Bulldozer

A bulldozer and bulldozer shovel technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. Good performance, improve transmission fluency, and improve the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

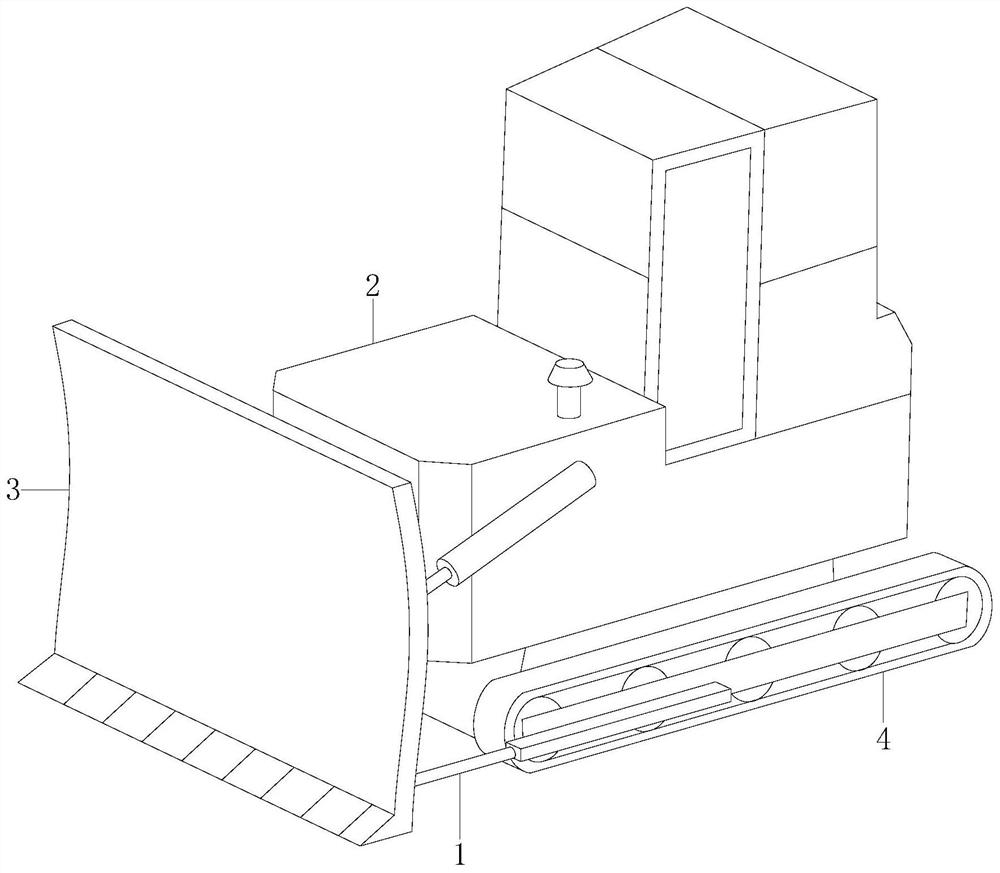

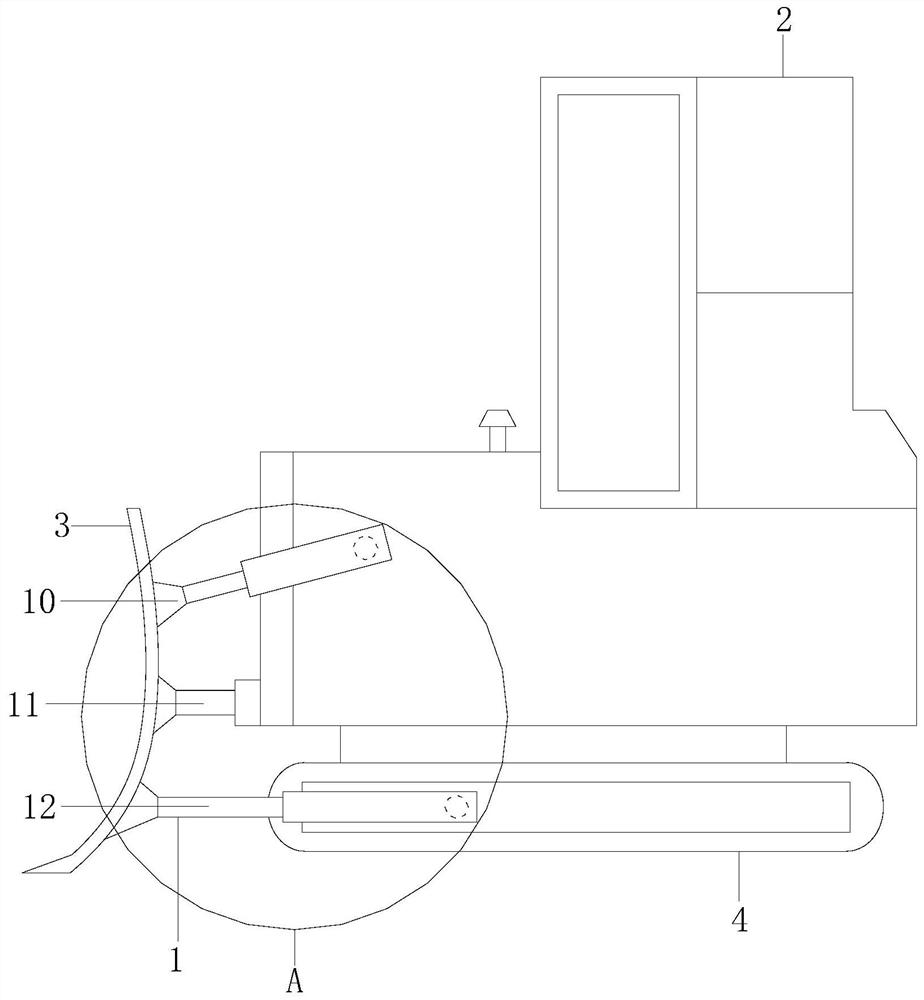

[0025] Example 1 see figure 1 , 2 , the present invention provides a bulldozer technical solution: its structure includes a connection device 1, a fuselage 2, a bulldozer blade 3, and a road wheel 4, and the bulldozer blade 3 is connected to the body 2 and the road wheel 4 through the connection device 1 , the traveling wheel 4 is installed on the fuselage 2, the connecting device 1 is composed of a cylinder 10, a fulcrum structure 11, and a buffer structure 12, and the cylinder 10 cooperates with the buffer structure 12 to form a driving force and a pushing buffer force , the cylinder 10 is installed on the fuselage 2, the fulcrum structure 11 is locked on the fuselage 2, the fulcrum structure 11 realizes slight turning of the bulldozing blade 3, and the slow support structure 12 is installed on the road wheel 4 on.

[0026] The equipment drives the bulldozing blade 3 to bulldoze and shovel soil through the connection device 1, the cylinder 10 cooperates with the buffer su...

Embodiment 2

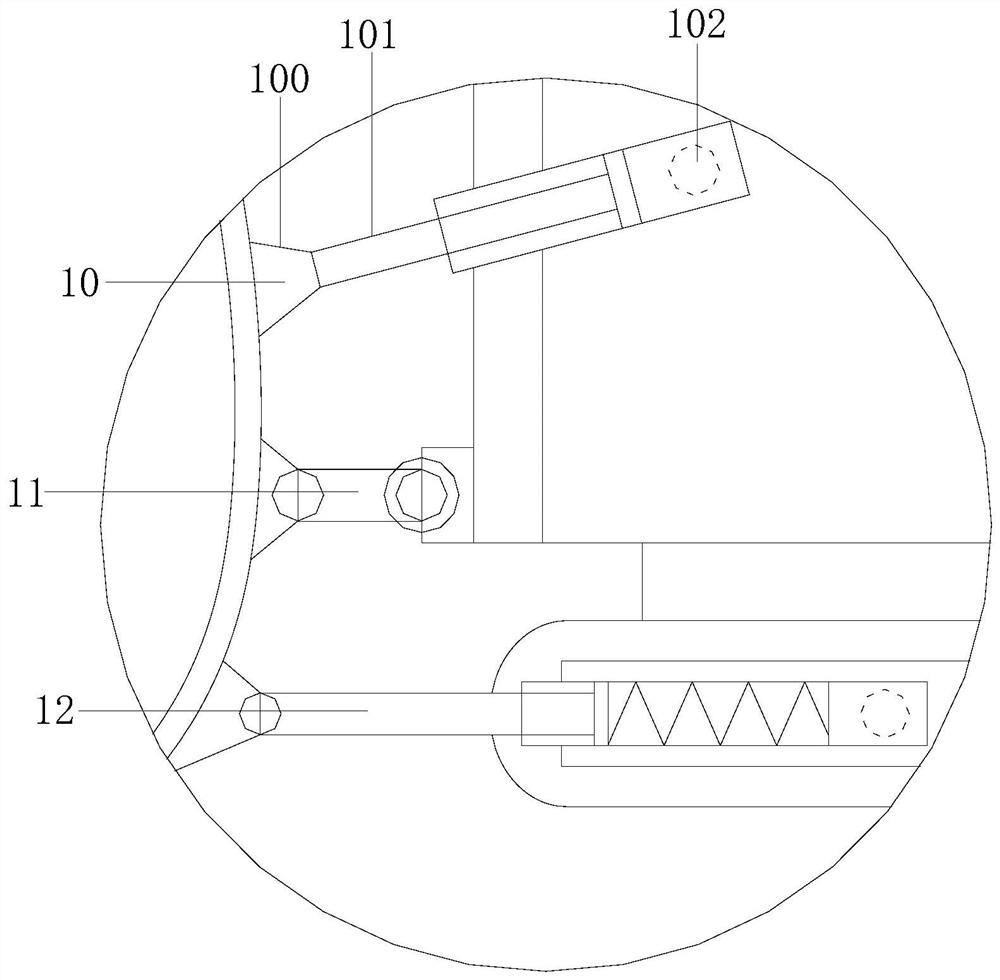

[0027] Example 2 see Figure 3-6 , the present invention provides a bulldozer technical solution: the structure of the cylinder 10 includes a cylinder body cover 100, a cylinder body 101, a cylinder body shaft 102, the cylinder body cover 100 is installed on the cylinder body 101, and the cylinder The main body 101 is equipped with a cylinder housing shaft 102, and the shaft structure 11 includes a shaft housing cover 110, a shaft support rod 111, and a support lock frame 112. Frame 112 is installed and connected, and the support shaft support bar 111 includes double rotating shaft 1110, transmission pulley 1111, main rod body 1112, motor 1113, and described driving pulley 1111 is installed on the double rotating shaft 1110, and described main rod body 1112 is connected with double rotating shaft 1110, The motor 1113 is installed and connected, and the double rotating shaft 1110 is installed and connected to the motor 1113 and both are electrically connected. The double rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com