Automatic robot refueling device and refueling method

A technology of robot and driving device, which is applied in distribution device, special distribution device, liquid distribution, conveying or transfer device, etc., which can solve the problem of high precision range control of refueling vehicles and low coordination accuracy of refueling gun and fuel tank port. , small operating radius and other issues, to reduce the waiting time for refueling, improve the success rate of operation, and reduce the effect of cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

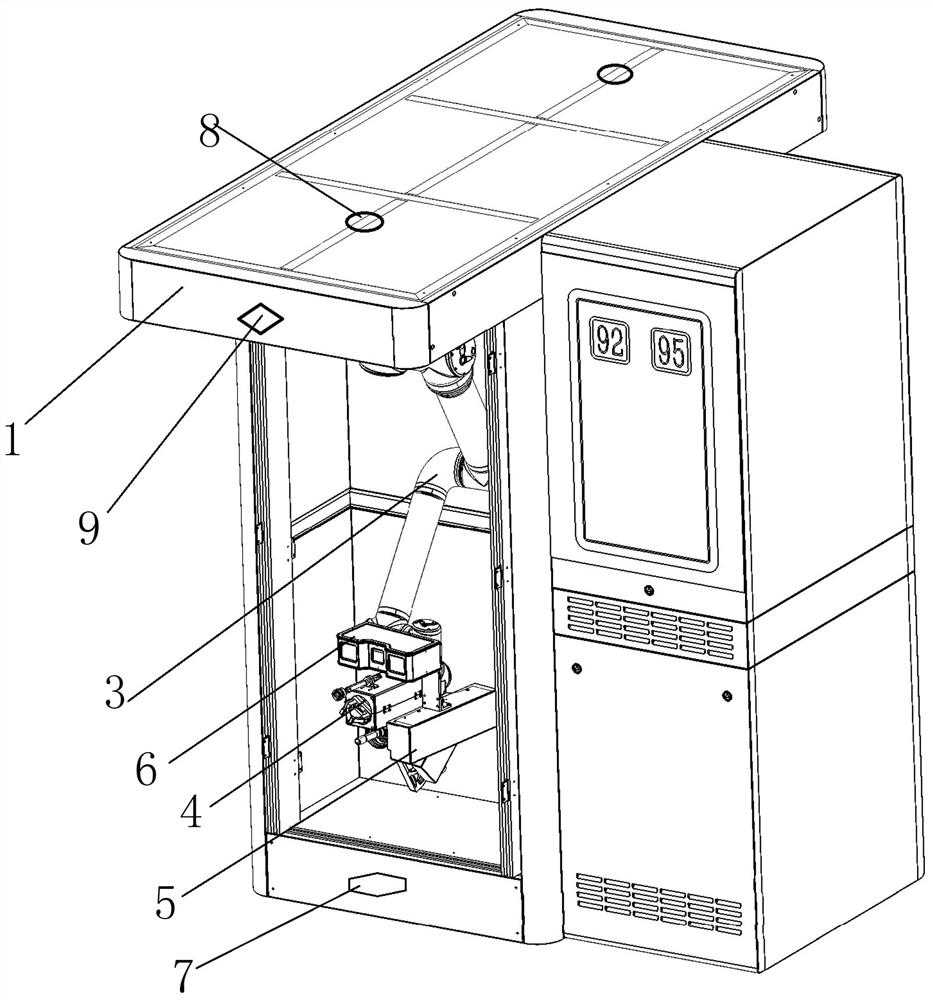

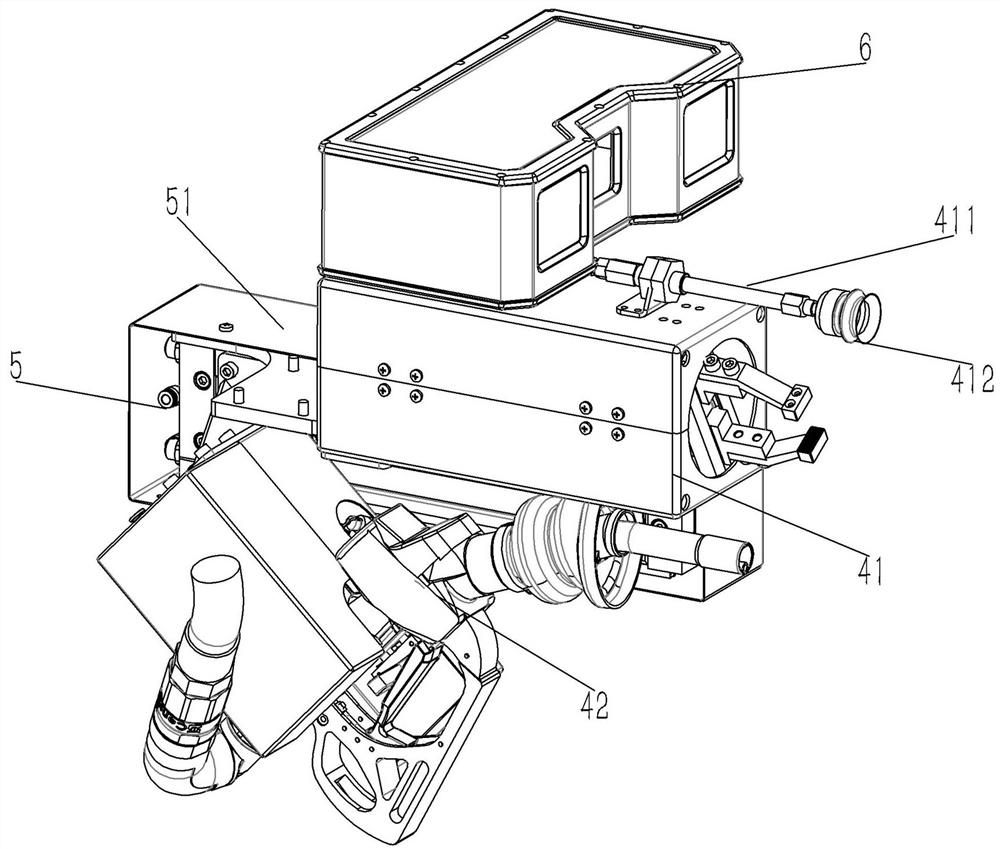

[0036] Embodiment 1: a kind of automatic robot refueling machine, see figure 1, including a mobile base 2 arranged on the top of the installation cabinet 1, a mechanical arm 3 connected to the mobile base 2 with a plurality of rotating joints, and a refueling mechanism 4 fixedly installed at the other end of the mechanical arm 3 ; The installation cabinet 1 is provided with a panel that can be opened and closed automatically, which can be opened automatically when the car is filled, so that the mechanical arm 3 can work normally; when the filling is completed and there is no filling task, the panel can be closed to make the machine The arm 3 is sealed in the casing to prevent dust from falling in and keep the casing clean.

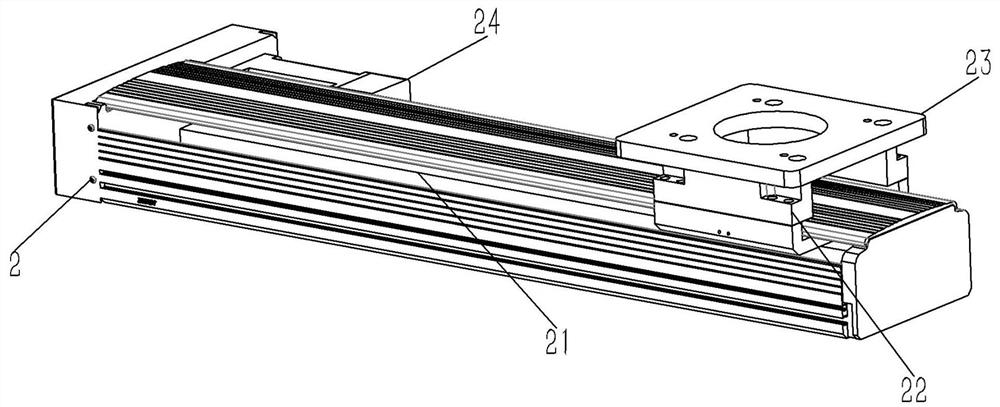

[0037] The mobile base 2, see image 3 , including a walking shaft 21 that provides a walking route for the mechanical arm 3, a base 22 that is slidably mounted on the walking shaft 21, a mounting column 23 that is fixedly connected to the base 22, and a ...

Embodiment 2

[0045] Embodiment 2, a kind of automatic robot refueling device, see Figure 7 , including the above-mentioned automatic robot refueling machine arranged symmetrically on both sides, which can meet the demand for refueling on both sides at the same time, greatly improving the filling efficiency; at the same time, the automatic robot refueling machine set on both sides can meet the refilling requirements of different types of car refueling tank positions, When refueling, the customer does not need to turn the car back and forth to meet the position of the refueling muzzle, which greatly improves the satisfaction of the customer's refueling process; Protection module 9.

[0046] The automatic fire extinguishing module 8 sends an alarm signal to the refueling operation control system after the temperature and smoke detectors installed inside the installation cabinet 1 detect temperature and smoke when a fire occurs in the installation body, and the refueling operation control sys...

Embodiment 3

[0048] Embodiment 3, an automatic refueling method, implemented based on the above-mentioned automatic robot refueling device, comprising the following steps:

[0049] S1. Install a vehicle entry guidance system at the entrance of the gas station. The system can identify the vehicle type and judge whether the fuel port of the vehicle type is on the right or left side, and accordingly guide the vehicles to achieve both sides. Carry out gasoline filling work, improve the space utilization rate of gas stations and increase the efficiency of automatic refueling of cars.

[0050] S2, after the driver stops the car, the ranging sensor 7 judges the distance and angle of parking, and the judgment result is sent to the control system of the automatic refueling robot, and the control system controls the mobile base 2 and the mechanical arm 3 fixed on the mobile base 2 Position adjustment control is performed so that the refueling mechanism 4 arranged at the end of the mechanical arm 3 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com