutual extrusion problemSealing/packingWell drillingPetroleum engineering

The invention relates to a rubber sleeve for a packer and a packer. The rubber sleeve of the packer comprises an elastic sleeve body and rigid support parts wrapping the circumferential side wall of the sleeve body, and multiple separated expansion areas are formed in the sleeve body through the support parts, wherein pressure is exerted to the ends of the sleeve body in the axial direction of the sleeve body, the expansion areas can mutually independently expand outwards in the radial direction. The packer comprises the rubber sleeve for the packer. The rubber sleeve is suitable for operation such as well drilling and well completing, simple in structure, wide in well diameter application range and capable of significantly improving the well entering safety and sealing reliability of tools.

Owner:CHINA PETROLEUM & CHEM CORP +1

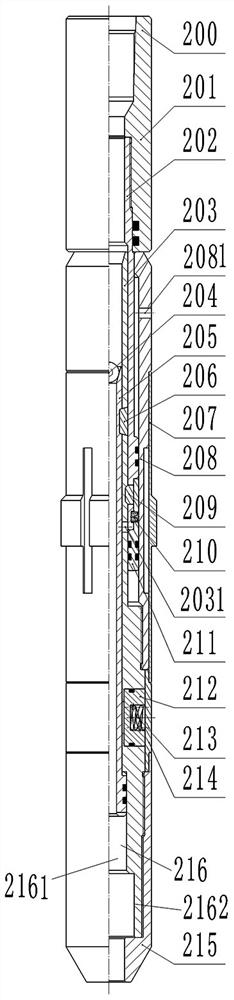

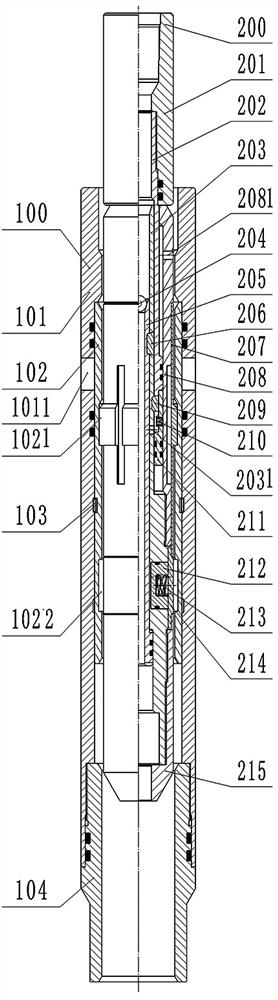

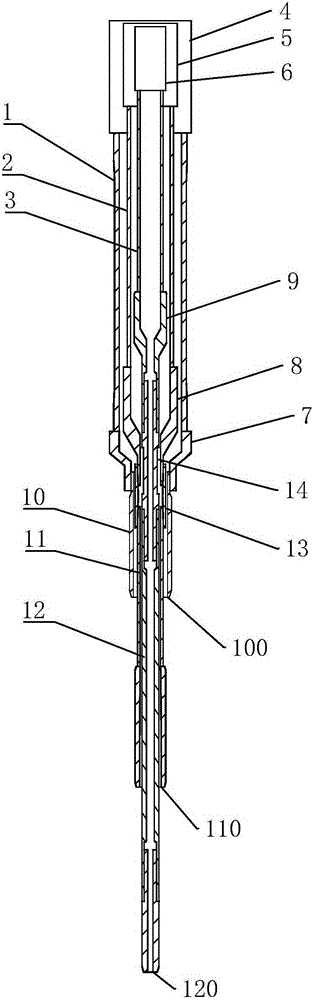

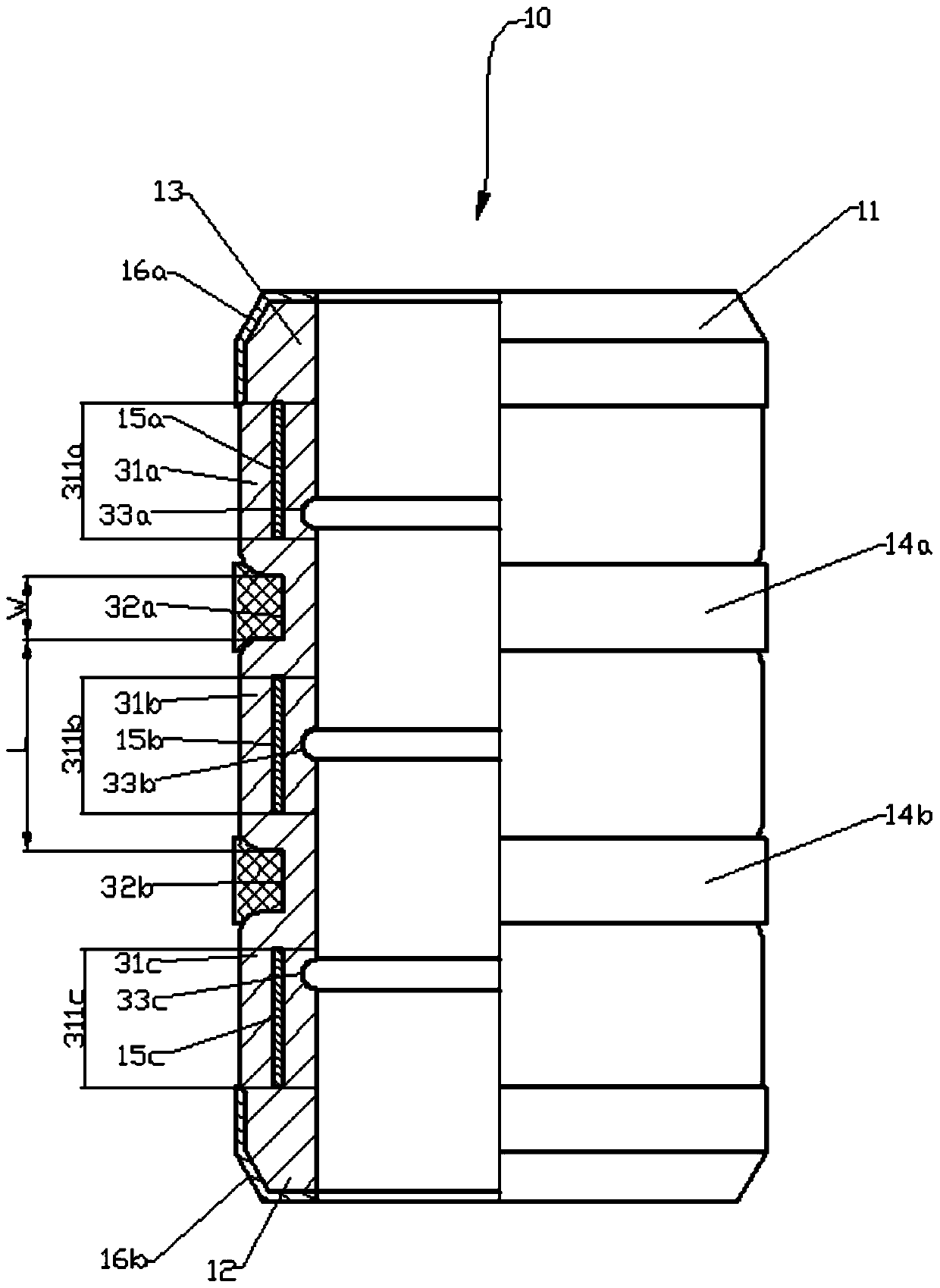

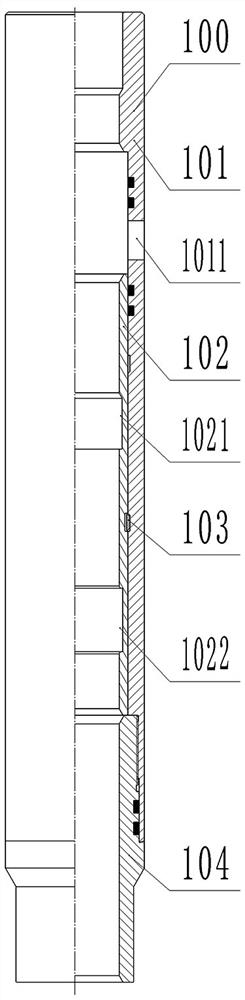

Downhole tubular column and hydraulic opening tool for opening sliding sleeve switch

PendingCN114059963ALow manufacturing costReliable actionWell/borehole valve arrangementsSealing/packingEnvironmental geologyStructural engineering

The invention relates to a downhole tubular column and a hydraulic opening tool for opening a sliding sleeve switch, the upper and lower groove width sizes of annular positioning grooves of all the sliding sleeve switches in the underground pipe column are sequentially increased from top to bottom, and the hydraulic opening tool comprises an inner pipe assembly, a lifting lock tongue, an inward-retracting elastic piece, a positioning boss and an outward-extending elastic piece; an elastic acting force for driving the positioning boss to extend outwards is applied to the positioning boss, the positioning boss has the set up-down width size, and in the process that the hydraulic opening tool is put down through the coiled tubing, when the positioning boss extends outwards to be matched with the annular positioning groove in the corresponding sliding sleeve switch in a positioning and inserting mode, it is indicated that the hydraulic opening tool is lowered in place. In the lowering process, the positioning boss of the hydraulic opening tool is squeezed all the time before the hydraulic opening tool is not lowered in place due to the size problem until the positioning boss is clamped with the annular positioning groove of the selected sliding sleeve switch and the annular positioning groove of the selected sliding sleeve switch, it is indicated that the hydraulic opening tool is lowered in place, and therefore the selected sliding sleeve switch can be accurately turned on, and the turning-on accuracy is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

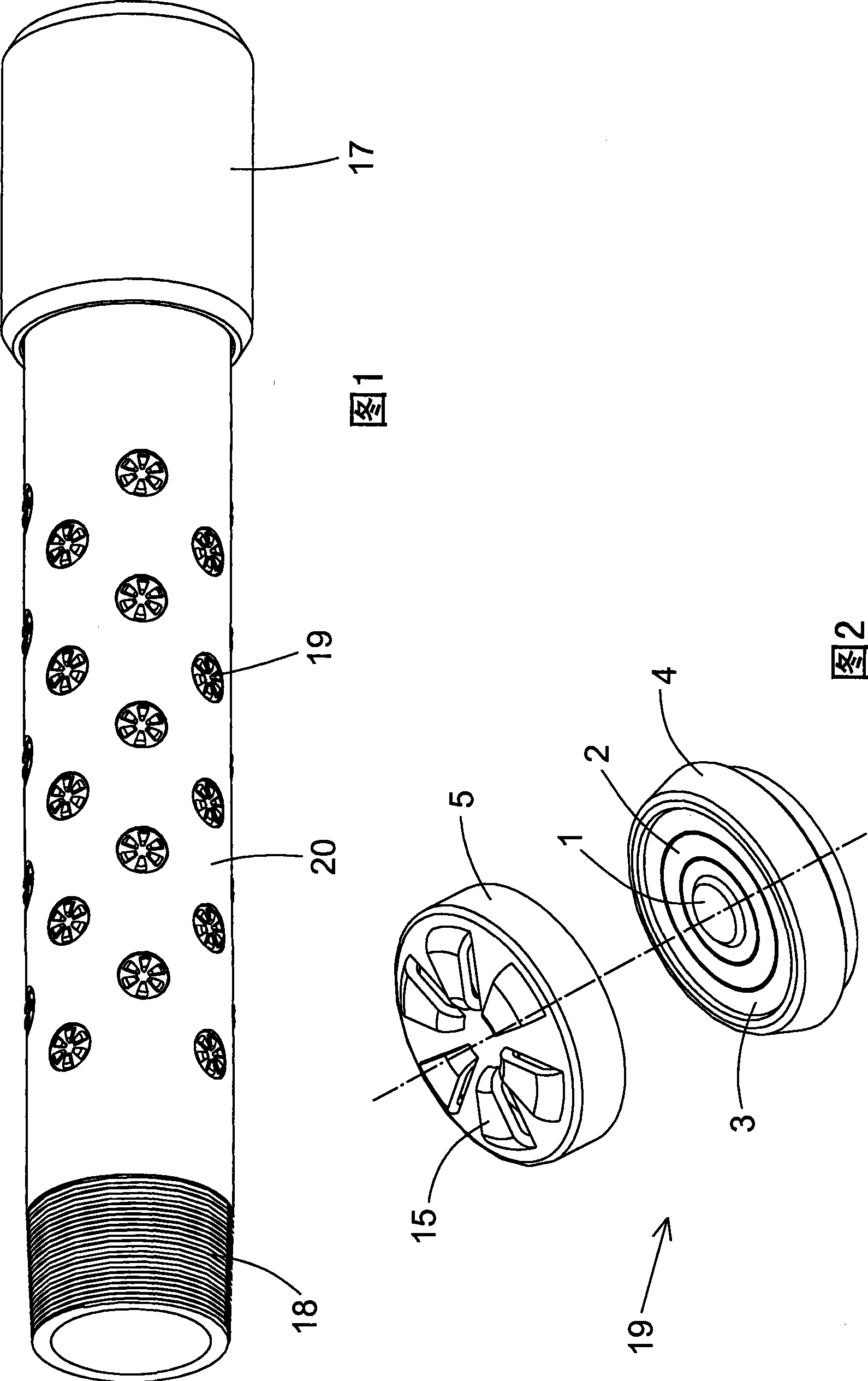

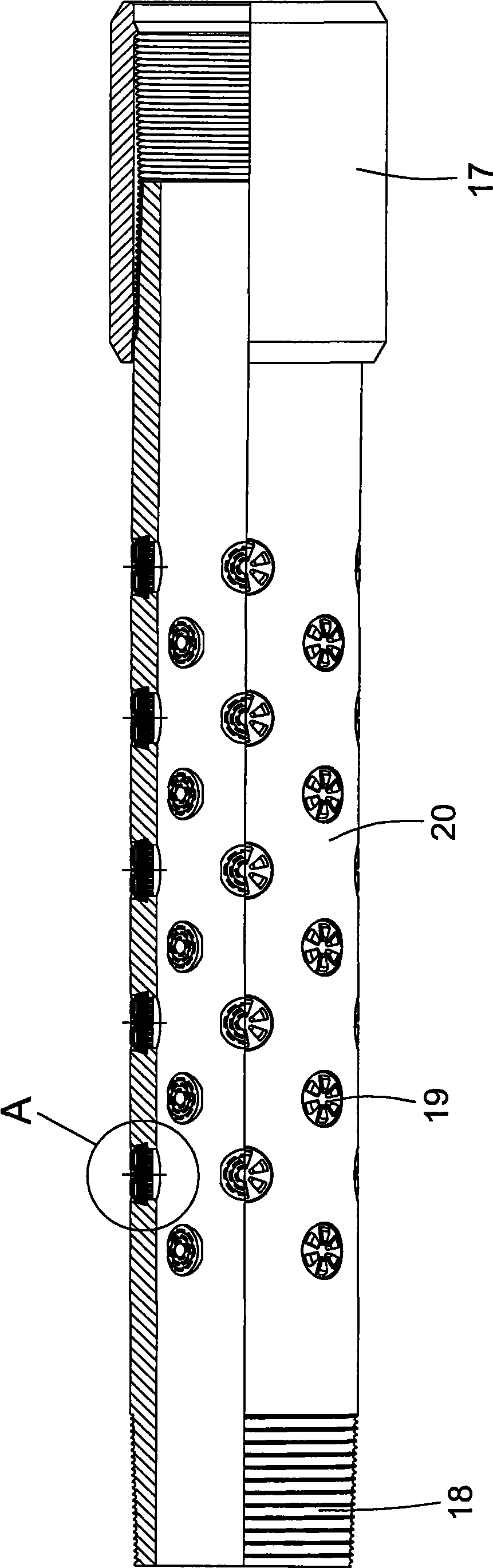

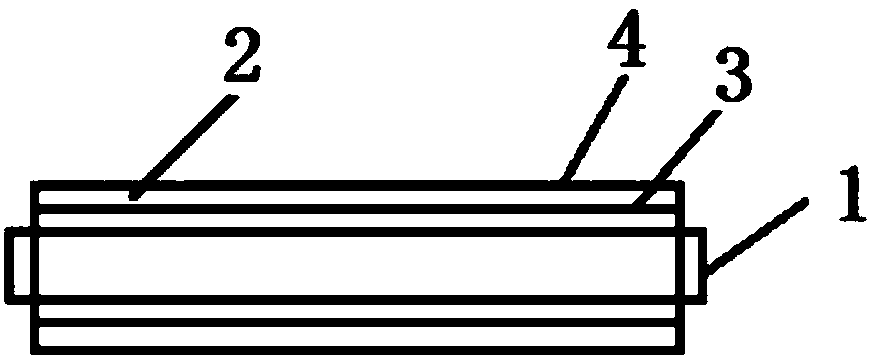

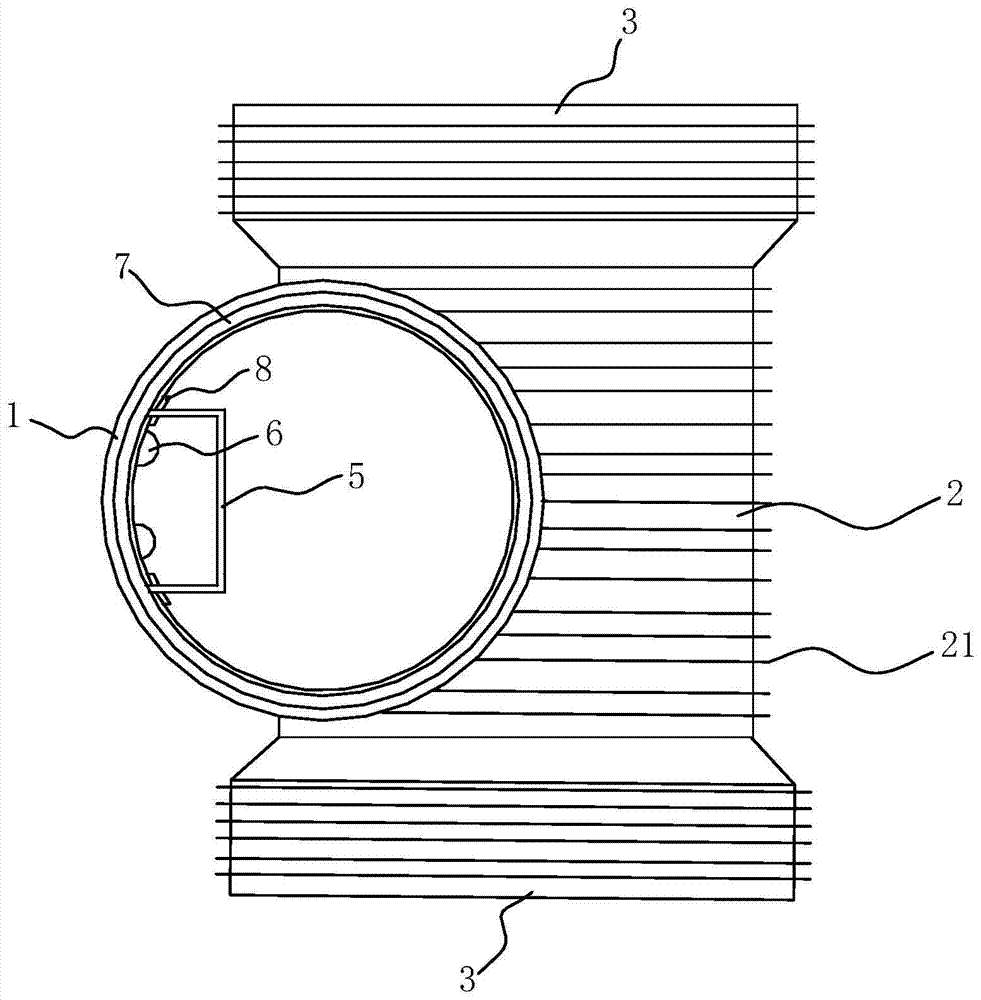

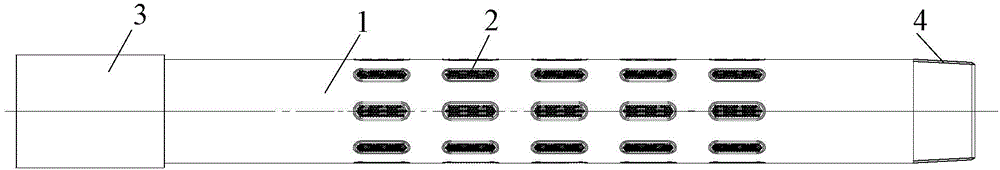

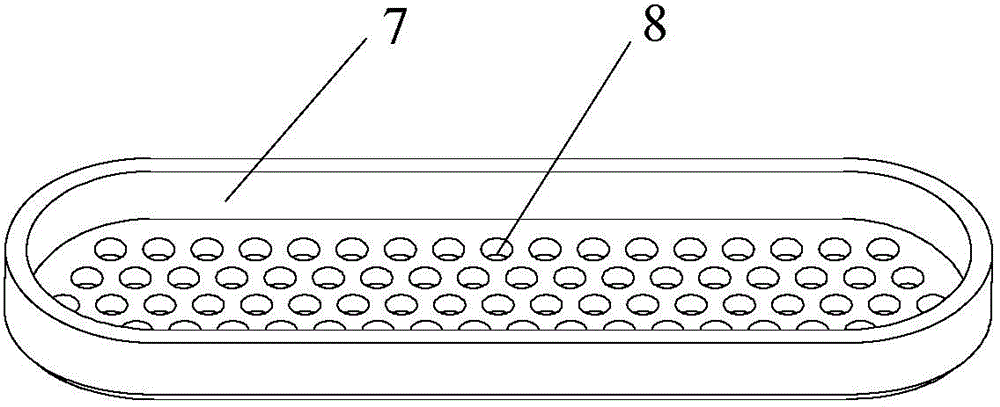

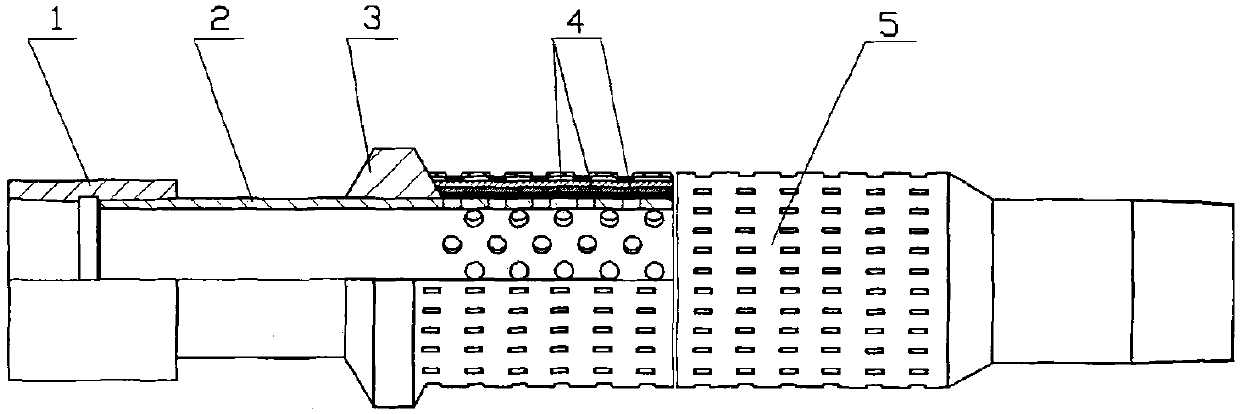

Double-filtering layer meander circular seam self-cleaning sieve tube

The invention discloses a double filtering-layer meandering circumferential weld self-cleaning sieve tube which is composed of a filter element and a basal tube; the filter element is embedded in a stepped hole at the side wall of the basal tube and is composed of a central cap, a plurality of filtering rings, a fixed ring and a protective cover. The size of the inner diameter of the filtering rings are increased one by one and the inner wall of each filtering ring is a double-stair shape, the outer wall of each filtering ring is an inverted double-stair shape. The outer wall of the central cap is an inverted double-stair shape and the central cap are sheathed in the filtering ring with the smallest inner diameter; all the filtering rings are axially sheathed together according to the size order of the inner diameter. The inner wall of the fixed ring is a double-stair shape and the filtering ring with the largest inner diameter is sheathed in the fixed ring; the outer wall of the fixed ring is an inverted double-stair shape and the upper part of the fixed ring is a conical surface and the lower part thereof is a cylindrical surface. The protective cover is covered on the conical surface of the outer wall of the fixed ring, a plurality of air vent windows are opened on the top surface of the protective cover. The double filtering-layer meandering circumferential weld self-cleaning sieve tube can filter the thin-fine sand, the permeability is high, the filter precision is high, and the filtering seam has extremely strong damage-resistance capacity and is not easily to block.

Owner:浙江省星炬科技有限公司

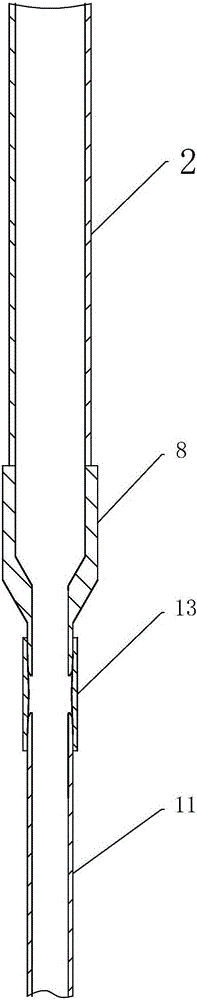

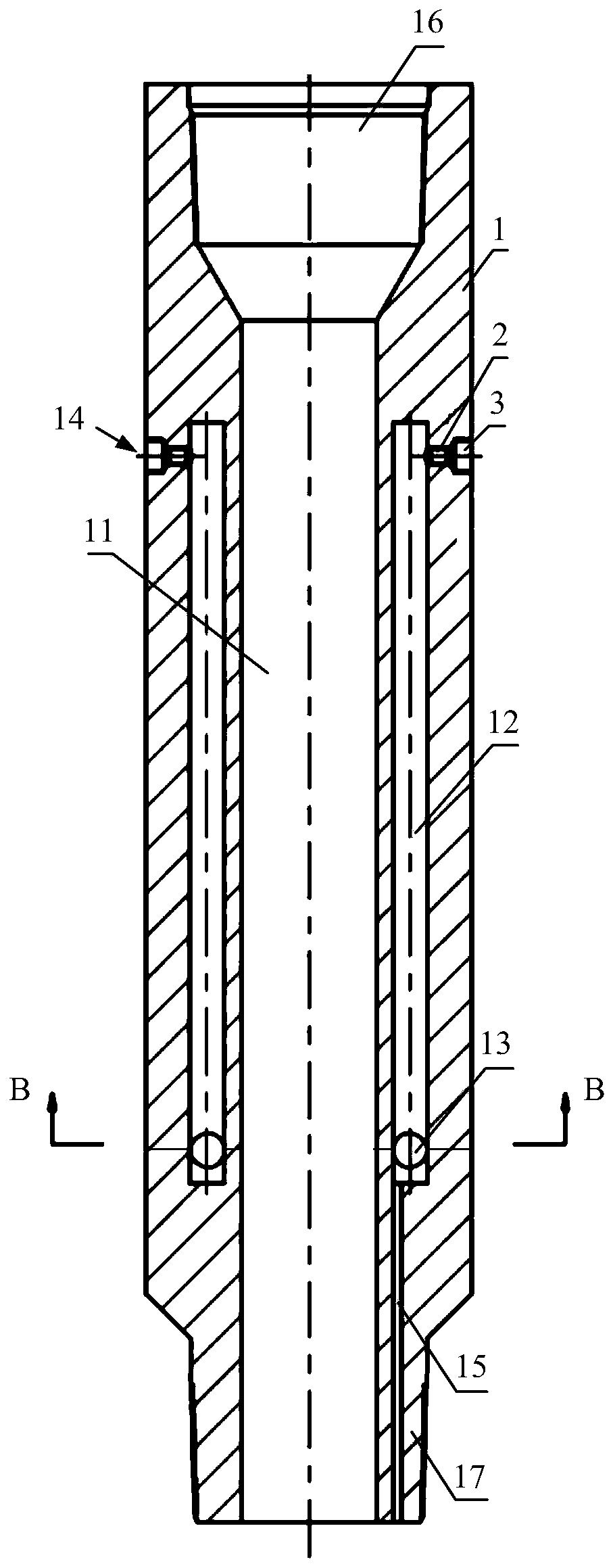

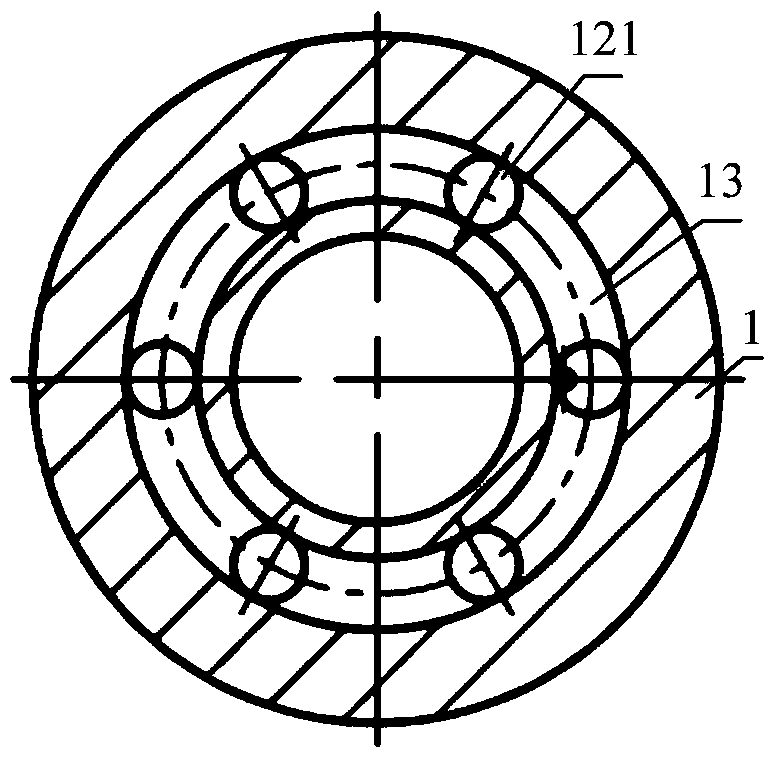

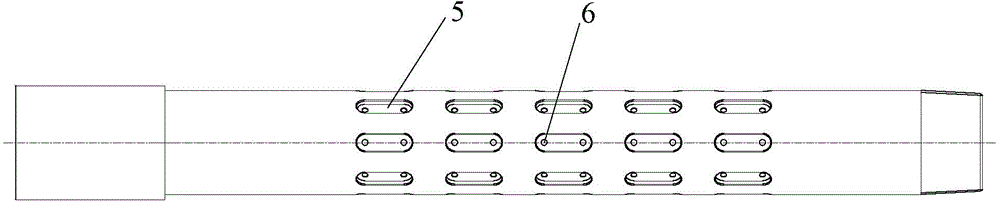

Three-layer tubing string separated injection device

ActiveCN105275411ASolve the water injection methodImprove water injection efficiencyDrilling rodsFluid removalInter layerWater pipe

The invention relates to a three-layer tubing string separated injection device, which comprises an outer-layer tubing string, an intermediate-layer tubing string and an inner-layer tubing string, wherein the three tubing strings are sleeved together. One end of the outer-layer tubing string is provided with an outer-layer connection assembly. One end of the intermediate-layer tubing string is provided with an intermediate-layer connection assembly. One end of the inner-layer tubing string is provided with an inner-layer connection assembly. The other end of the outer-layer tubing string is connected with an outer-layer water-filling pipe via an outer-layer variable-diameter joint. The other end of the intermediate-layer tubing string is connected with an intermediate-layer water-filling pipe via an intermediate-layer variable-diameter joint. The other end of the inner-layer tubing string is connected with an inner-layer water-filling pipe via an inner-layer variable-diameter joint. According to the invention, the separated injection of the oil reservoirs of a three-layer oil well can be realized, so that the water injection efficiency of the oil well is improved. Meanwhile, the device is simple in overall structure, easy to manufacture and install, and very practical.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

Improvement system for severely salinized soil

InactiveCN112723642AImprove efficiencyFacilitated DiffusionSoil lifting machinesSpecific water treatment objectivesSaline waterEnvironmental engineering

The invention belongs to the technical field of soil improvement, particularly relates to an improvement system for severely salinized soil, and provides the following scheme aiming at the technical problems of long prevention and treatment period, low soil improvement efficiency and salt waste caused by incapability of effectively collecting and utilizing salt in soil in an existing vertical shaft drainage mode. The system comprises a solid pipe vertical shaft and a floral pipe vertical shaft, an inner circulation mechanism is arranged at the floral pipe vertical shaft, an outer circulation mechanism is arranged at an upper port of the solid pipe vertical shaft, the outer circulation mechanism comprises a filtering tank, a mixing tank and an evaporating tank which are sequentially connected, and the inner circulation mechanism comprises a water pump. Water in a saline water layer can be pumped into the outer circulation mechanism by the water pump to react, finally generated steam is guided into the floral tube vertical shaft to dilute the saline water layer at the position, and in addition, high-temperature steam heats the water in the saline water layer to accelerate diffusion of saline water in surrounding soil, so that salt in the soil is rapidly separated out, and the soil improvement efficiency is improved.

Owner:郑祥瑞

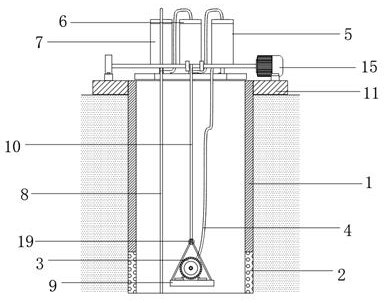

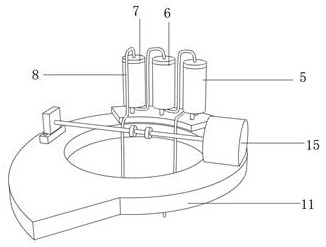

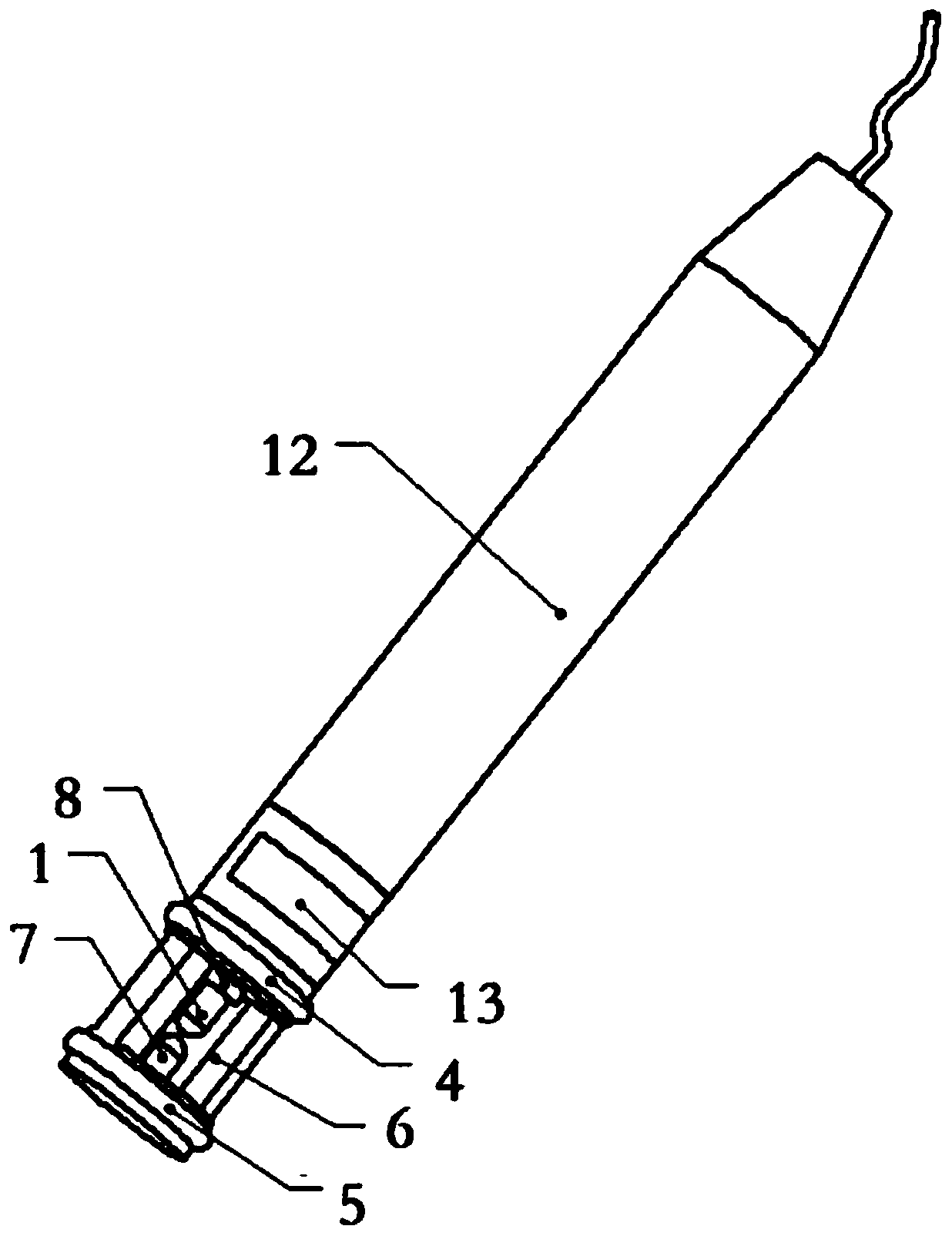

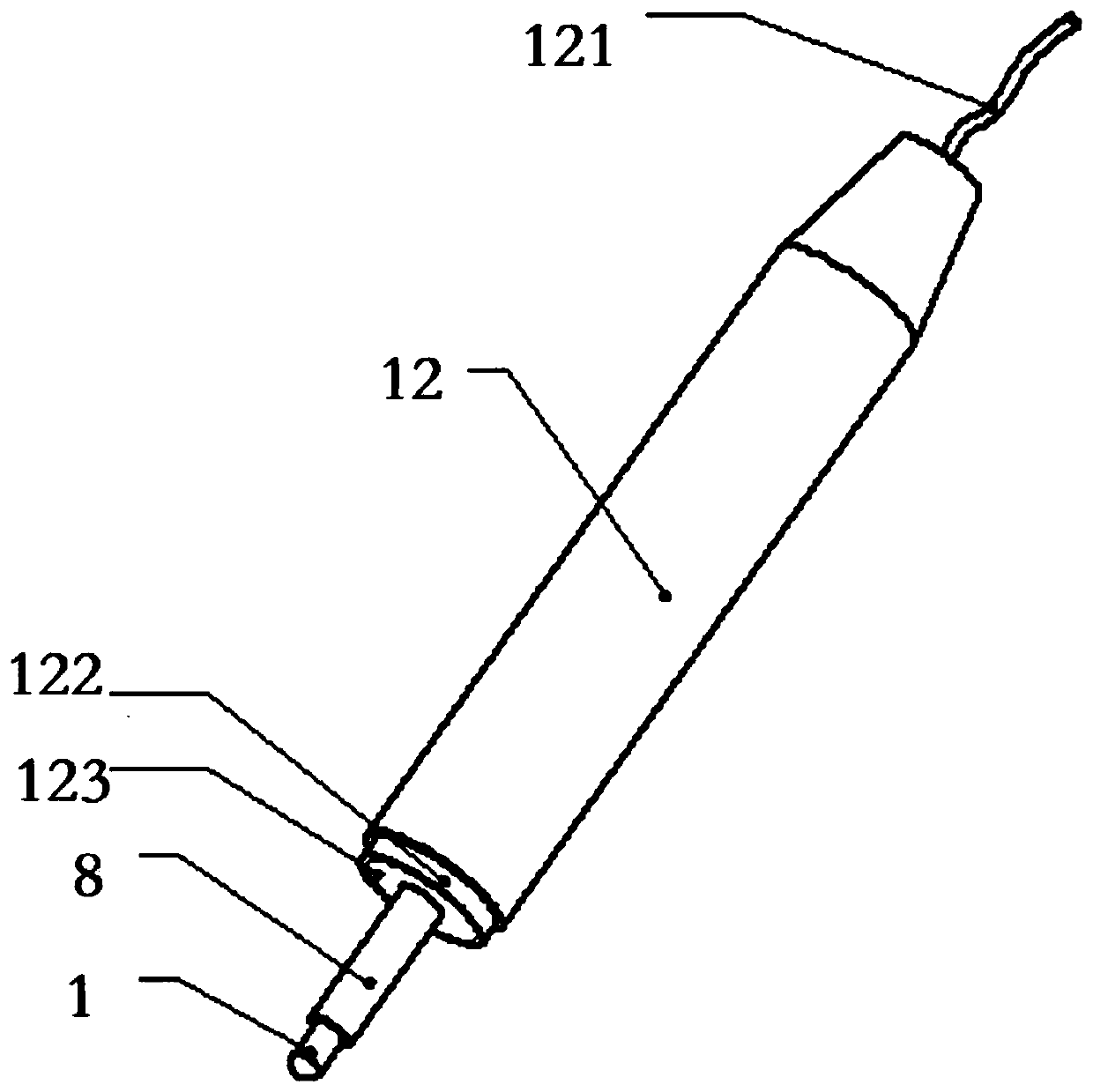

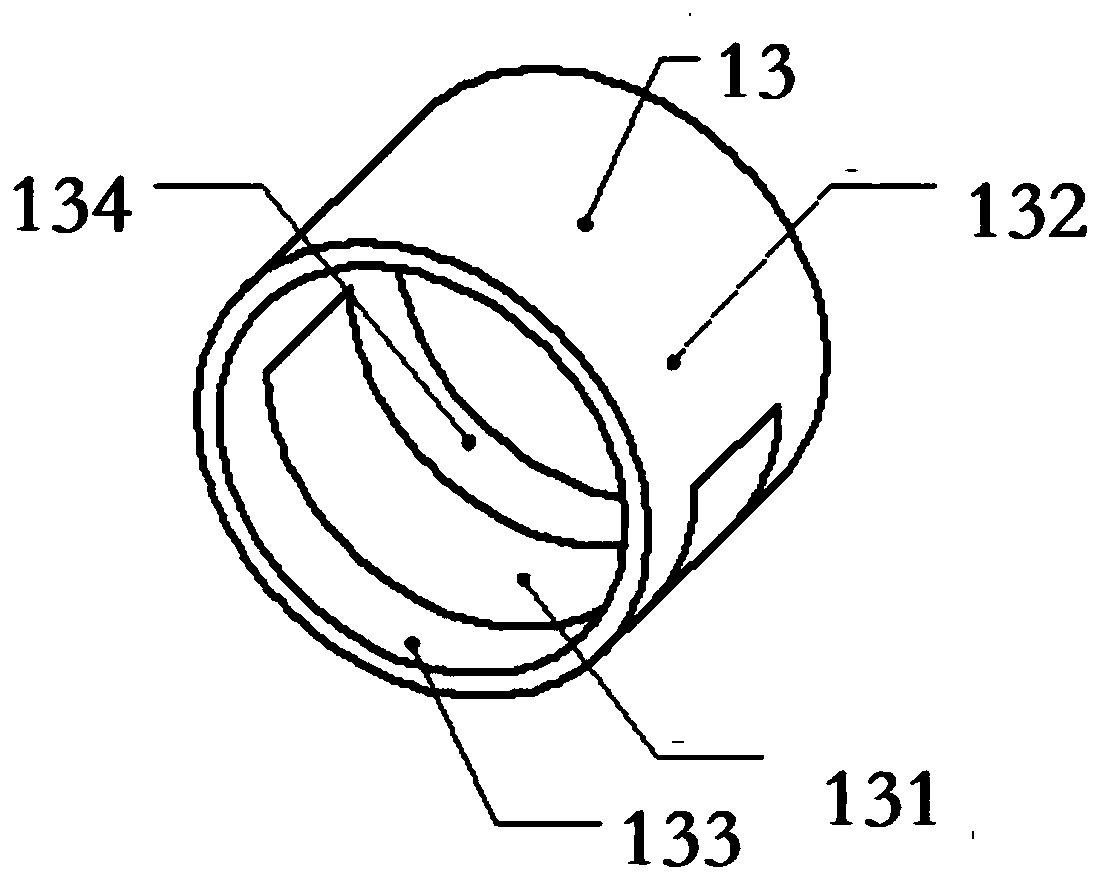

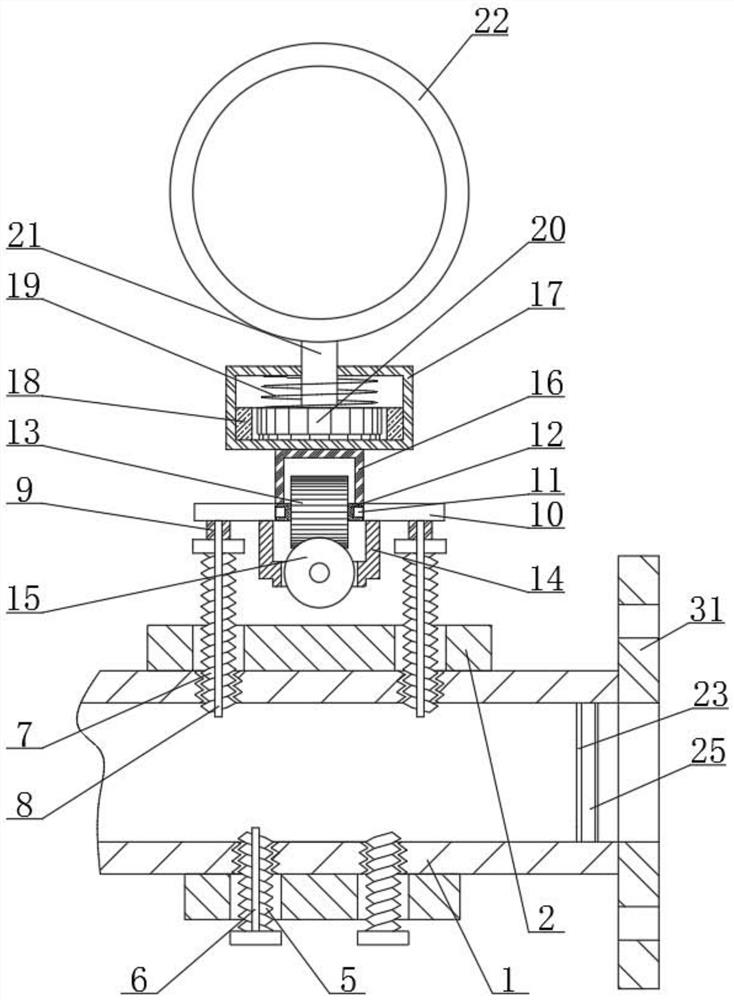

High energy concentration electric pulse plug removal device and operation method

ActiveCN110107272AImprove utilization efficiencyGood plugging effectCleaning apparatusFluid removalHigh energyElectrical impulse

The invention discloses a high energy concentration electric pulse plug removal device. The high energy concentration electric pulse plug removal device comprises an electrode device, a filter sectionand a pulse power supply body; the electrode device comprises an electrode body, a control valve, a first sealing ring, a second sealing ring, a positive electrode and a negative electrode, wherein the control valve, the first sealing ring, the second sealing ring, the positive electrode and the negative electrode are arranged on the electrode body correspondingly; the positive electrode and thenegative electrode are disposed opposite to each other up and down in the electrode body, the first sealing ring and the second sealing ring are correspondingly disposed on the upper side and the lower side of the electrode body, the electrode body is internally provided with a communication hole, the control valve is connected to the communication hole through a short tube, and the first sealingring and the second sealing ring are hollow sealing rings and separately communicate with the communication hole; the positive electrode is connected to the pulse power supply body; and an insulatingring is arranged outside the positive electrode, the filter section is connected to the insulating ring in a sleeved mode, and the filter section is separately connected to the power supply body and the electrode device. The high energy concentration electric pulse plug removal device has a high energy utilization rate, good sealing performance, a compact structure and convenient operation, and isapplicable to the fields of oil well plug removal and production increase and mining of coalbed methane and shale gas.

Owner:南京苏佰能能源科技有限公司

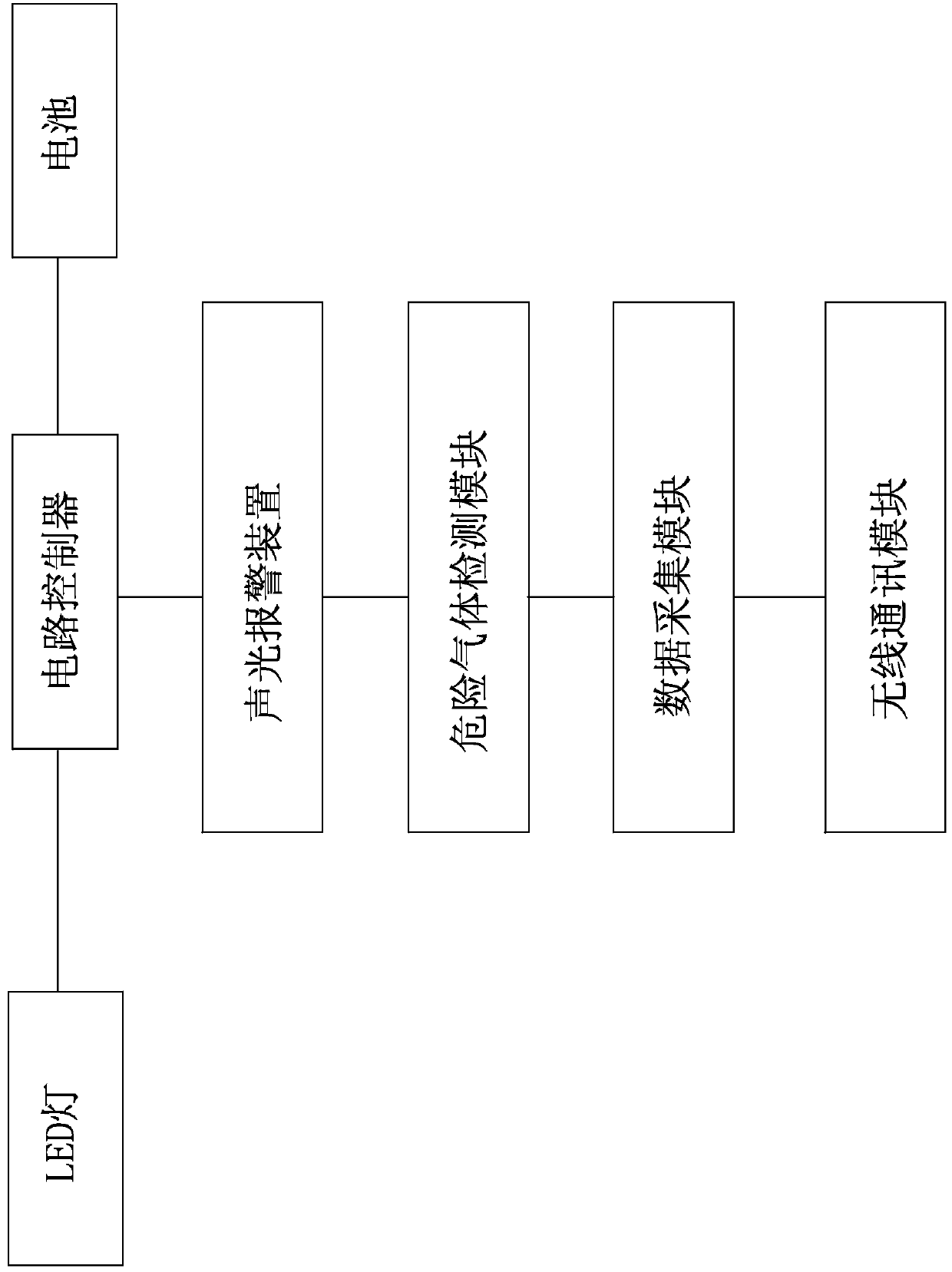

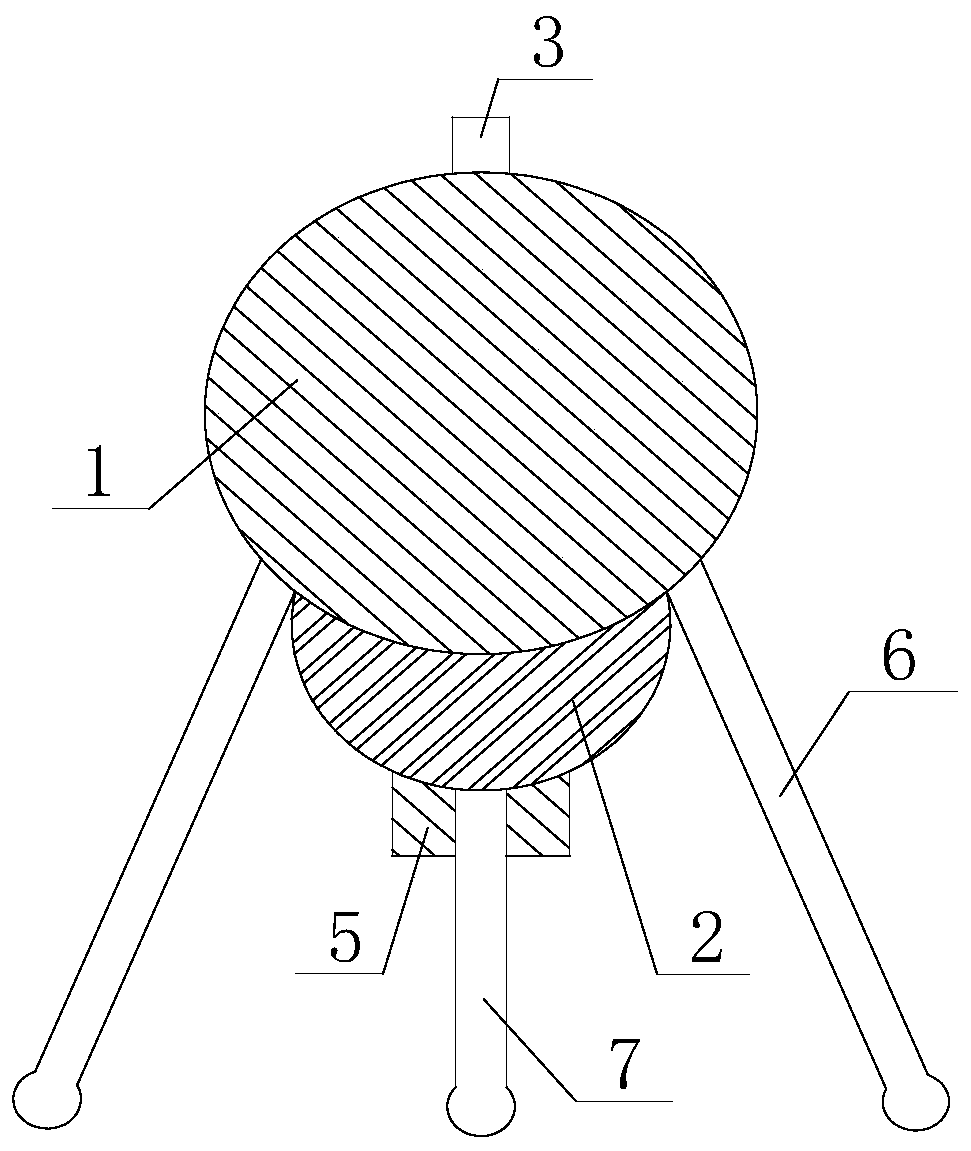

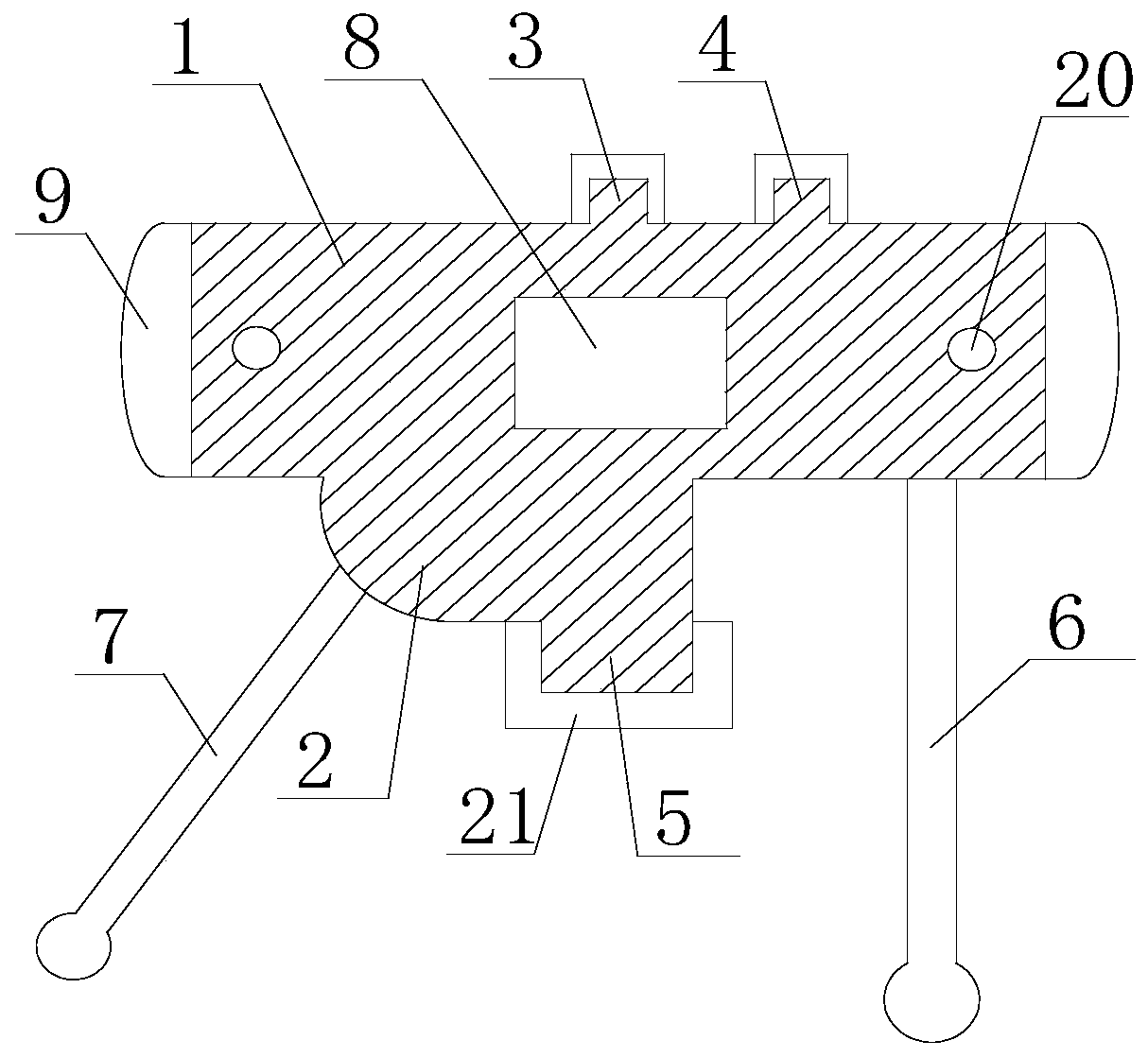

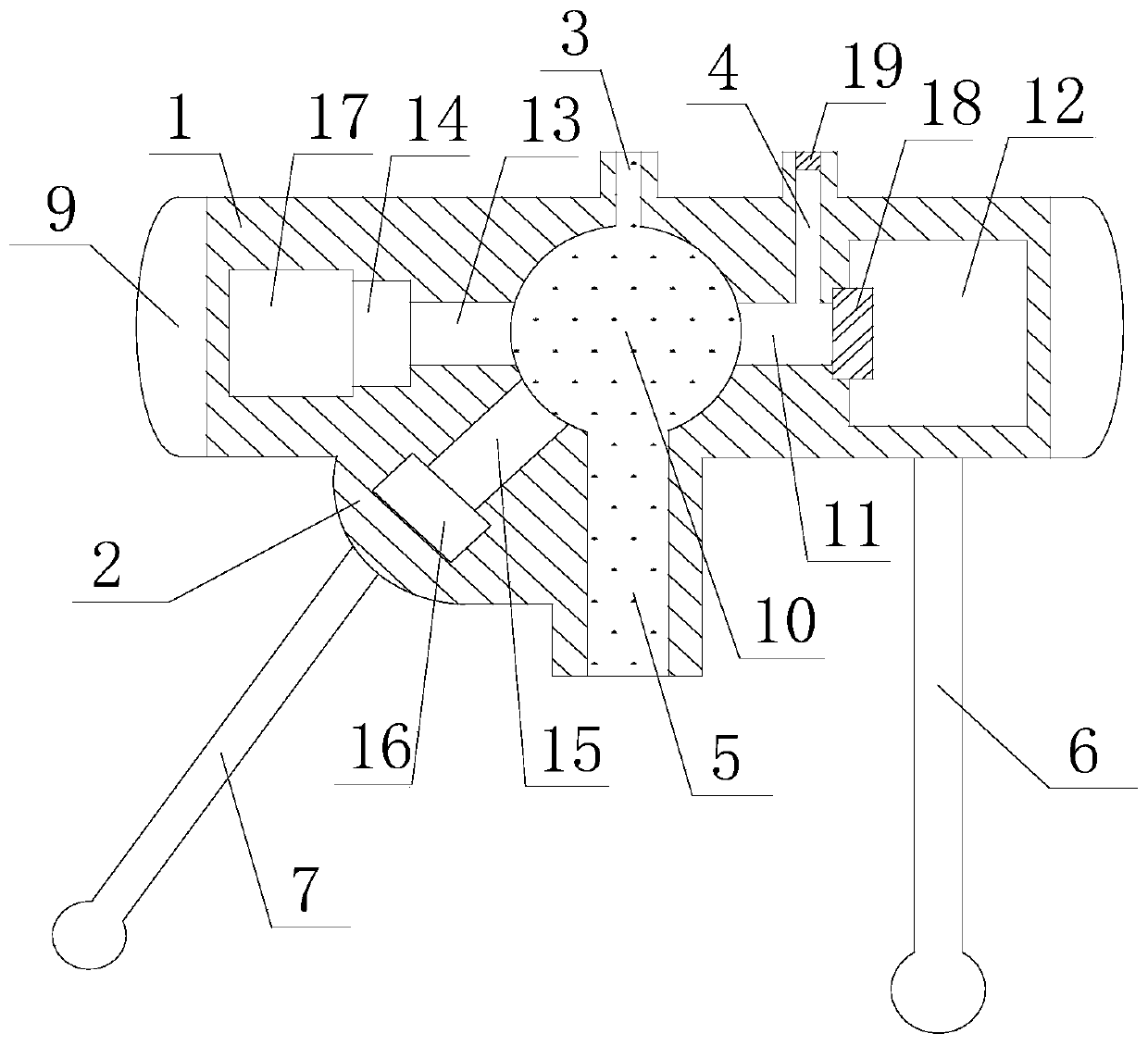

Safety hat

InactiveCN104720178AConvenient downhole operationEasy rescueHatsHeadwear capsComputer moduleEngineering

The invention discloses a safety hat, in particular to a safety hat for mining use, and belongs to the technical field of operational safety protects. The safety hat comprises a body; an LED lamp for lighting use is fixed to the front end of the body. The safety hat is characterized in that a hazardous gas detecting module, a wireless communication module, a circuit controller, a data acquiring module and a battery are arranged on the outside of the body; the top of the body is provided with a sound-light alarm; the LED lamp, a sound-operated alarm, the hazardous gas detecting module and the wireless communication module are connected with the circuit controller; the circuit controller is connected with the battery; the data acquiring module, the hazardous gas detecting module, the wireless communication module and the sound-light alarm are connected in order. The safety hat uses the hazardous gas detecting module, the wireless communication module and the data acquiring module to transmit information data in real time, production safety is enhanced, and safety accidents and casualties are reduced.

Owner:长沙京平泰安防科技有限公司

Dust monitoring device

PendingCN109813642AConvenient dust monitoringHigh measurement accuracyParticle suspension analysisButt jointMonitoring system

The invention discloses a dust monitoring device. The device comprises a dust monitoring main body, an air inlet is formed in the middle of the top of the dust monitoring main body, an air outlet is formed in the middle of the bottom of the dust monitoring main body, an integral arch protrusion and two supporting main frames are arranged at the bottom of the dust monitoring main body, the two supporting main frames are located behind the air outlet, a support sub-frame is arranged at the bottom of the arch protrusion, a dust monitoring system is arranged in the dust monitoring main body and the arch protrusion, an air inlet end of the dust monitoring system is in butt joint with the air inlet, an air outlet end of the dust monitoring system is in butt joint with the air outlet, and a display screen is connected with the dust monitoring system and used for displaying monitoring data of the dust monitoring system. In application, dust monitoring can be conducted in the complex environment under a mine, and meanwhile the measurement accuracy of dust under the mine can be effectively improved.

Owner:CHONGQING VOCATIONAL INST OF ENG

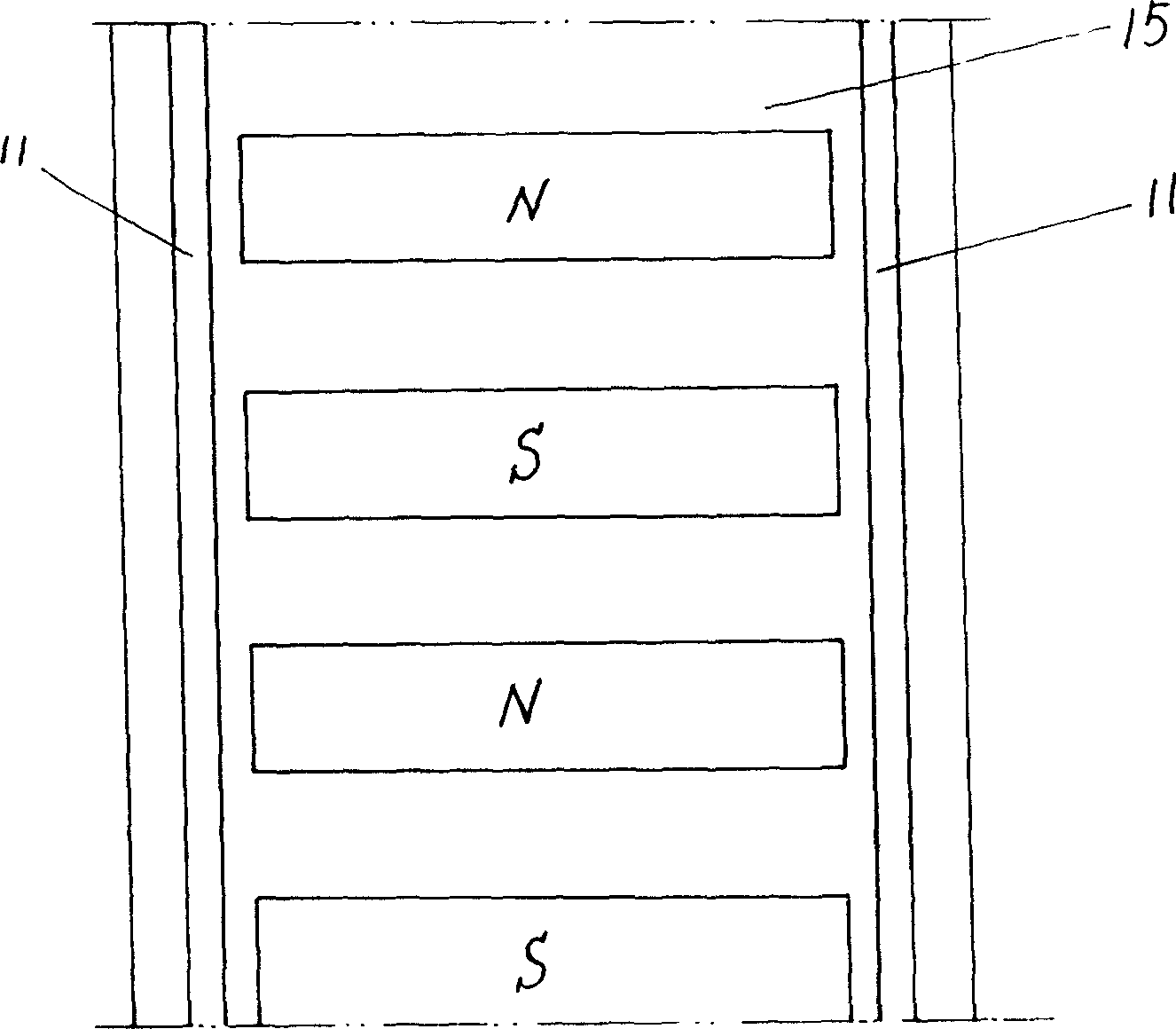

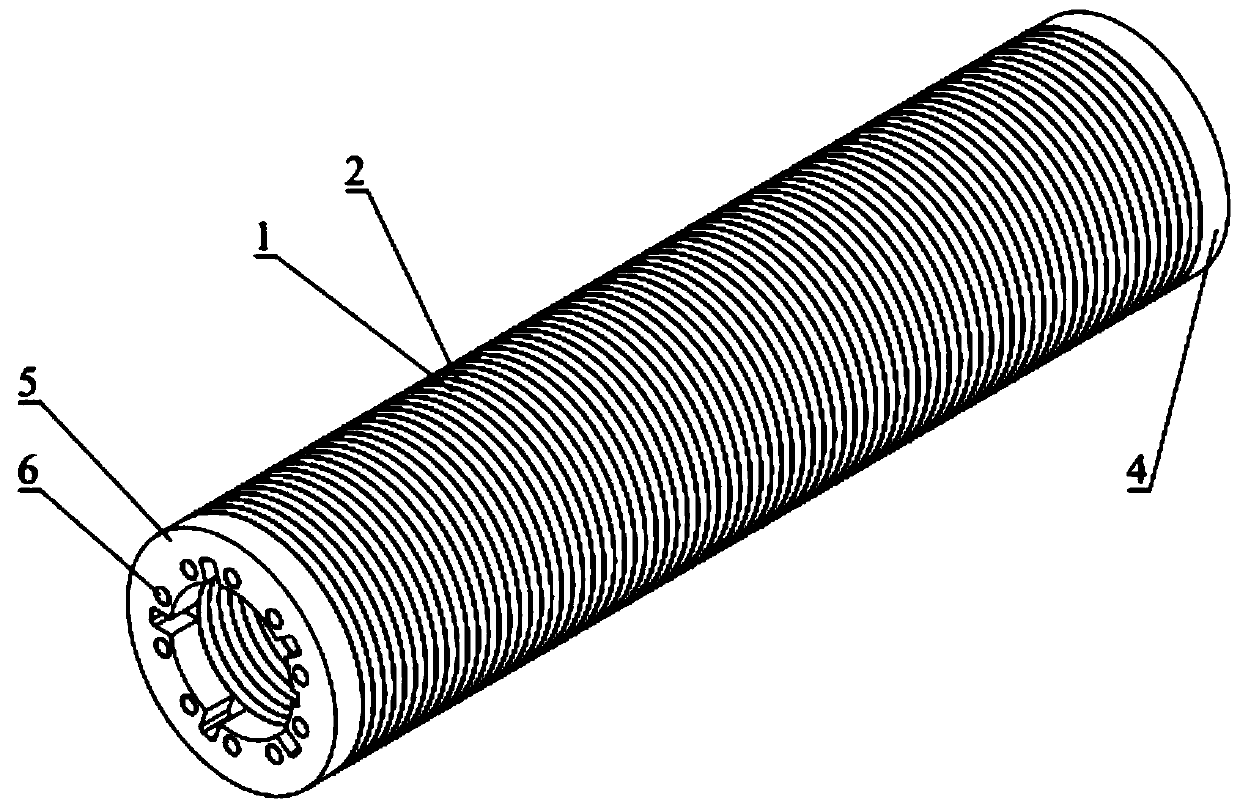

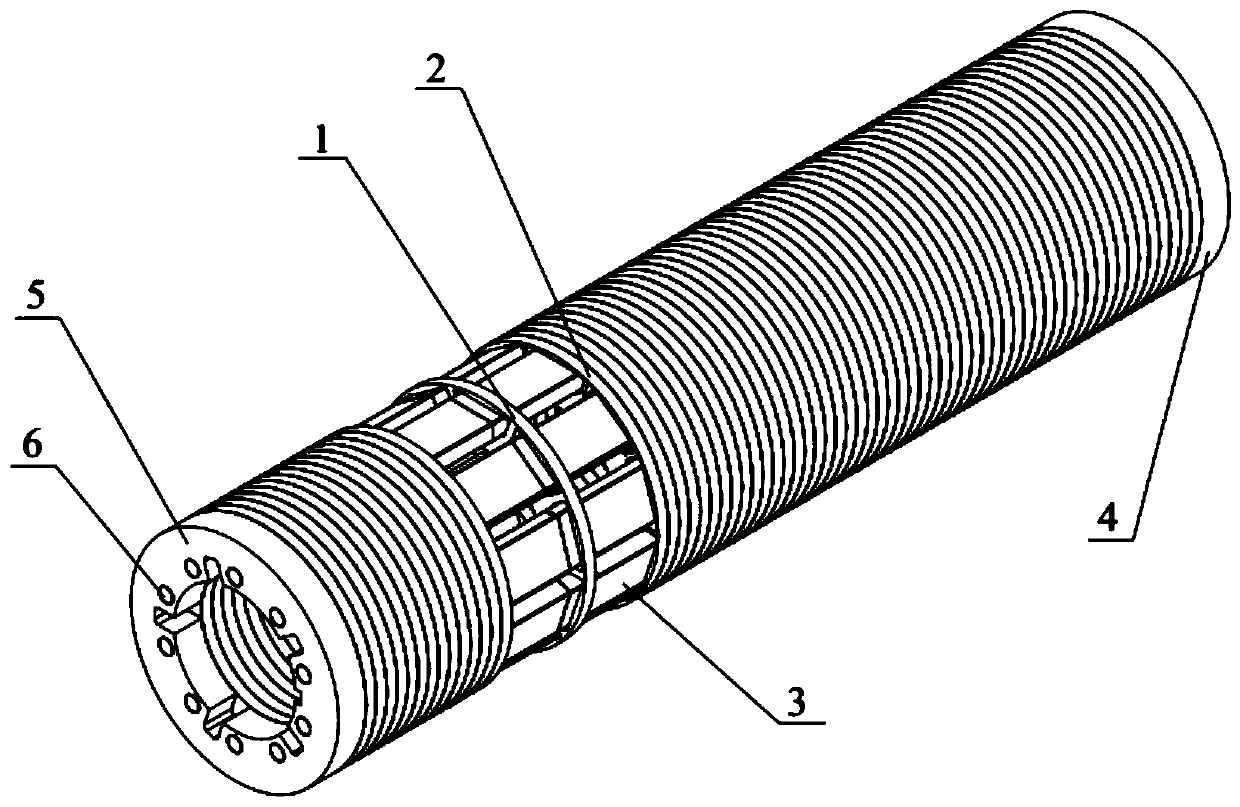

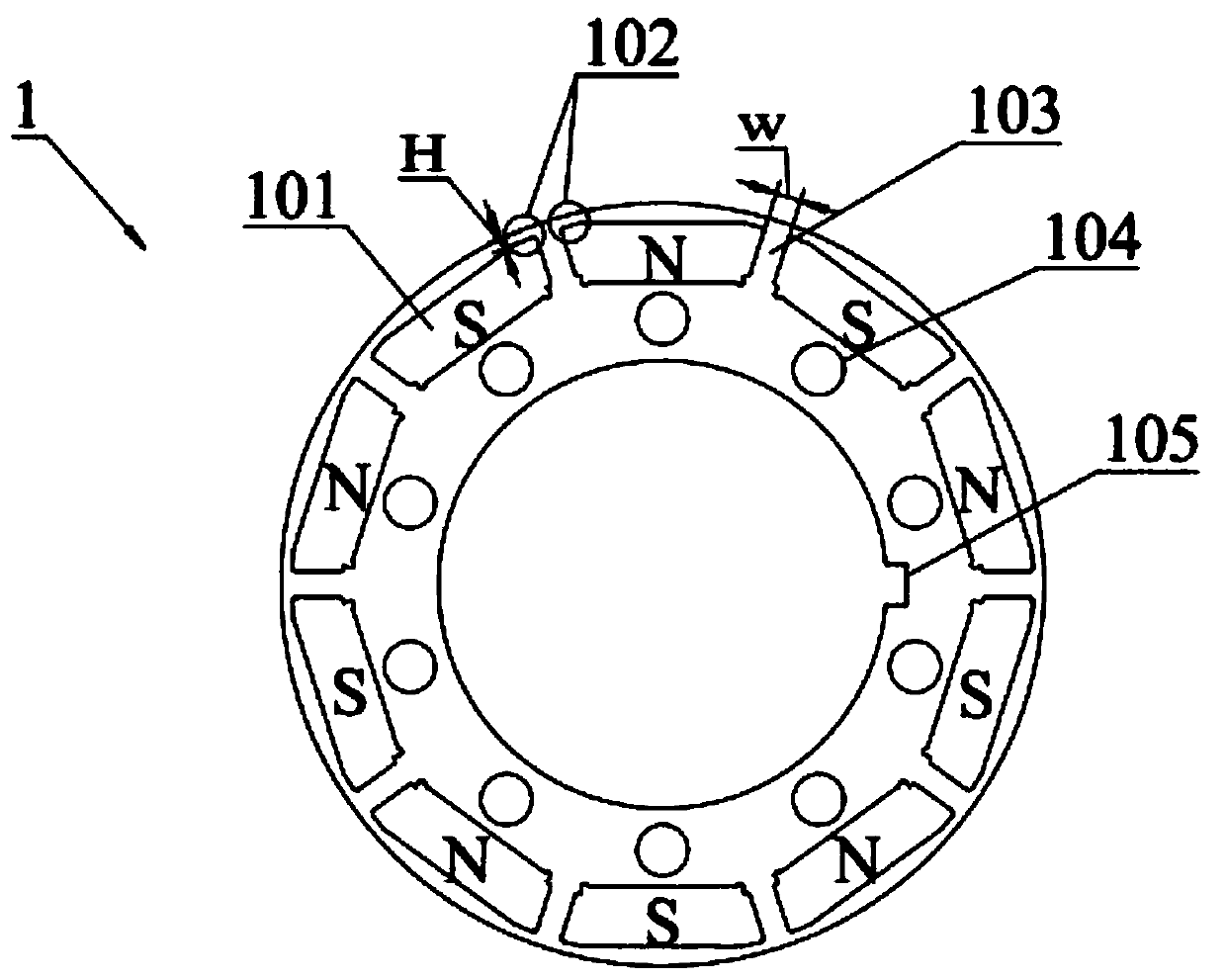

Submersible permanent magnet motor unit rotor with combined punching sheets

PendingCN111416454AReduce Flux LeakageImprove power densityMagnetic circuit rotating partsManufacturing stator/rotor bodiesPunchingElectric machine

The utility model discloses a submersible permanent magnet motor unit rotor with combined punching sheets. The unit rotor comprises high-strength iron core punching sheets, low-leakage magnetic core punching sheets, permanent magnets, an end plate A, an end plate B and a locking rod, the high-strength iron core punching sheets and the low-leakage magnetic iron core punching sheets are arranged inan alternate and laminated mode. Permanent magnets are placed in the permanent magnet grooves of the high-strength iron core punching sheet and the low-leakage magnetic core punching sheet; an end plate A and an end plate B are placed on two sides of a structure formed by alternately laminating the high-strength iron core punching sheets and the low-leakage magnetic core punching sheets; the high-strength iron core punching sheet, the low-leakage magnetic iron core punching sheet, the end plate A and the end plate B are fastened together to form a unit rotor. Compared with a traditional submersible motor unit rotor, the motor has the advantages of being low in magnetic flux leakage and high in power density; under the constraint condition of the same outer diameter and power, the length isshortened by about 20%, and the downhole operation of an electric submersible pump unit (provided with the motor) is facilitated.

Owner:SHENYANG POLYTECHNIC UNIV

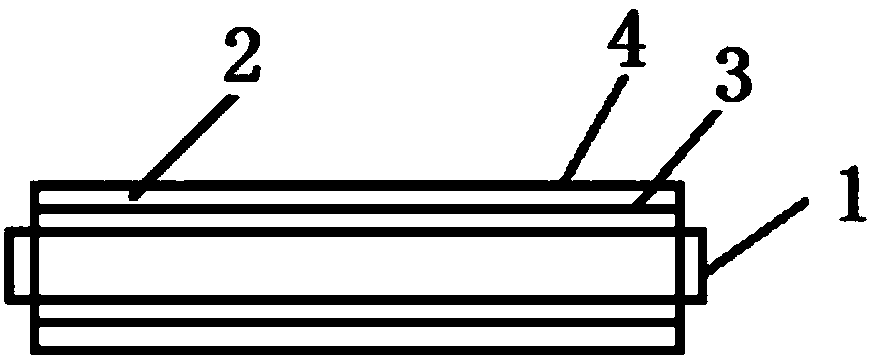

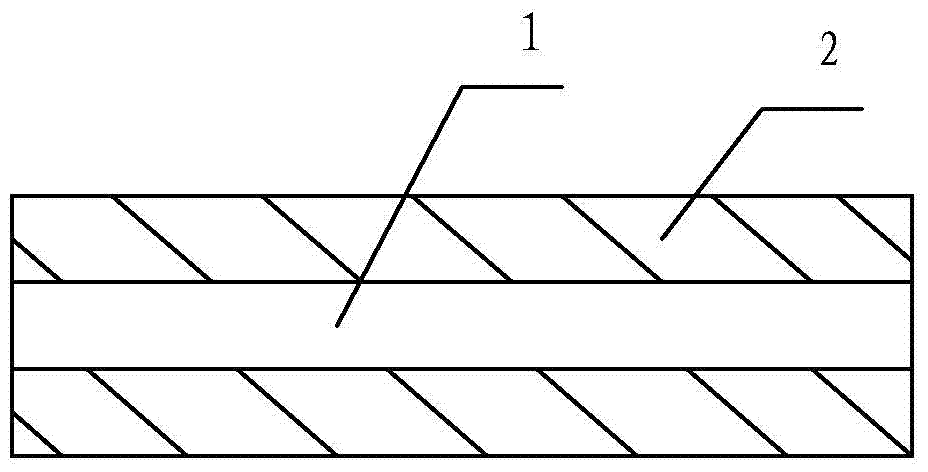

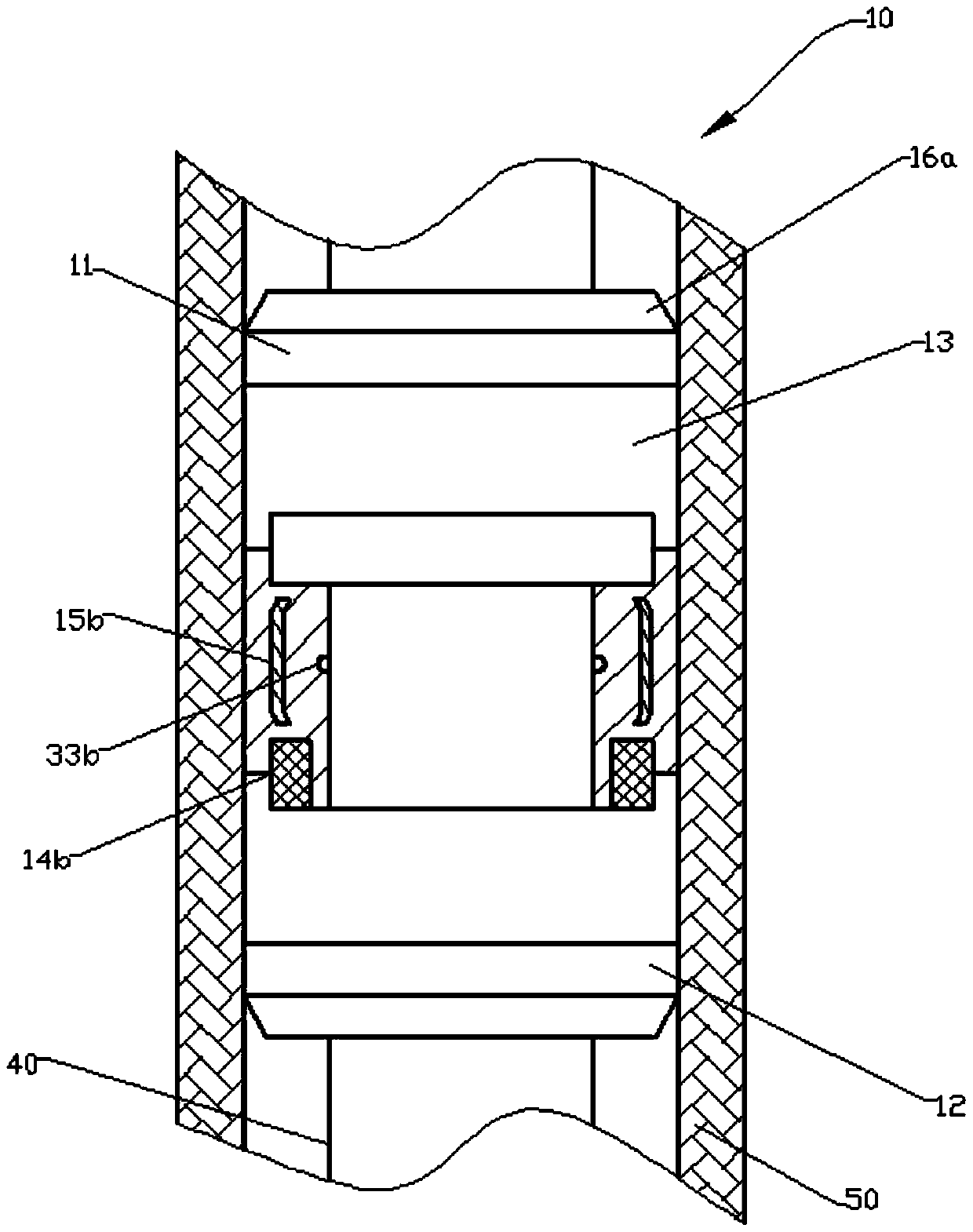

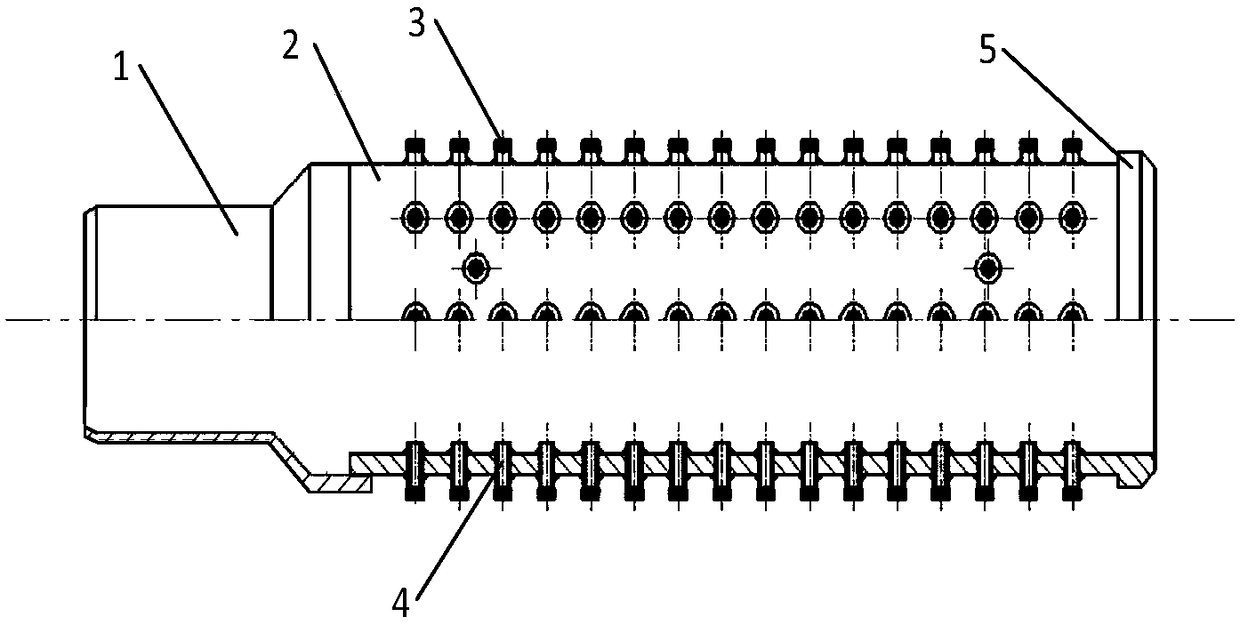

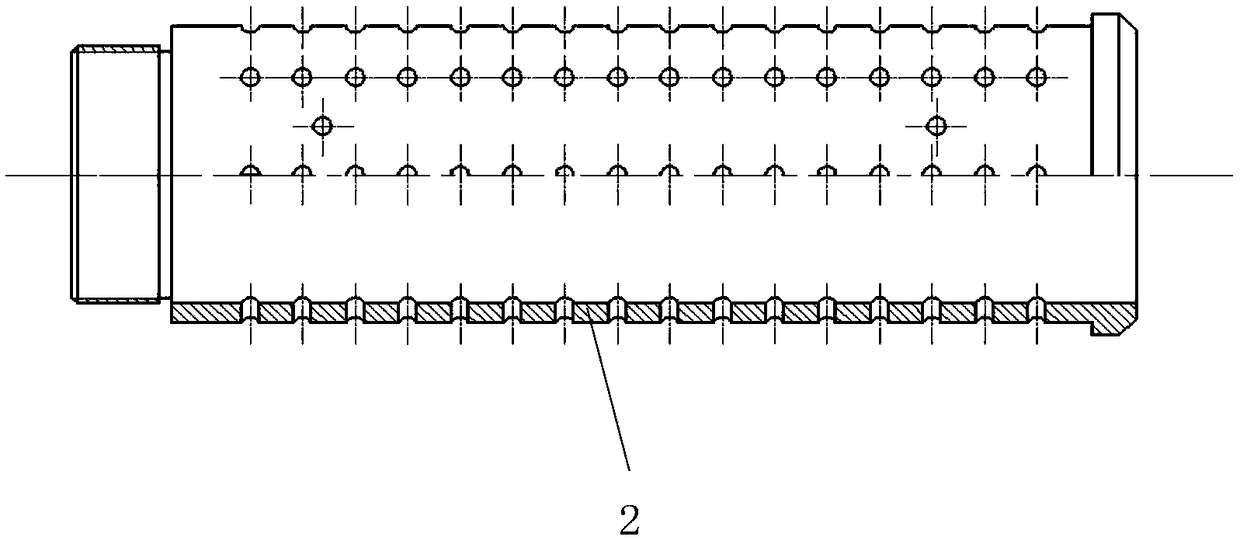

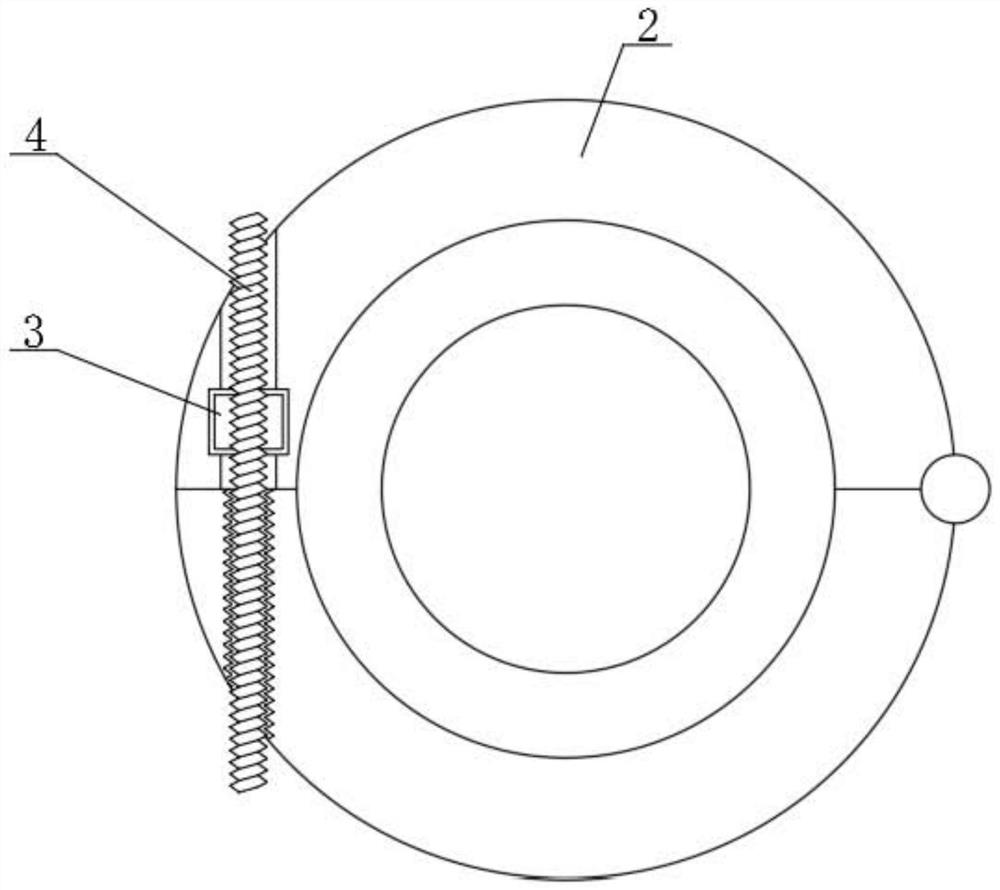

Multilayer filter net pipe of petroleum pipe

InactiveCN109882136ASolve the problem that the structure is complicated and the filter layer is easily deformed to affect the filtering effectSolve the problem that easy deformation affects the filtering effectFluid removalEngineeringOil production

The invention discloses a multilayer filter net pipe of a petroleum pipe. A center main pipe, an outer protective casing and filter net core pipes are arranged; the center main pipe (2) is in a shapeof a drilled sieve pipe with sieve holes being drilled in a pipe body section; a pipe body of the drilled sieve pipe of the center main pipe (2) is externally connected with the 1-6 layers of filter net core pipes (4) in a wrapped mode; the filter net core pipes (4) are externally connected with the outer protective casing in a wrapped mode; the two ends of the outer protective casing and the filter net core pipes (4) are fixedly connected with linkage rings (3); and the linkage rings (3) are fixedly connected to a pipe body of the center main pipe (2). When being used, the multilayer filter net pipe is the same as an existing oil well sieve pipe with the filtering function, according to design requirements, the two ends are assembled on an oil production well casing, and then operation ofoil production, sand prevention and filtering can be conducted.

Owner:XIAN ANT PETROLEUM TECH

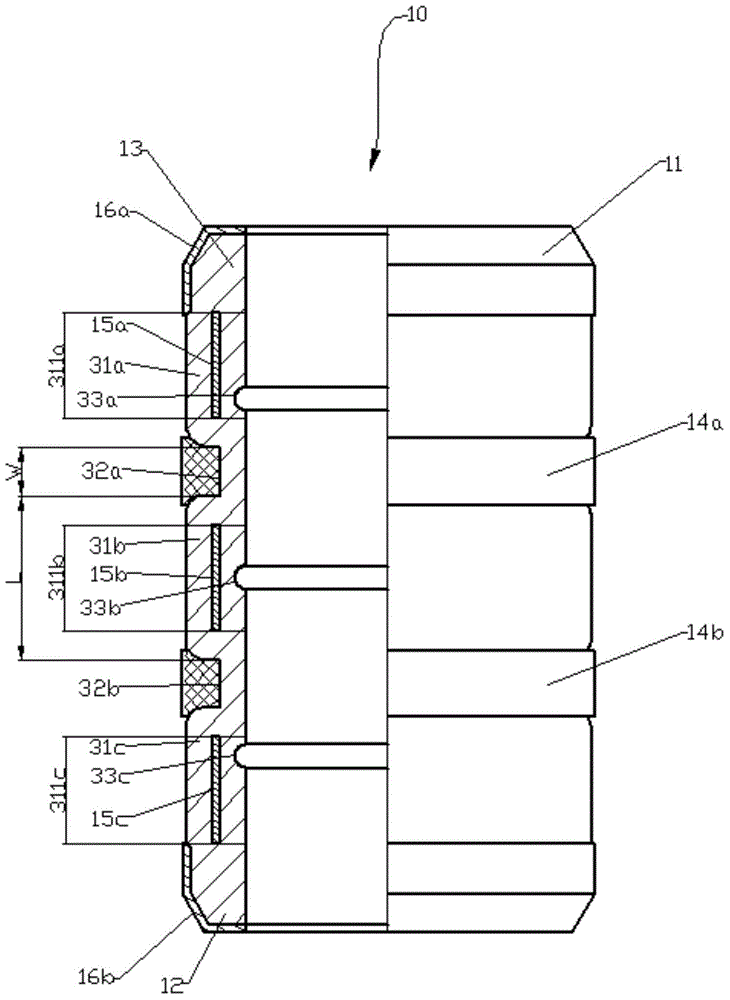

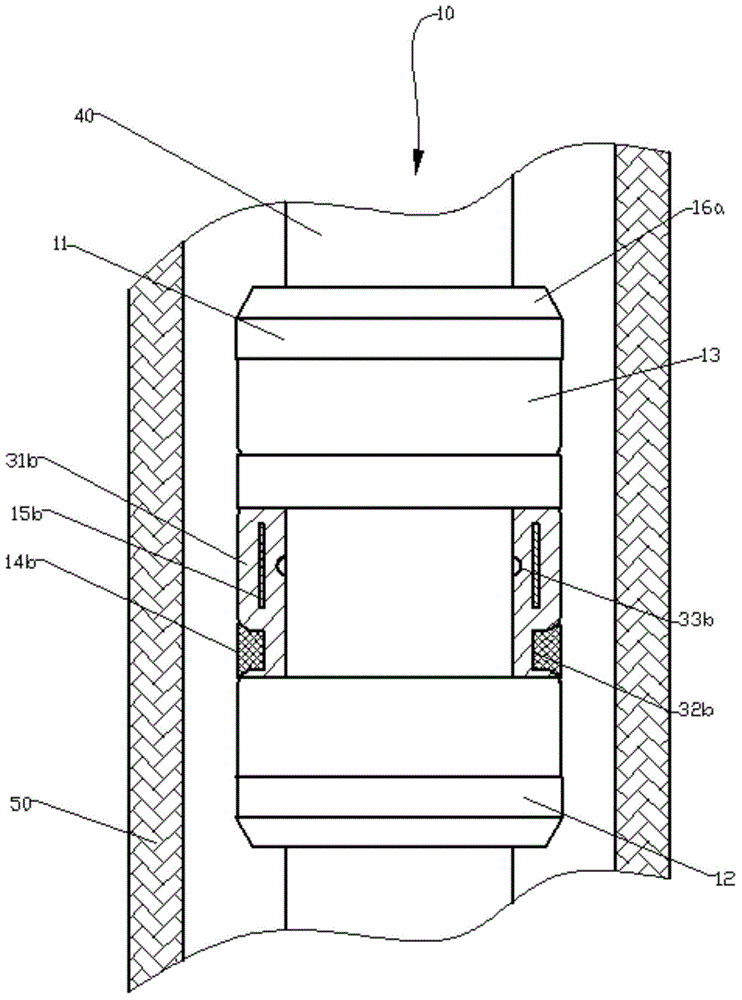

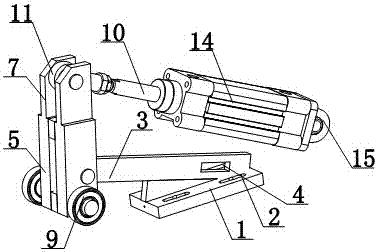

A Solidified Probe of Nuclear Magnetic Resonance Logging Tool

ActiveCN103670370BCapable of resisting downhole high pressureNo pressure compensation structure existsSurveyNMR - Nuclear magnetic resonanceHigh pressure

The invention relates to the technical field of downhole measurement, in particular to a nuclear magnetic resonance logger curing probe. The nuclear magnetic resonance logger curing probe comprises a probe body used for measurement and a permeability shell, the permeability shell wraps the probe body, and the portion between the permeability shell and the probe body is gapless. Relatively speaking, the nuclear magnetic resonance logger curing probe has the downhole high-pressure resistance. In addition, a pressure compensation structure does not exist, oil filling and oil supplying operations are not needed in the well descending process every time, and therefore the well descending operation is easier and more convenient to conduct, and the dangers of pressing explosion do not exist.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Double-filtering layer meander circular seam self-cleaning sieve tube

The invention discloses a double filtering-layer meandering circumferential weld self-cleaning sieve tube which is composed of a filter element and a basal tube; the filter element is embedded in a stepped hole at the side wall of the basal tube and is composed of a central cap, a plurality of filtering rings, a fixed ring and a protective cover. The size of the inner diameter of the filtering rings are increased one by one and the inner wall of each filtering ring is a double-stair shape, the outer wall of each filtering ring is an inverted double-stair shape. The outer wall of the central cap is an inverted double-stair shape and the central cap are sheathed in the filtering ring with the smallest inner diameter; all the filtering rings are axially sheathed together according to the size order of the inner diameter. The inner wall of the fixed ring is a double-stair shape and the filtering ring with the largest inner diameter is sheathed in the fixed ring; the outer wall of the fixed ring is an inverted double-stair shape and the upper part of the fixed ring is a conical surface and the lower part thereof is a cylindrical surface. The protective cover is covered on the conical surface of the outer wall of the fixed ring, a plurality of air vent windows are opened on the top surface of the protective cover. The double filtering-layer meandering circumferential weld self-cleaning sieve tube can filter the thin-fine sand, the permeability is high, the filter precision is high, and the filtering seam has extremely strong damage-resistance capacity and is not easily to block.

Owner:浙江省星炬科技有限公司

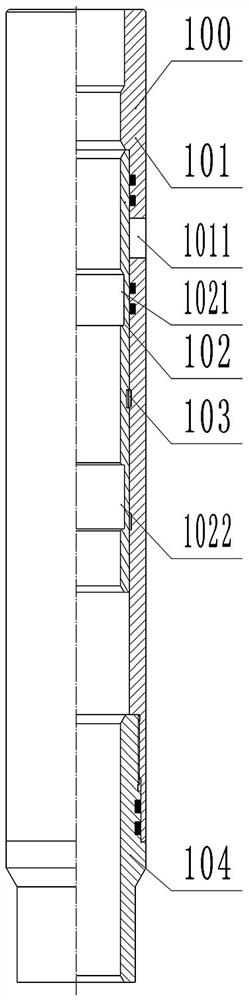

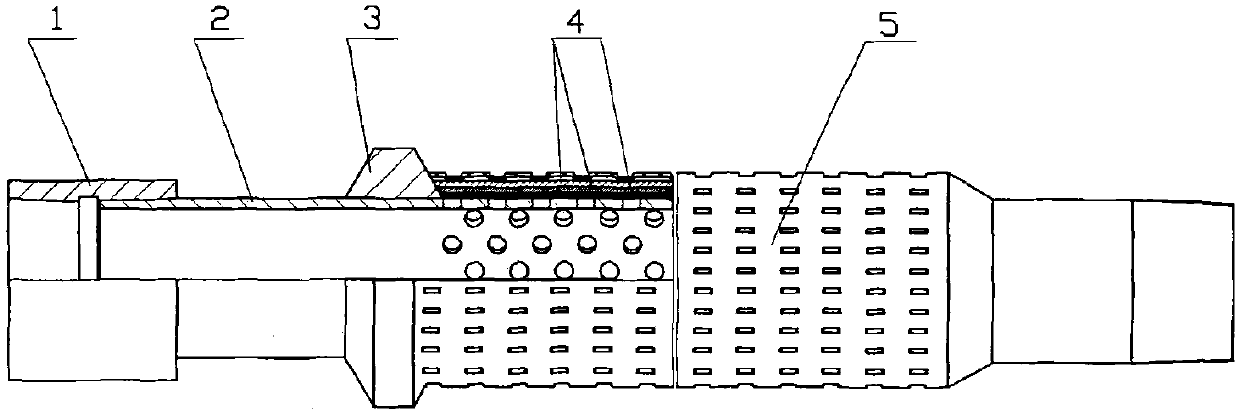

Accumulator for downhole operation and method of use

ActiveCN106837245BConvenient downhole operationSimple structureBorehole/well accessoriesEngineeringEnergy storage

Owner:CHINA PETROLEUM & CHEM CORP +1

Rubber cartridges for packers and packers

ActiveCN105201445BContainment is effectiveConvenient downhole operationSealing/packingAxial pressureEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Filter screen core pipe for oil transportation pipeline

InactiveCN109113678ASolve the problem that the structure is complicated and the filter layer is easily deformed to affect the filtering effectSolve the problem that easy deformation affects the filtering effectFluid removalFiltrationOil production

The invention discloses a filter screen core pipe for an oil transportation pipeline. The filter screen core pipe is provided with a center main pipe, outer protection sleeve pipes, and filter core pipes. The center main pipe is a drilling screen pipe type center main pipe (2) that is drilled with screen apertures in a pipe body segment; the outside of a pipe body of the drilling screen pipe of the center main pipe (2) is covered with 1-6 layers of filter core pipes (4); the outsides of the filter core pipes are coated with the outer protection sleeve pipes; both ends of the outer protection sleeve pipes and the filter core pipes (4) are fixedly connected with connecting rings (3); and the connecting rings (3) are fixedly connected with the pipe body of the center main pipe (2). When the filter screen core pipe is used, according to design requirements, both ends are assembled on an oil production well pipe, which is same as conventional oil well screen pipes with filtration, and thenoil production sand prevention filtration operation can be performed.

Owner:XIAN ANT PETROLEUM TECH

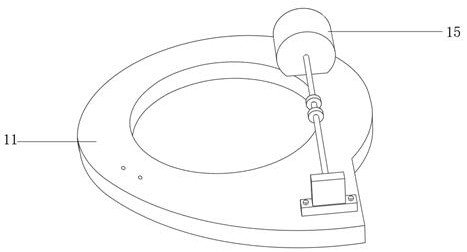

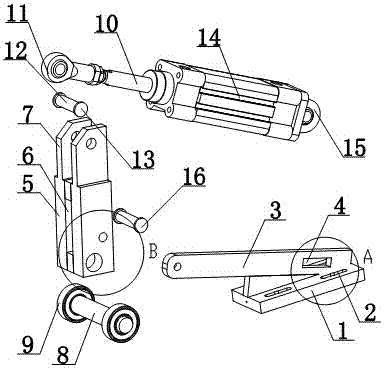

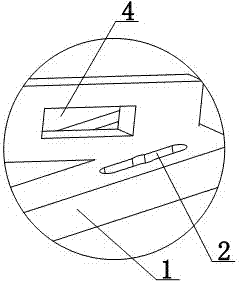

Mobile adjustable mechanical arm for lifting rope suspension

The invention discloses a mobile adjustable mechanical arm for suspending ropes, which comprises a mounting base and a supporting base. The upper end is a free end; the support seat is provided with a mounting groove, the upper end of the support arm is arranged in the installation groove, the end of the support seat is provided with a mounting frame, the bottom end of the support seat is provided with a connecting shaft, and the two ends of the connecting shaft are provided with The moving wheel, the upper end of the support arm is connected with the mounting base through the fixing bolt, the mounting frame is provided with an adjusting tube, one end of the adjusting tube is provided with an adjusting ring, the adjusting ring is set in the mounting frame, the mounting frame and the adjusting ring are connected by a docking shaft, and the docking shaft The two ends of the adjustment tube are provided with clasps, and the clasps are arranged on the outer wall of the installation frame; the other end of the regulating tube is provided with a fixing seat, and the fixing seat is provided with a suspension ring. The present invention can install the mechanical arm at the well head, so that objects can be conveniently input to the bottom of the well through the hanging rope, and the underground operation is convenient.

Owner:刘昕

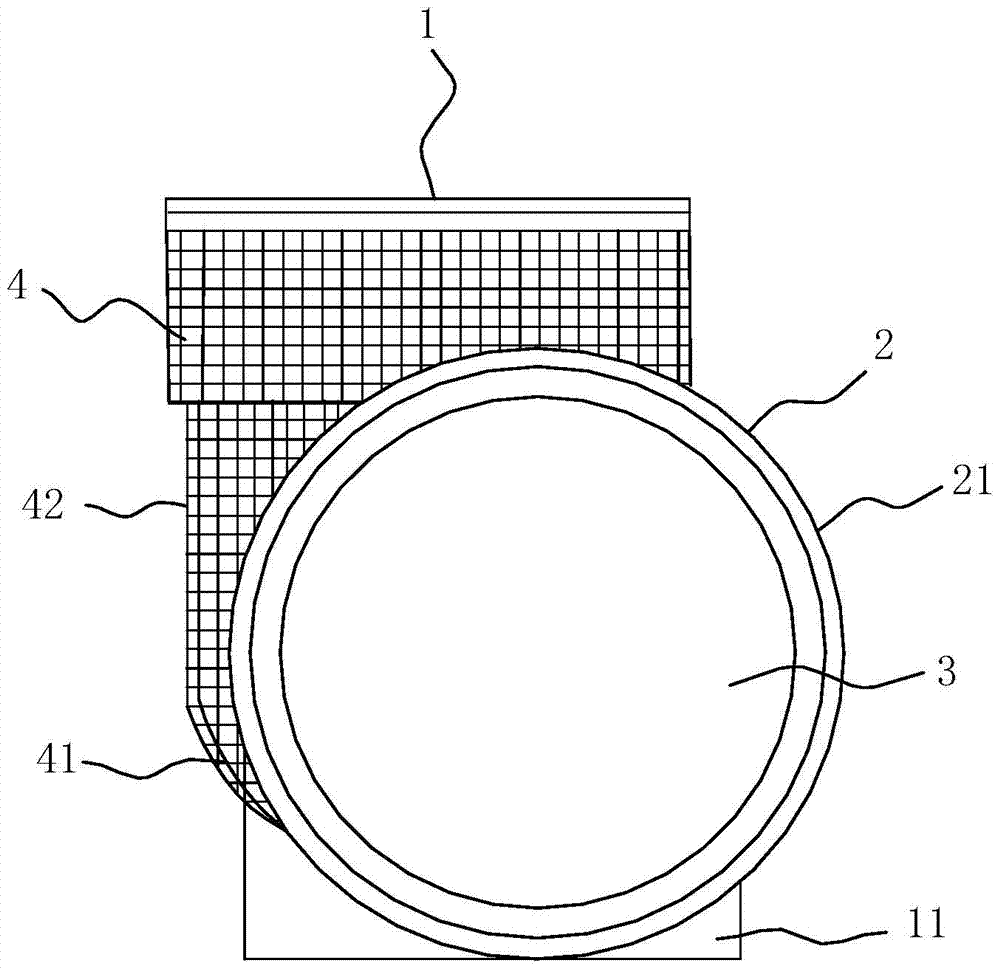

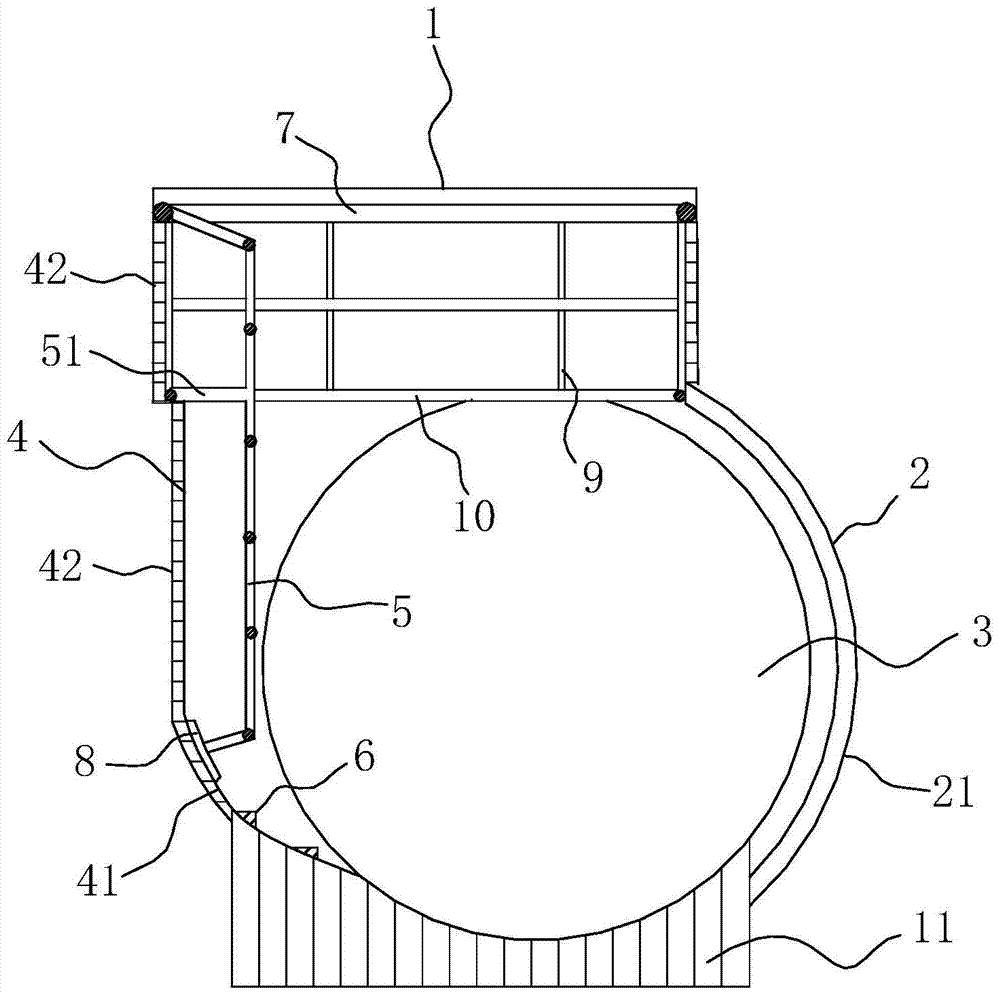

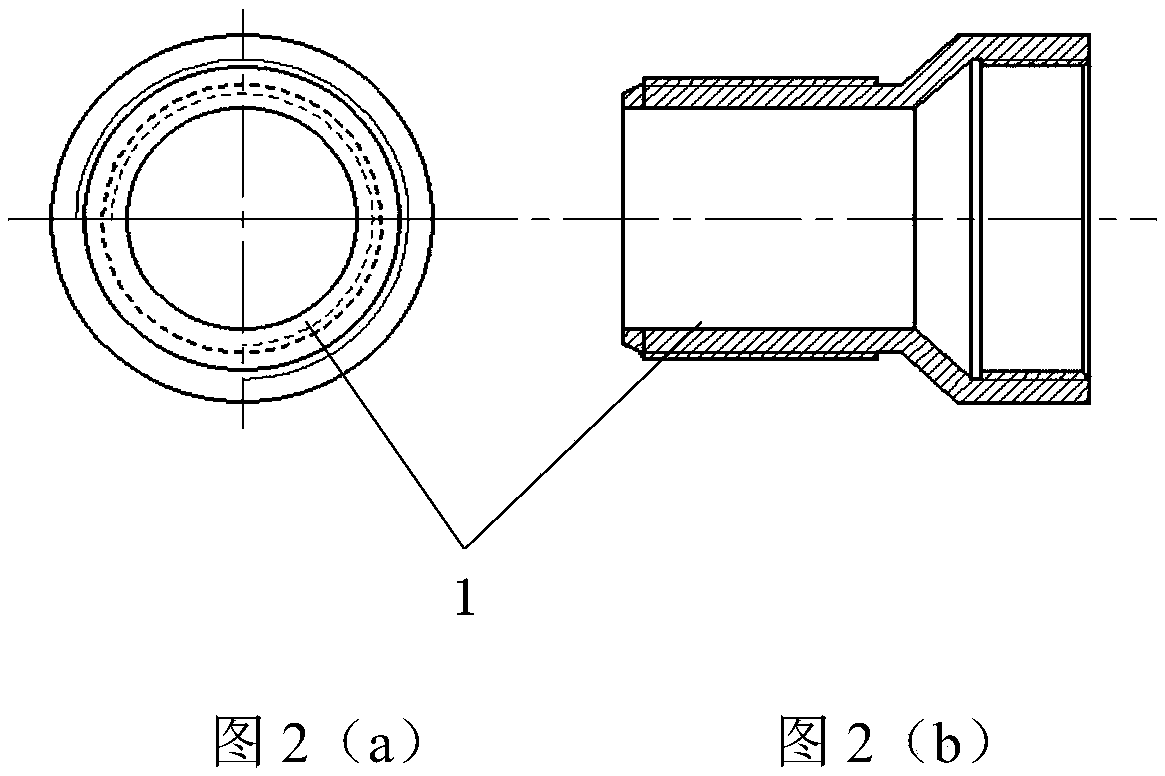

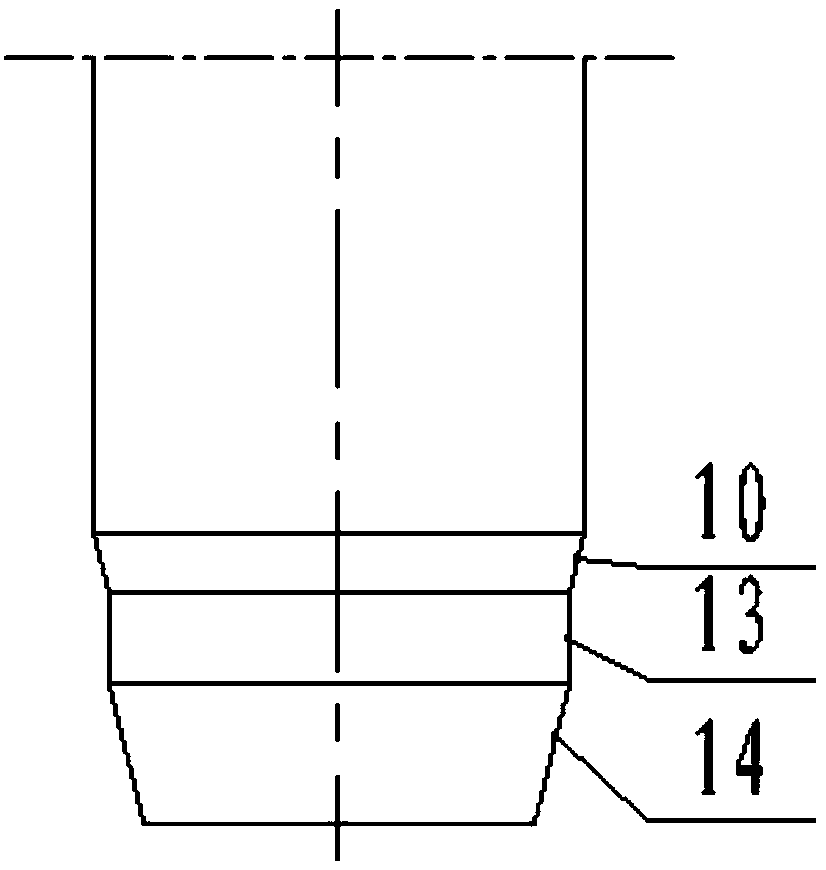

A plastic offset inspection well

ActiveCN105019544BSimple structureEasy to processArtificial islandsSewerage structuresCorrosionWellhead

The invention relates to water supply and drainage facilities, in particular to a more convenient plastic offset inspection well. The offset inspection well includes the upper part as the inspection wellhead, and the lower part as a tubular seat for connecting with the drainage pipe; the inspection wellhead is vertically upward, the seat is arranged horizontally, and the inspection wellhead is located on the axial side of the seat; The two ends of the seat body and the middle part of the seat body are perpendicular to the inspection wellhead, at least two places are provided with pipe sockets connected to the drainage pipe; the inspection wellhead is extended downwards and a shell is provided, and the shell and the seat body form an intersecting combination , the lower end of the housing is smoothly connected with the seat body; the vertical section of the inner wall of the housing is provided with a ladder; the inner wall of the housing below the ladder is provided with a protruding stepping platform. The structure of the invention is simple, firm, easy to process, assemble and use, high in strength, durable, corrosion-resistant and low in cost.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

Downhole casing wire scraper

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

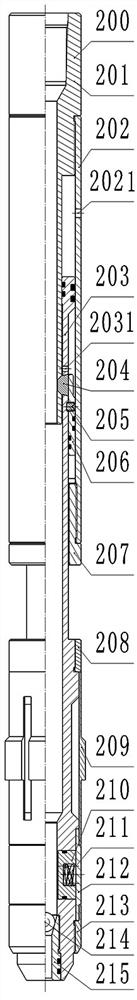

Hydraulic closing tool for closing sliding sleeve switch and sliding sleeve switch tool assembly

PendingCN114059964AEasy to moveReduce manufacturing costWell/borehole valve arrangementsSealing/packingManufacturing cost reductionClassical mechanics

The invention relates to a hydraulic closing tool used for closing a sliding sleeve switch and a sliding sleeve switch tool assembly, the hydraulic closing tool comprises a tool body, a pressing center hole, a lifting and hanging lock tongue and an inwards-shrinking elastic piece, and further comprises a positioning boss and an outwards-extending elastic piece, the positioning boss has the set up-down width size, the upper and lower groove width of the annular positioning groove in the multiple sliding sleeve switches is gradually increased from top to bottom corresponding to an underground pipe column with the multiple sliding sleeve switches, and in the process that the tool main body drives the positioning boss to move downwards, and when the positioning boss extends outwards to be matched with the annular positioning groove in the corresponding sliding sleeve switch in a positioning and inserting mode, the hydraulic closing tool is lowered in place. The positioning boss is controlled by the outward-extending elastic piece to act, the lifting and hanging lock tongue is controlled by fluid pressure and the inward-retracting elastic piece, the lifting and hanging lock tongue and the inward-retracting elastic piece do not interfere with each other, manufacturing cost can be effectively reduced, and reliable action is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Three-layer tubing string injection device

ActiveCN105275411BSolve the water injection methodImprove water injection efficiencyDrilling rodsFluid removalInter layerReducer

The invention relates to a three-layer tubing string dispensing device, which comprises an outer layer pipe string, an intermediate layer pipe string and an inner layer pipe string; one end of the outer layer pipe string is provided with an outer layer connecting assembly, and One end of the pipe string is provided with an intermediate layer connection assembly, and one end of the inner layer pipe string is provided with an inner layer connection assembly; the other end of the outer layer pipe string is connected to the outer layer water injection pipe through the outer layer reducing joint, and the middle layer The other end of the layer pipe string is connected to the middle layer water injection pipe through the intermediate layer reducing joint, and the other end of the inner layer pipe string is connected to the inner layer water injection pipe through the inner layer reducing joint. The oil layer of the three-layer oil well can be injected separately at the same time, and the water injection efficiency of the oil well can be improved. The overall structure is simple, easy to manufacture and install, and has strong practicability.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

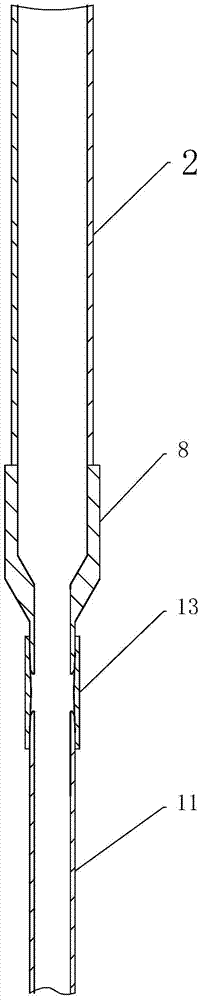

Sand control screen pipe with welded-on filtering blocks and preparation method for sand control screen pipe with welded-on filtering blocks

InactiveCN104929589AImprove reliabilityIncrease filter areaFluid removalUltimate tensile strengthCivil engineering

The invention discloses a sand control screen pipe with welded-on filtering blocks and a preparation method for the sand control screen pipe with the welded-on filtering blocks. The sand control screen pipe comprises a base pipe and the plurality of filtering blocks; the outer side of the pipe wall of the base pipe is provided with a plurality of oval stepped grooves, and bottoms of the oval stepped grooves are provided with through holes communicated with the interior of the base pipe; the filtering blocks and the oval stepped grooves are identical in shape, and the filtering blocks are inserted into the oval stepped grooves in one-to-one correspondence; fitting surfaces of the filtering blocks and the oval stepped grooves are welded into a whole. The sand control screen pipe has the advantages that the inner diameter and the outer diameter of the sand control screen pipe are identical to those of the base pipe to make it convenient for descending into a horizontal well; the filtering blocks and the base pipe are welded into a whole to guarantee integral strength and reliability of the pipe.

Owner:TANGSHAN SENJIN GASOLINEEUM EQUIP TRADE IND

Underground long-acting electromagnetic flowmeter for water well separate injection network

ActiveCN111811594AImprove convenienceImprove installation efficiencySurveyVolume meteringElectromagnetic flowmeterElectrical and Electronics engineering

The invention relates to the technical field of electromagnetic flowmeters, in particular to an underground long-acting electromagnetic flowmeter for a well separate injection network. The flowmeter comprises a measuring pipe, a mounting pipe is arranged on the outer side of the measuring pipe; a rotating block is rotationally connected to the inner side of the mounting pipe at the top end; the inner side of the rotating block is fixedly connected with a first threaded rod; a second threaded rod is arranged on the inner side of the mounting pipe at the bottom end; the inner side of the secondthreaded rod is fixedly connected with a first electrode; a third threaded rod is fixedly connected to the inner side of the mounting pipe at the top end; the inner side of the third threaded rod is slidably connected with a second electrode. The top end of the third threaded rod is fixedly connected with a rotary drum; the top end of the rotary drum is rotationally connected with a mounting plate. According to the flowmeter, with the arrangement of the mounting pipe, the rotating block, the first threaded rod, the first electrode and the third threaded rod, the convenience of device assemblyis improved, time and labor are saved, the device mounting efficiency is improved, downhole operation is facilitated, the device is fixed stably, and the use safety of the device is improved.

Owner:西安罗格石油仪器有限公司

Oil screen central main pipe

The invention discloses an oil screen central main pipe. The oil screen central main pipe is provided with a center main pipe, an outer sheath pipe and a filter net core tube; and the central main pipe is a drill hole screen pipe type central main pipe (2) with a screening hole drilled in a pipe body section, a drill hole screen pipe body of the central main pipe (2) is externally connected with 1-6 layers of screen net core pipes (4) in a coating mode, the filter net core pipes (4) are externally connected with the outer sheath pipe in a coating mode, linkage rings (3) are fixedly connected to two ends of the outer sheath pipe and the filter net core pipes (4), and the linkage rings (3) are fixedly connected to a pipe body of the central main pipe (2). When the oil screen central main pipe is used, like an existing filtering oil well screen pipe, according to the design requirements, both ends of the oil screen central main pipe are assembled on an oil production well pipe, and the oil production and sand prevention filtration operation can be performed.

Owner:XIAN ANT PETROLEUM TECH

Oilfield downhole depth measurement device and method

The invention belongs to the field of oilfield downhole working tools, and particularly relates to an oilfield downhole depth measurement method. The oilfield downhole depth measurement method refersto an upper joint, a piston sleeve, a piston, a central pipe, a spring protection sleeve, a spring, a lower joint and a sealing ball. The upper joint and the lower joint are connected to the upper andlower ends of the central pipe through threads correspondingly; the upper end of the piston sleeve is connected to the outer side of the upper joint through a thread; the piston is arranged in an annular space between the piston sleeve and the central pipe; a liquid passing hole is formed in the position, corresponding to the piston, on the central pipe; after pressure is pumped into the centralpipe, high pressure liquid enters a sealed space in the upper side of the piston through the liquid passing hole, and then the piston is pushed to move; and an elastic hanging claw is arranged on thelower portion of the piston sleeve, and a bulge is arranged on the outer side of the lower end of the elastic hanging claw. The precise depth of related downhole tools is measured by looking for a casing hoop, and the characteristics of simple structure and convenient use are achieved.

Owner:大庆市嘉钰机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com