Rubber sleeve for packer and packer

A technology of packers and rubber cartridges, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of single rubber cartridges prone to wrinkles, short effective isolation length, and inability to guarantee contact stress, etc. problems, to achieve the effect of improving the safety of well entry and sealing reliability, increasing the effective isolation length, and applicable to a wide range of well diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

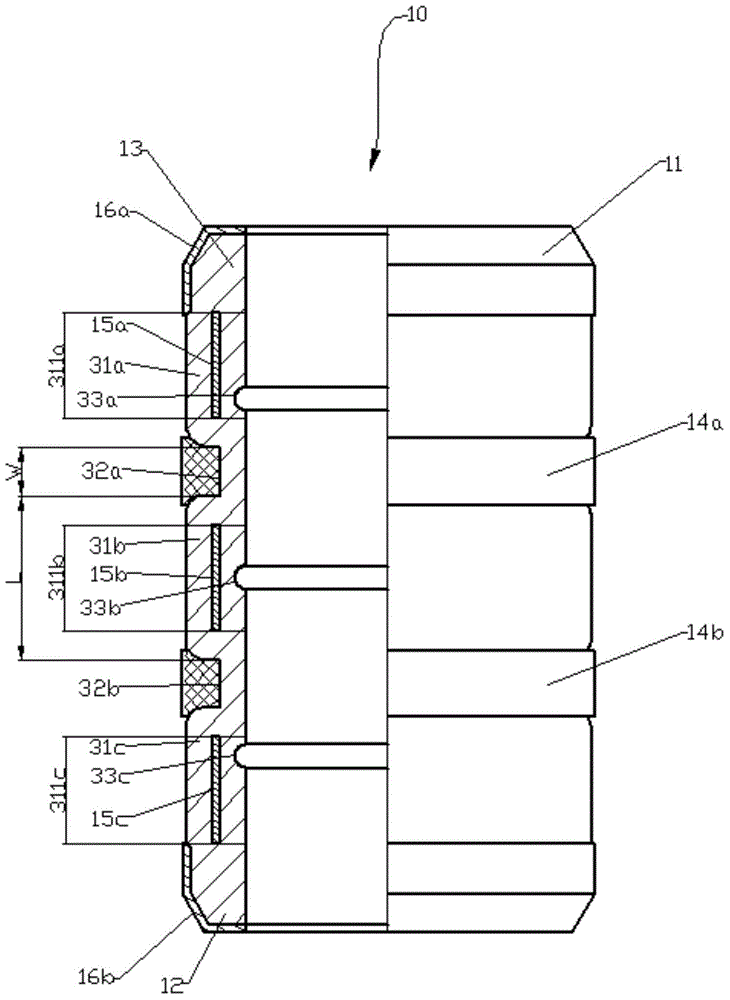

[0021] The present invention will be further described below in conjunction with accompanying drawing.

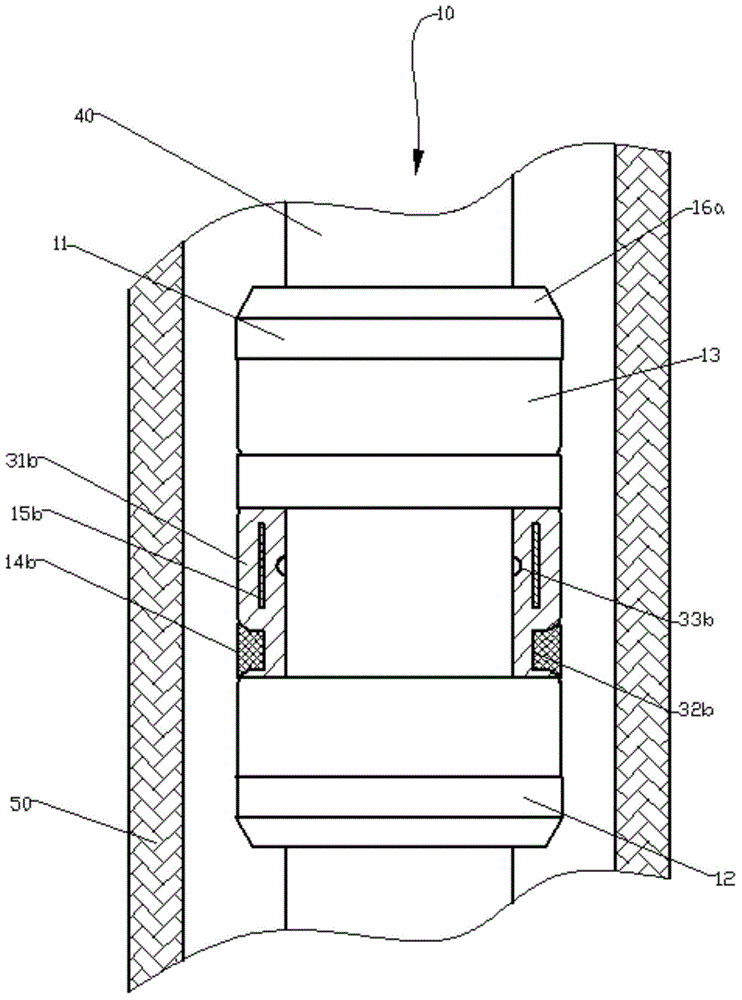

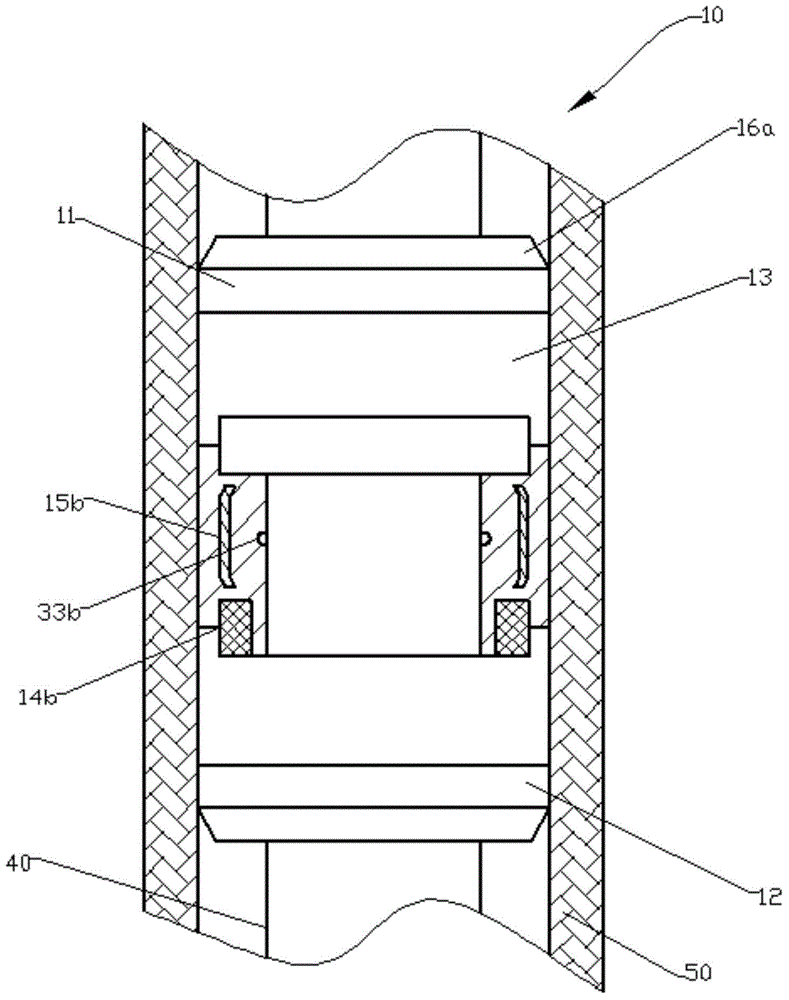

[0022] figure 1 The overall structure of the rubber cartridge 10 for the packer (hereinafter referred to as the rubber cartridge 10 ) is schematically shown. The rubber cartridge 10 includes a hollow elastic cylinder 13 and several supports wrapped on the circumferential side wall of the cylinder 13. figure 1 Two supports 14a and 14b are schematically shown in . The cylinder body 13 can be selected from rubber with higher hardness to ensure that the cylinder body 13 will not become soft under high temperature and high pressure conditions, resulting in contact with the well wall 50 (see figure 2 ) The contact stress drops.

[0023] A plurality of supports divides the barrel 13 into a plurality of expansion zones, such as figure 1 The expansion zones 31a, 31b and 31c in. In Packer 40 (see figure 2 ) during setting, exert pressure on the ends 11 and / or 12 of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com