Improvement system for severely salinized soil

A salinization and soil technology, which is applied in the direction of soil improvement machinery, applications, chemical instruments and methods, can solve the problems of long control period, salt waste, and low soil improvement efficiency, so as to improve the efficiency of soil improvement and strengthen the barrier effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

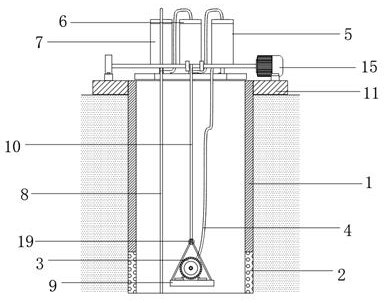

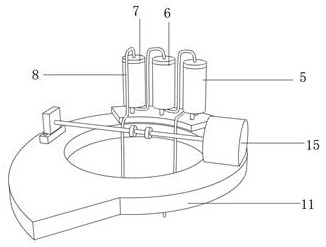

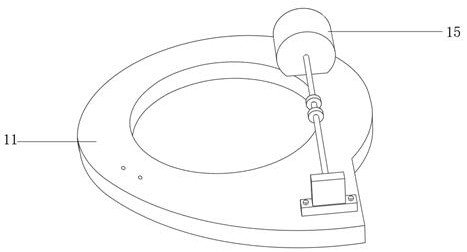

[0033]ReferFigure 1-7 A modified system for severe salinized soil, including up and down settings, the solid shaft 1 and the tube shaft 2 in the soil, and the tube shaft 2 is provided with an internal circulation mechanism, and the upper port is provided at the upper port. The circulatory mechanism is surrounded by a peripheral ring 11 on the upper portion of the actual pipe shaft 1, and the outer cycle mechanism is connected to the peripheral ring 11, and the outer circulating mechanism includes an filtered tank 5, a mixing tank 6 and an evaporative tank 7, an internal circulation mechanism. The water pump 3 is included, and the water pump 3 is fixed to the lower end of the filter tank 5, and the upper end of the filter tank 5 is fixed by the lower end of the water pipe and the mixing tank 6, and the upper end of the mixing tank 6 is fixed by the lower end of the water pipe and the evaporation tank 7. Connecting, the upper end of the evaporation tank 7 is fixedly connected to the c...

Embodiment 2

[0040]ReferFigure 1-3One severe salinized soil is improved, this embodiment is connected to the first embodiment, and the servo motor 15 is connected to the peripheral ring 11, and the output terminal of the servo motor 15 is fixedly connected to the reel, the canister is connected. There is a traction rope 10, and the lower end of the water pump 3 is fixedly coupled with a weight seat 9, and the lifting seat 9 is connected to the lanyard, and the lanyard and the traction rope 10 are fixed to the lower end of the ladle 19, which is convenient for the water pump 3 height. Flexible adjustment, it is convenient for the pick-up of the water pump 3, and the lower end of the servo motor 15 is rotated between the peripheral ring 11, facilitating the moving ribbon, thereby facilitating the workers underwell operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com