Oil riser bleeder

A technology of oil drainer and oil lifting pipe, which is applied in wellbore/well components, earthwork drilling, sealing/package, etc. It can solve accidents caused by oil drainer opening and draining, and slips cannot be radially opened, etc. problem, to achieve the effect of high job success rate and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

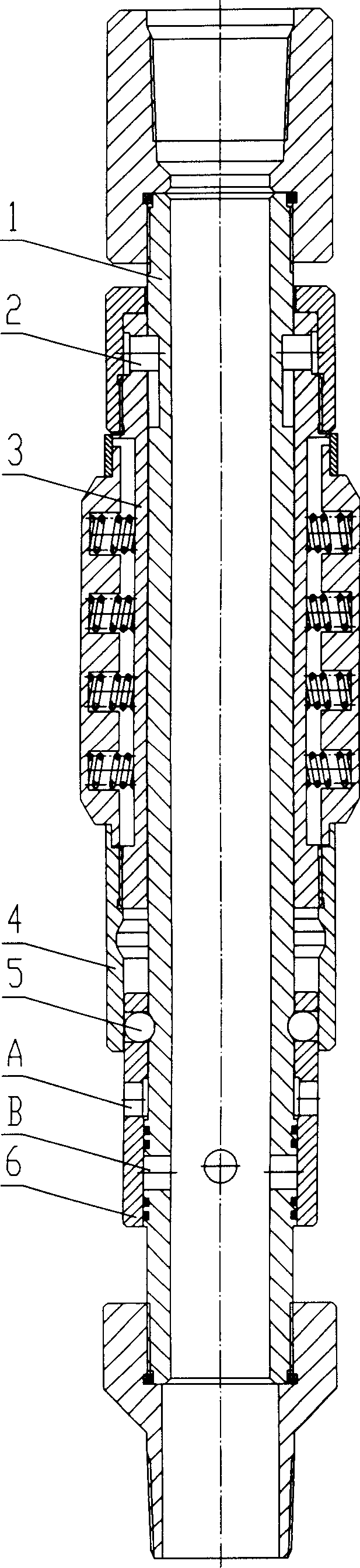

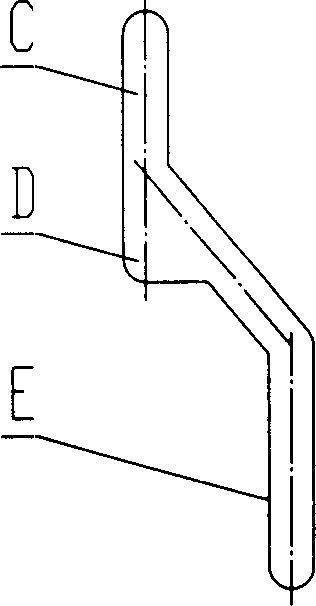

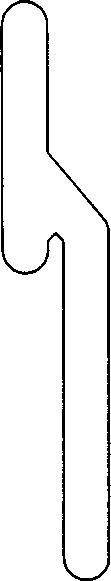

[0010] In the figure: 1 is an inner tube, 2 is a track pin, 3 is a friction mechanism, 4 is a release sleeve, 5 is a locking ball, and 6 is a sealing sleeve. Namely the present invention is made up of inner tube 1, track pin 2, friction mechanism 3, release sleeve 4, lock ball 5, sealing sleeve 6. The friction mechanism 3 is set outside the inner tube 1, and the outer surface of the inner tube 1 has a track groove, and the track groove is divided into an upper track groove C (or a short track groove, Figure 5 shown) and lower track E (or long track slot, Figure 5 As shown), the inner tube 1 and the friction mechanism 3 are connected by the track pin 2, the track pin 2 can move in the track groove on the outer surface of the inner tube 1, the release sleeve 4 is located at the lower part of the friction mechanism 3, and the sealing sleeve 6 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com