Hydraulic closing tool for closing sliding sleeve switch and sliding sleeve switch tool assembly

A sliding sleeve switching and closing tool technology, applied in wellbore/well components, wellbore/well valve device, earthwork drilling and other directions, can solve the problem of high tool precision requirements, achieve simple overall structure, reliable action, The effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

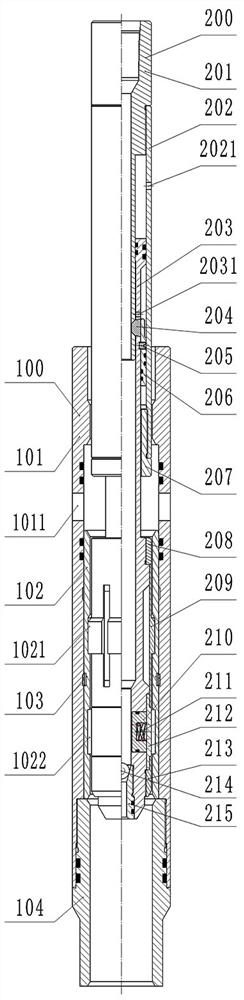

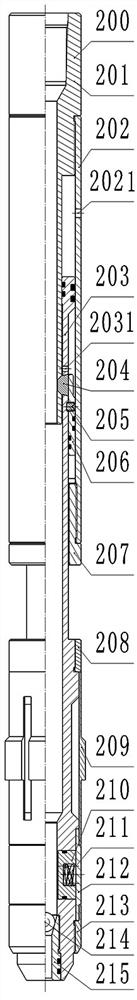

[0086] Such as Figure 1 to Figure 7 As shown, the slide switch tool assembly in this embodiment as a whole includes a paired slide switch 100 and a hydraulic closing tool 200, the relationship between the slide switch 100 and the paired hydraulic closing tool 200 is similar to that of a key and a lock , one key corresponds to one lock, and for a downhole pipe string with multiple sliding sleeve switches 100, the hydraulic closing tool 200 that is lowered into the inside of the downhole pipe string can only be matched with the corresponding sliding sleeve switch 100. Close only the selected slide switch.

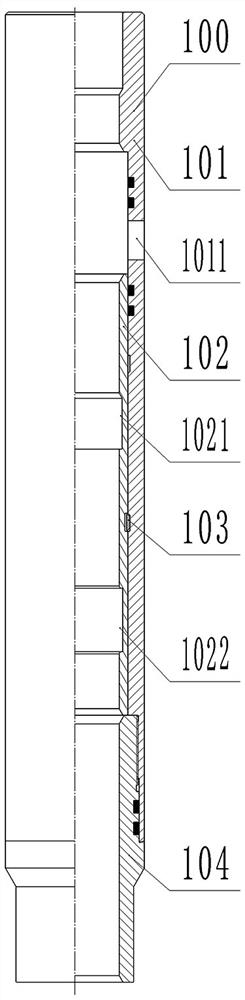

[0087] Such as figure 2 As shown, the sliding sleeve switch 100 is used for serial connection on the downhole pipe string, and is composed of an outer sleeve 101, an inner sliding sleeve 102, a locking ring 103 and a lower joint 104. The outer sleeve 101 is connected with the downhole pipe string through threads, and the outer sleeve 101 is provided The communication flow...

Embodiment 2

[0121] The main difference between it and Embodiment 1 is that in Embodiment 1, the force of the compression spring is directly overcome by pressing, and the lifting padlock tongue is driven by the fluid pressure to extend outward, so as to realize the engagement with the lifting padlock groove on the inner sliding sleeve. In this embodiment, the lifting lock tongue is telescopically assembled on the power piston in the radial direction, and the power piston is provided with an elastic member for driving the lifting lock tongue to protrude. The lower pressure ring, corresponding to the two pressure rings, is provided with top pressure springs respectively. The two top pressure springs are set on the power piston and apply elastic force to the two pressure rings to force the two pressure rings to move towards each other. , the pressing spring here is equivalent to the retractable elastic member, but the elastic force it exerts can only indirectly drive the lifting padlock tongue...

Embodiment 3

[0125] The main difference between it and Embodiment 1 lies in that in Embodiment 1, the lifting lock tongue is driven to protrude by pressing, and the sliding sleeve switch is closed by driving the power piston upward by continuing to press. In this embodiment, the power piston is canceled, and after the lifting lock tongue is pushed out by pressing, the coiled tubing and the hydraulic closing tool are directly lifted up to drive the inner sliding sleeve upward to close the sliding sleeve switch.

[0126] Of course, it can also be applied to the situation where it is necessary to drive the inner sliding sleeve down to close the sliding sleeve switch. When the positioning boss matches the annular positioning groove in the corresponding sliding sleeve switch, the wellhead is pressed, and the lifting lock tongue is extended. To engage with the corresponding lifting padlock slot, while maintaining the pressing state, continue to lower the coiled tubing and hydraulic closing tool, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com