Gas desorption instrument

A desorption and gas technology, applied in the direction of instruments, analytical materials, etc., can solve the problems of water shortage, large water consumption, and fragile measuring tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

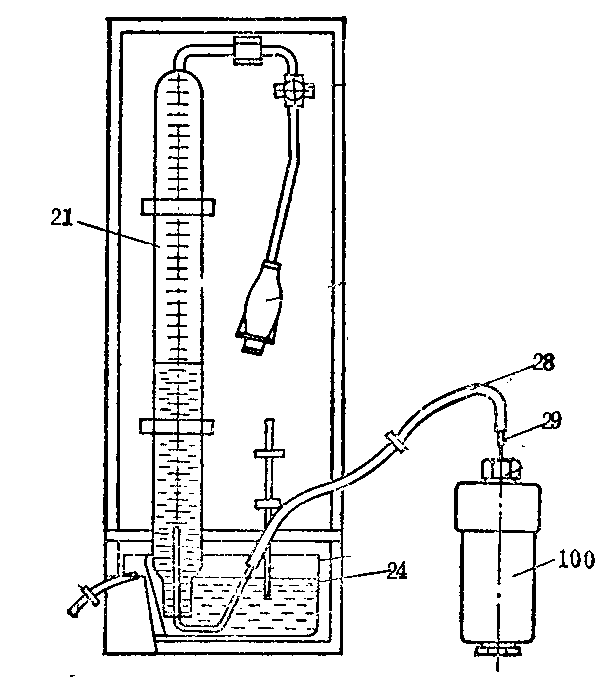

Embodiment 1

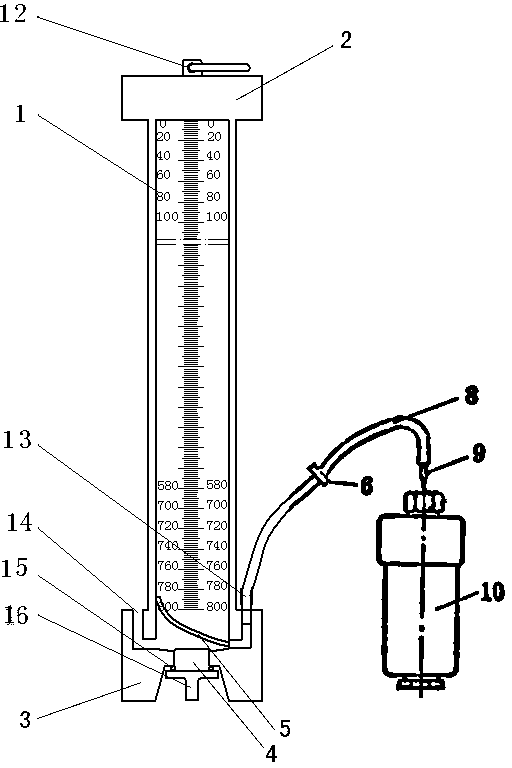

[0015] like figure 2 As shown, the gas desorption instrument of this embodiment includes a measuring tube 1, an exhaust rubber hose 8 and a puncture needle 9. The top end of the measuring tube 1 is provided with an upper cover 2, and a lifting ring 12 is installed on the upper cover 2. The measuring tube The bottom end of 1 is provided with a base 3, the middle part of the base 3 is provided with a water inlet 4, the water inlet 4 is provided with a plug 16, and a sealing ring 15 is arranged between the plug 16 and the water inlet 4, between the base 3 and the measuring tube 1 A drain 14 is formed between them, and the drain 14 communicates with the lower part of the measuring tube 1 in the form of a "U"-shaped pipe. A hose 5 is arranged inside the measuring tube 1 , and an air inlet 13 is opened on the base 3 , and the air inlet 13 communicates with the measuring tube 1 through the connecting hose 5 . There is a scale on the measuring tube 1. The hose 5 is connected to the...

Embodiment 2

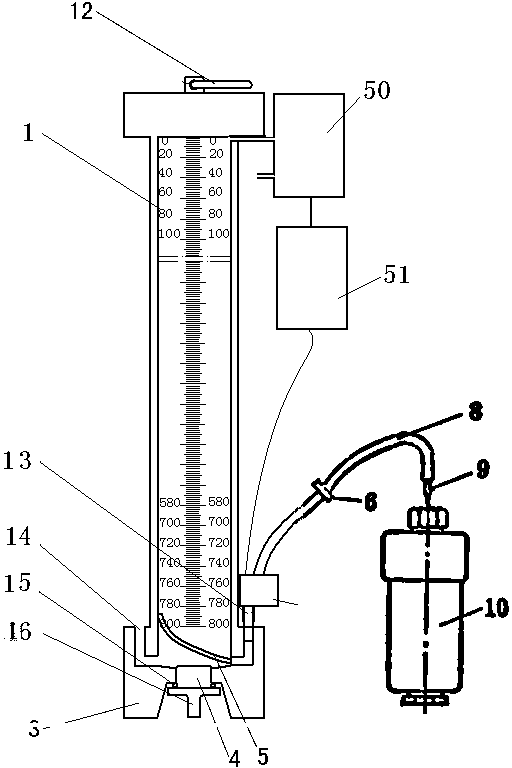

[0019] like image 3 As shown, the gas desorption instrument of this embodiment includes a measuring tube 1, an exhaust rubber hose 8 and a puncture needle 9. The top end of the measuring tube 1 is provided with an upper cover 2, and a lifting ring 12 is installed on the upper cover 2. The measuring tube The bottom end of 1 is provided with a base 3, the middle part of the base 3 is provided with a water inlet 4, the water inlet 4 is provided with a plug 16, and a sealing ring 15 is arranged between the plug 16 and the water inlet 4, between the base 3 and the measuring tube 1 A drain port 14 is formed in between, a hose 5 is arranged in the measuring tube 1, an air inlet 13 is opened on the base 3, a solenoid valve 52 is installed on the air inlet 13, and the air inlet 13 connects with the exhaust rubber hose through the solenoid valve 52 8 are connected, the exhaust rubber hose 8 is connected with the coal sample tank 10 through the puncture needle 9, and the spring clip 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com