Three-layer tubing string injection device

An oil tubing string and a tubing string technology are applied in the field of a three-layer tubing string dispensing device, which can solve problems such as large lifting and fishing workload, and achieve the effects of improving water injection efficiency, strong practicability, and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

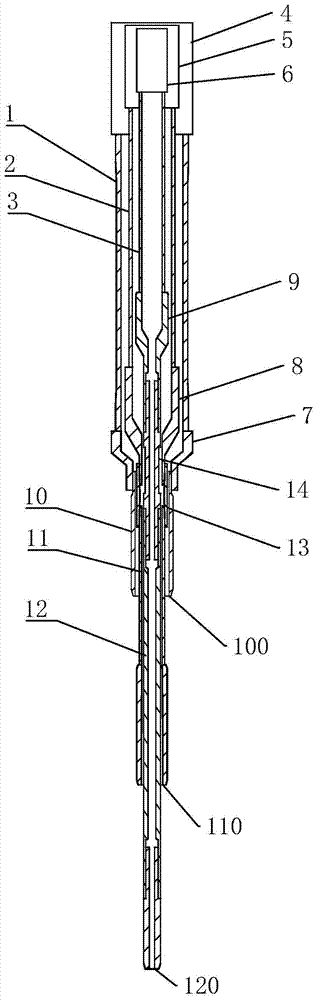

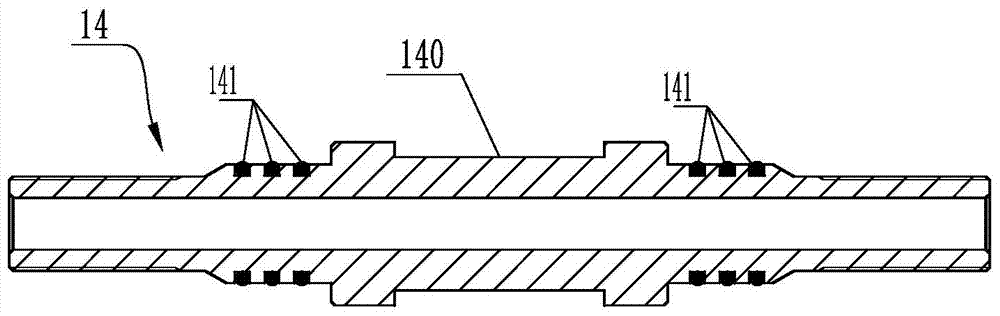

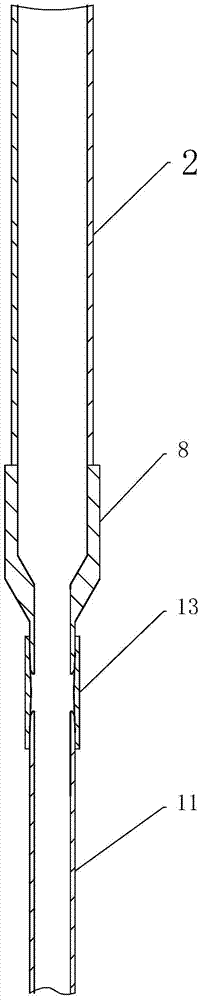

[0032] Such as Figure 1 to Figure 4 Commonly shown in the above, a three-layer tubing string dispensing device includes an outer layer string 1, an intermediate layer string 2 and an inner layer string 3;

[0033] One end of the outer layer pipe string 1 is provided with an outer layer connection assembly, the other end of the outer layer pipe string 1 is connected to the outer layer water injection pipe 10 through the outer layer reducing joint 7, and one end of the middle layer pipe string 2 is provided with an intermediate layer connection assembly, The other end of the middle layer pipe string 2 is connected to the middle layer water injection pipe 11 through the middle layer reducing joint 8, one end of the inner layer pipe string 3 is provided with an inner layer connection assembly, and the other end of the inner layer pipe string 3 is passed through the inner layer reducing joint 9 connect the inner layer water injection pipe 12. The above-mentioned outer layer conne...

Embodiment 2

[0064] The structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in the size change of the above-mentioned pipe column, water injection pipe, and water injection port at the end of the water injection pipe, as follows:

[0065] Outer tubing string 1: use tubing with an outer diameter of 96.84mm and a large inner diameter, with an inner diameter of 85mm;

[0066] The outer gap connecting hoop 4 adopts a 3-1 / 2EU small gap oil pipe coupling, and the outer diameter of the outer gap connecting hoop is 116mm;

[0067] Outer water injection pipe 10: oil pipe with an outer diameter of 58 mm and an inner diameter of 47 mm. The outer water injection pipe 10 is connected to the outer pipe column through an outer variable diameter joint, and the inner diameter of the water injection port 100 at its end is 47 mm.

[0068] Middle layer tubing string 2: use tubing with an outer diameter of 62mm and an inner diameter of 54mm;

[0069] 2-3 / 8NU small-g...

Embodiment 3

[0077] The structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in the size change of the above-mentioned pipe column, water injection pipe, and water injection port at the end of the water injection pipe, as follows:

[0078] Outer tubing string 1: use tubing with an outer diameter of 92mm and an inner diameter of 79mm;

[0079] The outer gap connecting hoop 4 adopts a 3-1 / 2EU small gap oil pipe coupling, and the outer diameter of the outer gap connecting hoop is 105mm;

[0080] The outer layer water injection pipe 10: the outer diameter is 54 mm, the inner diameter is 43 mm, connected to the outer layer pipe string 1 through the outer layer variable diameter joint 7, and the inner diameter of the water injection port 100 at the end is 43 mm.

[0081] Middle layer tubing string 2: oil pipe with an outer diameter of 59.53mm and an inner diameter of 49mm;

[0082] 2-3 / 8NU small-gap tubing couplings are adopted for the middle layer gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com