Sand control screen pipe with welded-on filtering blocks and preparation method for sand control screen pipe with welded-on filtering blocks

A sand control screen and filter block technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problem of slotted screen slot width variation, insert screen block drop, and limited filtration area and other problems to achieve the effect of solving shedding, facilitating downhole operation and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

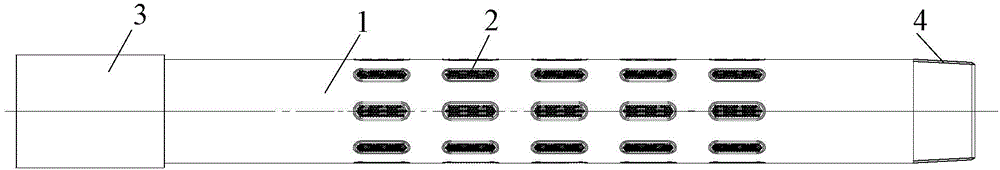

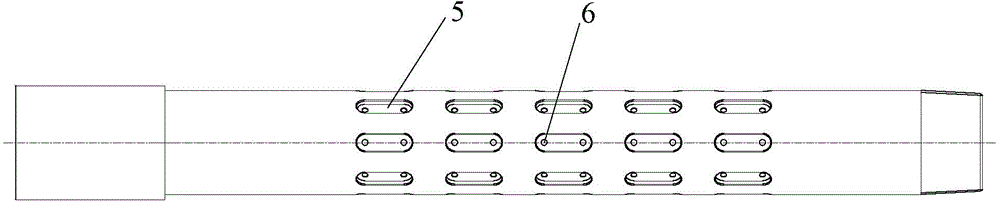

[0047] The sand control screen of the inlaid and welded filter block of this embodiment adopts a standard oil casing as the base pipe 1, mills out several oblong stepped grooves 5 on the outer side of the pipe wall of the base pipe 1, and drills at the bottom of the oblong stepped groove 5 A plurality of through holes 6 communicate with the inside of the base pipe 1, insert the filter block 2 in the oblong stepped groove 5, and then use argon arc welding or plasma welding to continue along the mating surface between the filter block 2 and the oblong stepped groove 5 Weld a circle, grind the welded part to integrate the filter block 2 and the base pipe 1, form a reliable sand-proof structure, ensure the overall strength and reliability of the pipe body, and completely solve the problem of filter block falling off, such as figure 1 and figure 2 shown.

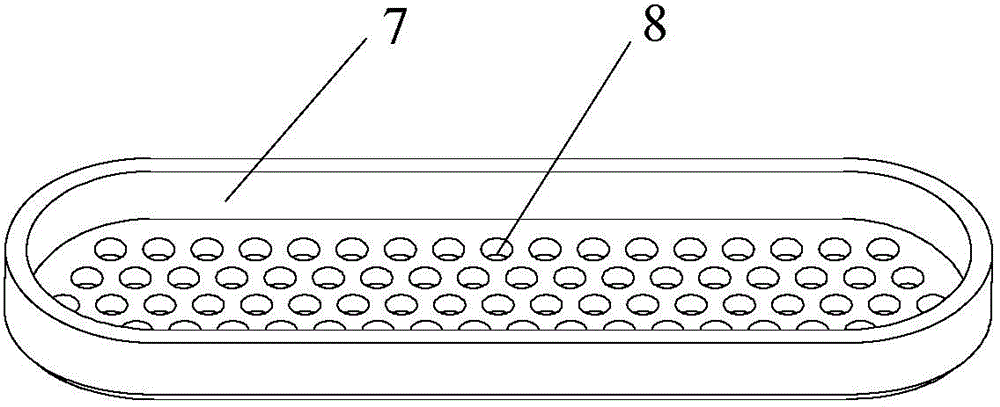

[0048] Such as image 3 and Figure 4 As shown, the filter block 2 is composed of a stainless steel perforated box 7 and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com