Filter screen core pipe for oil transportation pipeline

A technology for oil pipelines and filter cores, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of complicated oil well screen structure, affecting the filtering effect, and easy deformation of the filtering layer to achieve the filtering effect Stable, simple and practical structure, easy downhole operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

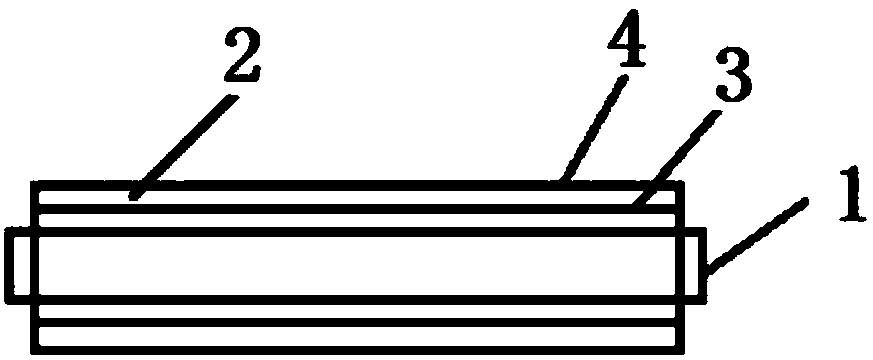

[0016] as attached figure 1 In the shown embodiment, the present invention is provided with: a central supervisor 2, a screen core pipe 4, an outer sheath pipe 5, the central supervisor 2 is a drilled sieve tube type central supervisor with sieve holes drilled in the pipe body section, and the outer sheath The tube 5 is the outer sheath tube of the grooved bridge-type slotted screen tube punched with filter seams on both sides. The drilled screen tube body of the central main pipe 2 is surrounded by three layers of filter core tubes 4 with different diameters. The outside of the filter core tube 4 is connected to the outer sheath tube 5 of the groove bridge type punching screen, and the outer sheath tube 5 of the groove bridge type punching screen and the two ends of the filter core tube 4 are fixedly connected to the joint. The ring 3 and the link ring 3 are fixedly welded on the central main pipe 2 pipe body.

[0017] Further, the outer sheath pipe of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com