Oilfield downhole depth measurement device and method

A technology for depth measurement and oilfield wells, which is used in measurement, earthmoving, wellbore/well components, etc. It can solve the problems of unimproved measurement accuracy, high technical difficulty, and high logging costs, saving testing costs and simple principles. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

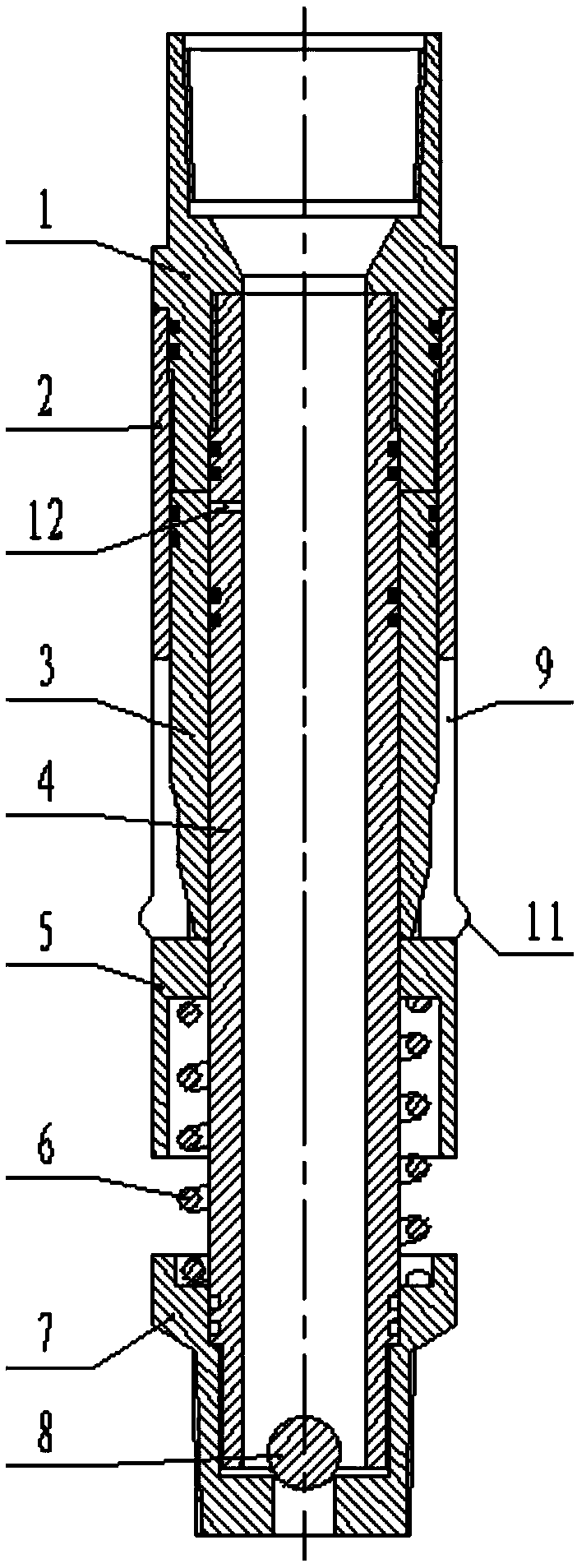

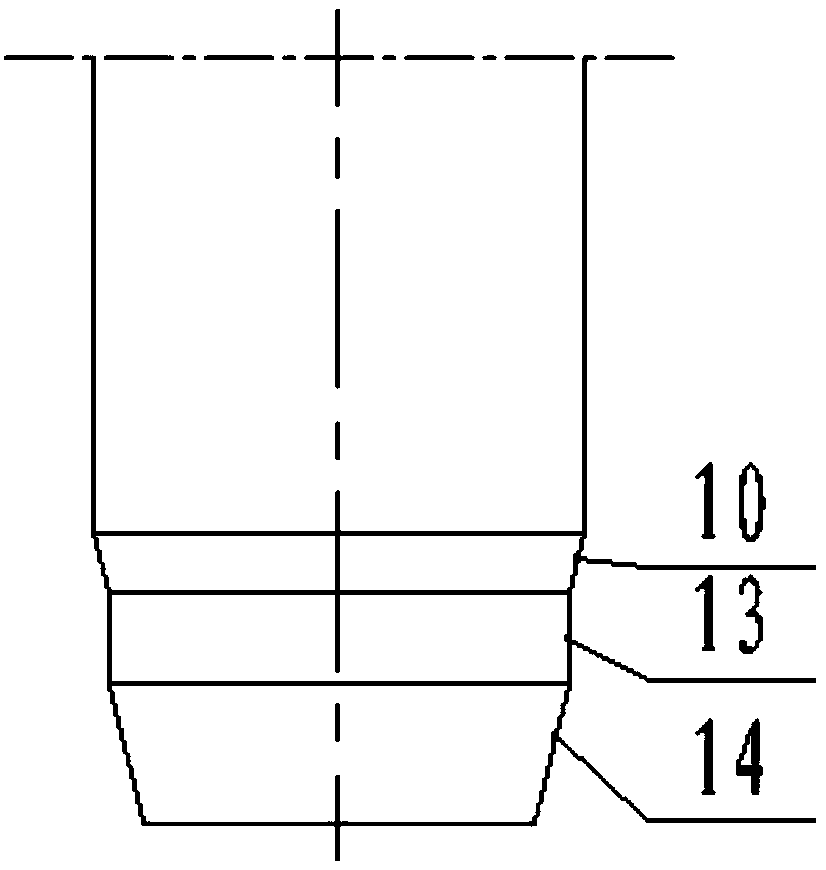

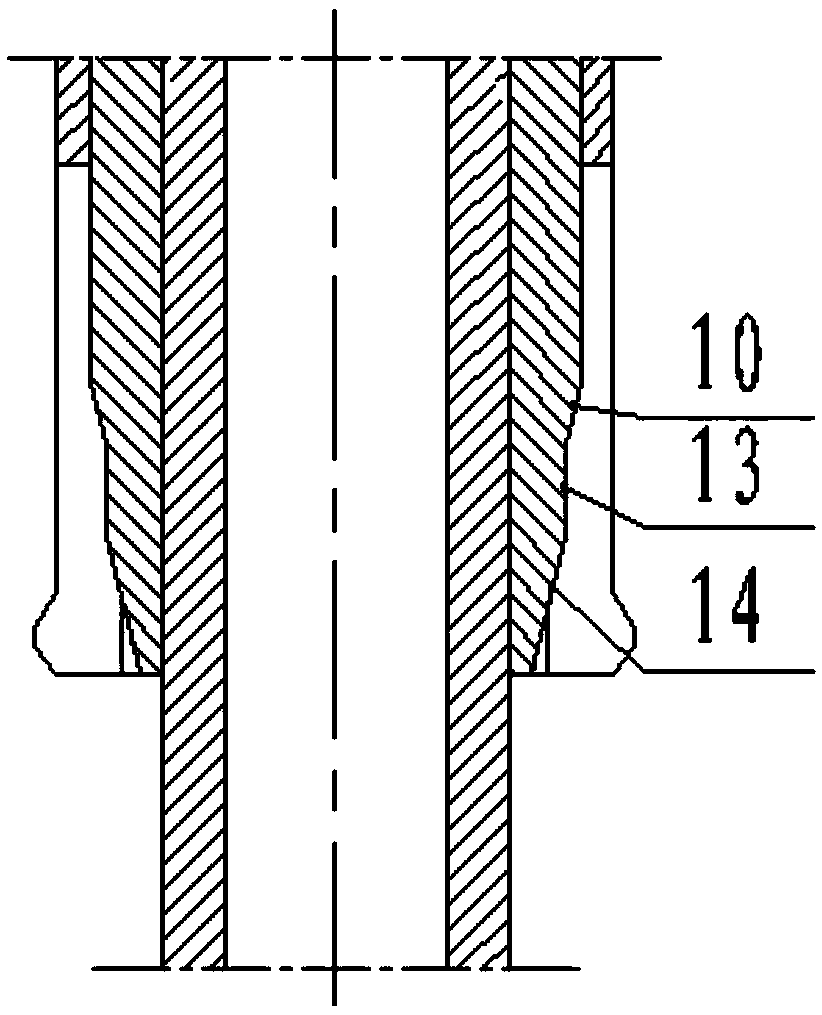

[0026] The present invention will be further described below in conjunction with the drawings:

[0027] An oil field downhole depth measuring device, comprising an upper joint 1, a piston sleeve 2, a piston 3, a central tube 4, a spring sheath 5, a spring 6, a lower joint 7 and a sealing ball 8. The upper joint 1 and the lower joint 7 are respectively threaded Connected to the upper and lower ends of the central pipe 4, the upper end of the piston sleeve 2 is connected to the outer side of the upper joint 1 through threads, and the piston 3 is arranged in the annular space between the piston sleeve 2 and the central pipe 4.

[0028] The central pipe 4 is provided with a liquid passage hole 12 corresponding to the piston 3. After being pressed into the central pipe 4, the high-pressure liquid enters the closed space on the upper side of the piston 3 through the liquid passage hole 12, and then pushes the piston 3 to move.

[0029] The lower part of the piston sleeve 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com