Submersible permanent magnet motor unit rotor with combined punching sheets

A technology of unit rotor and permanent magnet motor, which is applied in the direction of electrical components, manufacturing motor generators, magnetic circuit rotating parts, etc., can solve the problems of permanent magnet fragmentation, collision, and large eddy current loss of permanent magnets, etc., and achieve shortened length, The effect of low flux leakage and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the present invention will be further described:

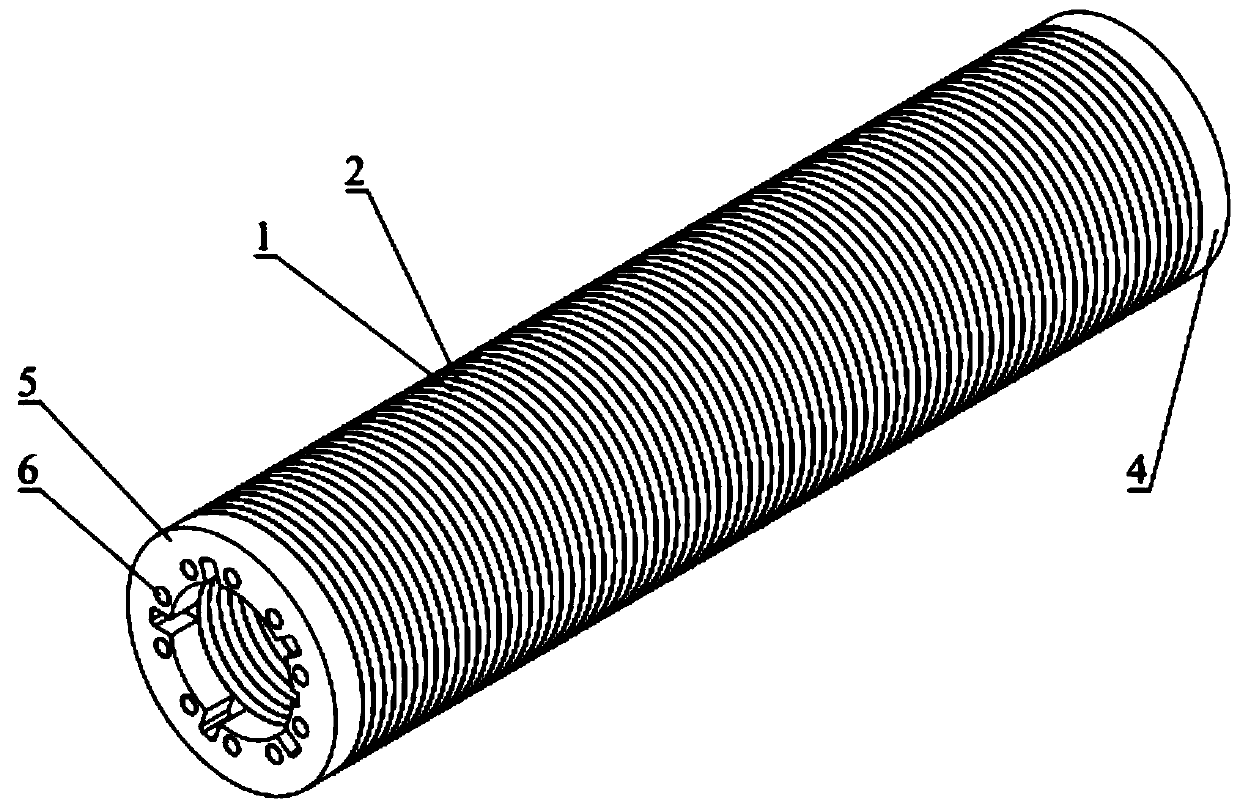

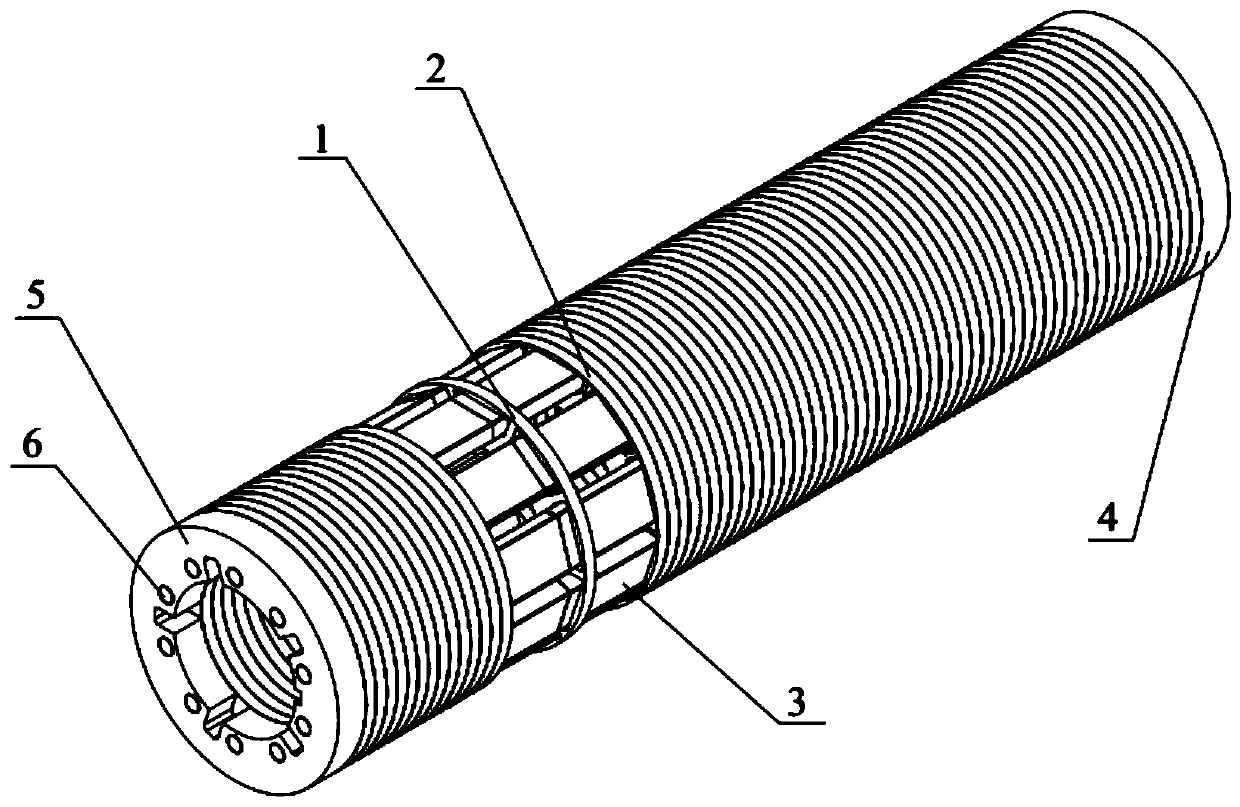

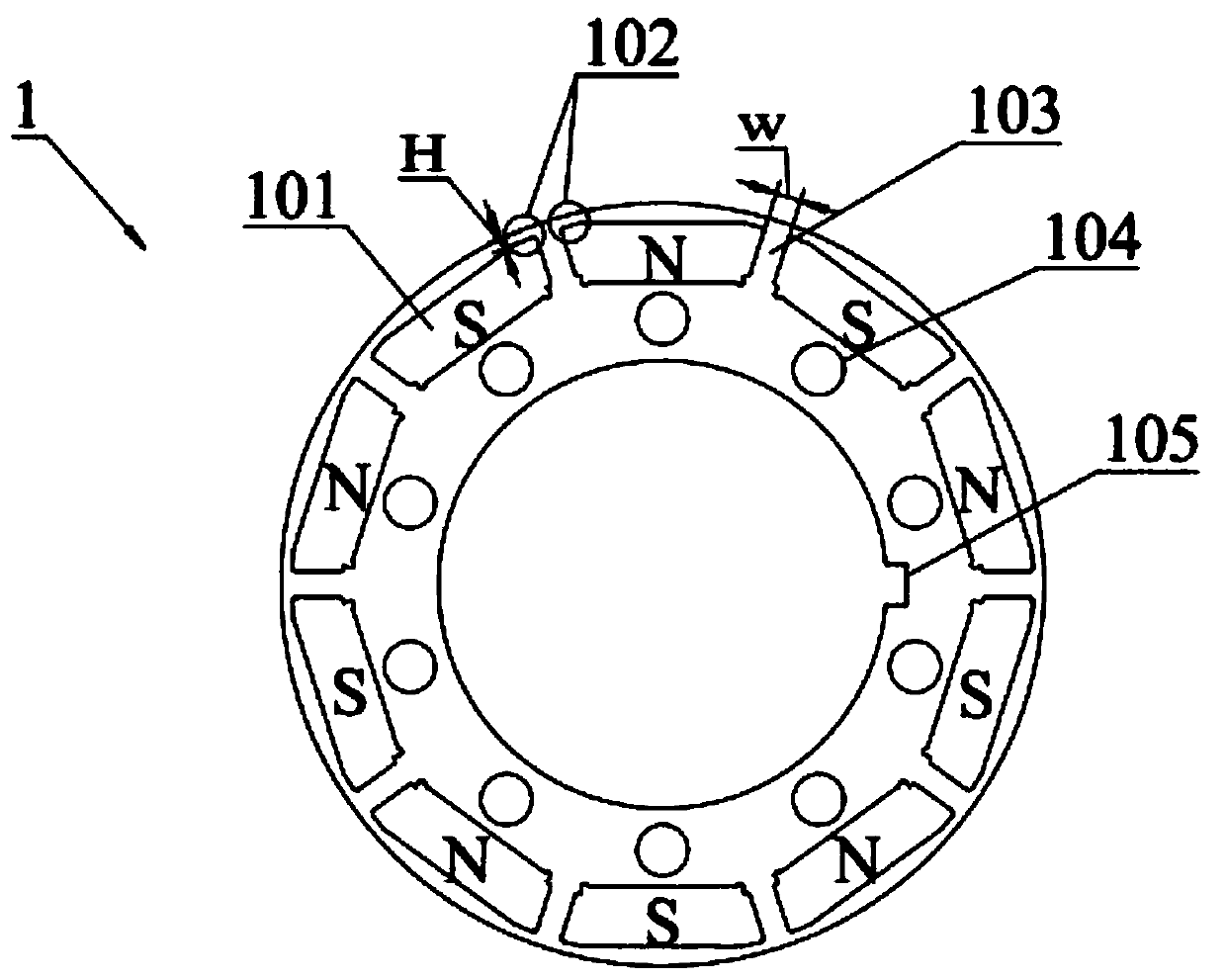

[0051] A unit rotor of combined stamping submersible permanent magnet motor, the unit rotor includes a high-strength iron core punch 1, a low-leakage magnetic core punch 2, a permanent magnet 3, an end plate A4, an end plate B5 and a locking rod 6;

[0052] The high-strength iron core punch 1 and the low-leakage magnetic core punch 2 are stacked alternately (that is, alternately arranged in an array, that is, a high-strength iron core punch 1 is pressed together next to a low-leakage magnetic core punch 2), Place the permanent magnet 3 in the permanent magnet groove 101 of the high-strength iron core punch 1 and the low-leakage magnet core punch 2,

[0053] Place the end plate A4 and the end plate B5 on both sides of the structure formed by laminating the high-strength iron core punch 1 and the low-leakage magnetic core punch 2, and place the high-strength iron core punch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com