Transmission fine adjustment light chain plate assembly line type discharging and forming integrated equipment

An assembly line, fine-tuning technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as edge extrusion, damaged parts, and material scrapping, and achieve the effects of increasing yield and reducing offset and processing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

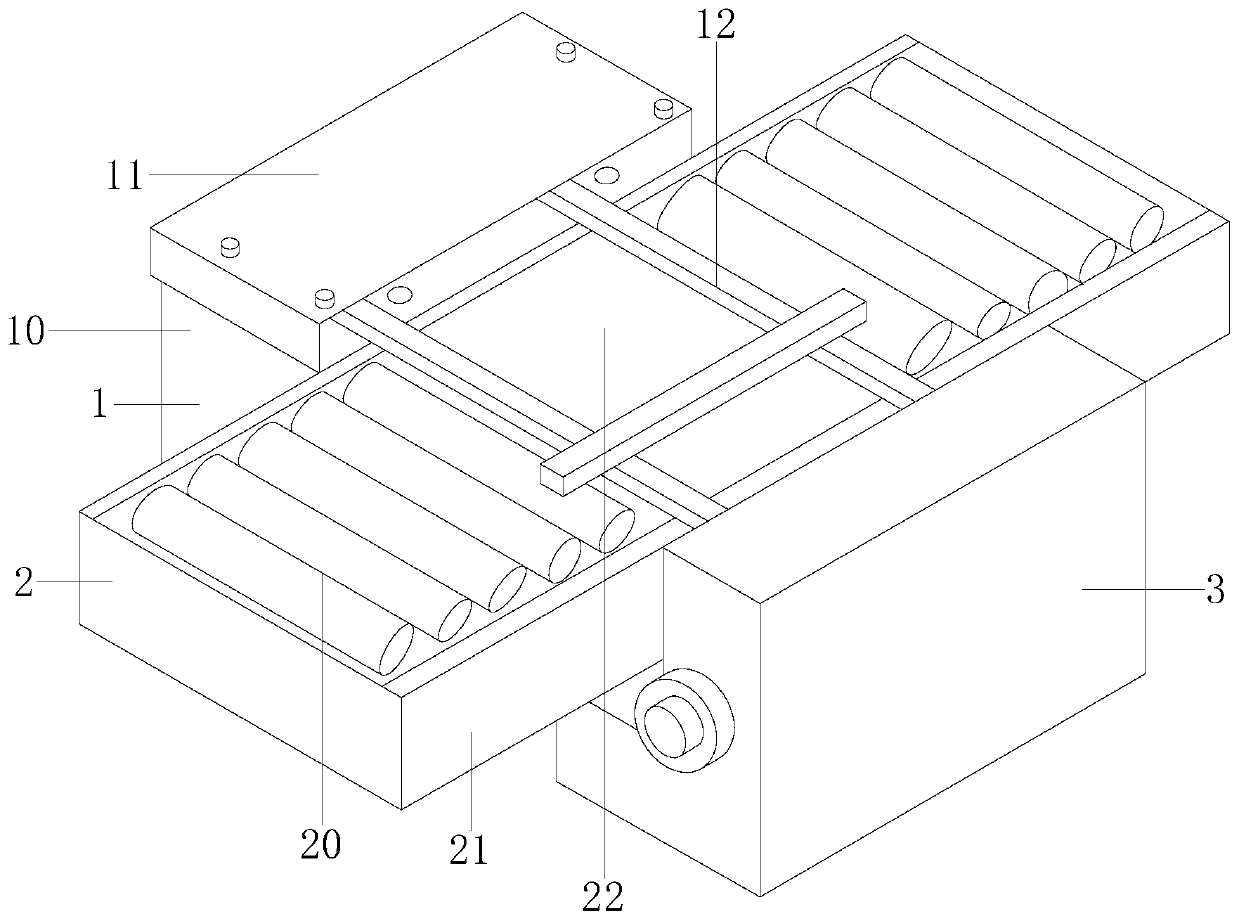

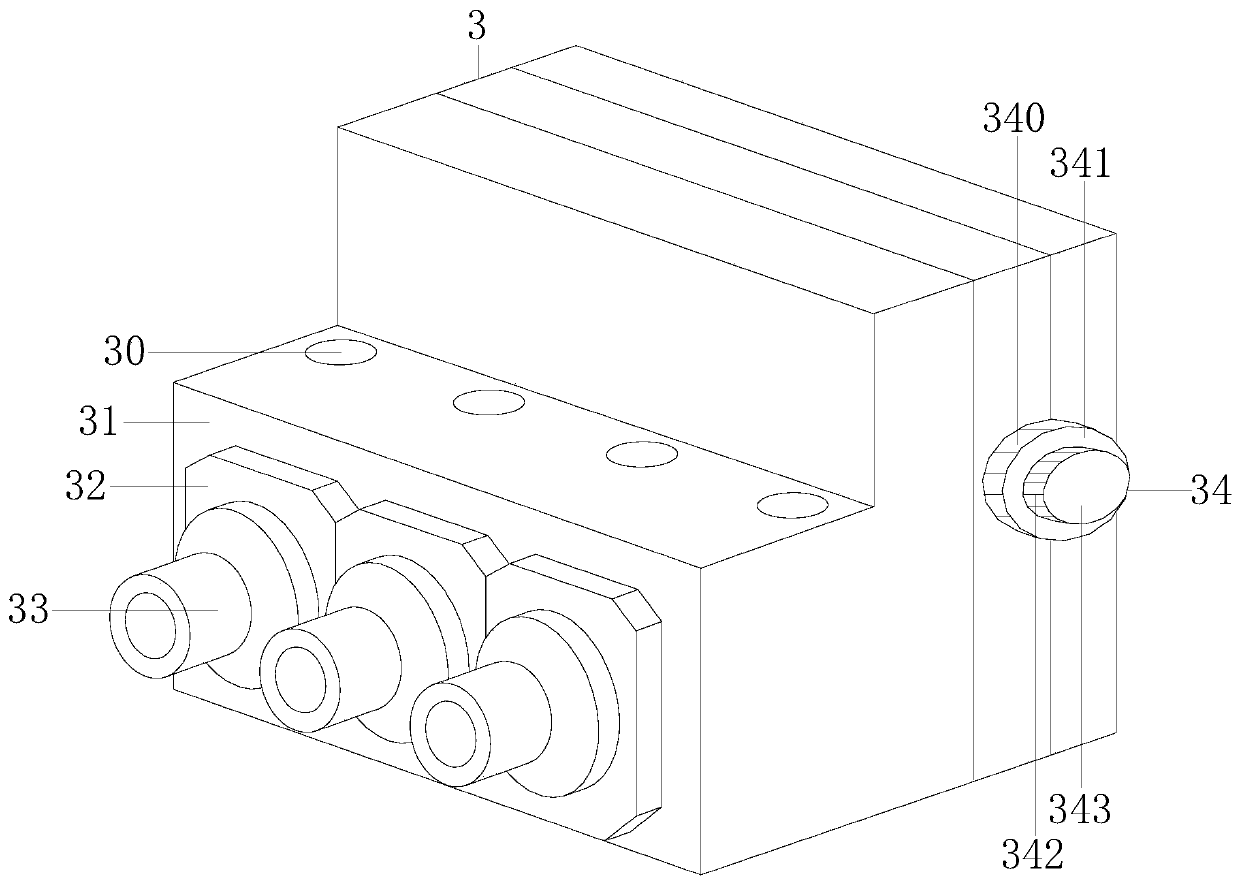

[0026] Example 1 see Figure 1-3 , the present invention provides a technical solution for a transmission micro-adjustment light-duty chain plate assembly line discharge forming integrated equipment: its structure includes a forming installation frame 1, a conveying assembly line 2, and a forming transmission frame 3, the conveying assembly line 2 and the forming assembly assembly 1, The forming transmission frame 3 is locked, and the forming installation frame 1 is installed and connected with the forming transmission frame 3. The forming installation frame 1 and the forming transmission frame 3 cooperate with the transmission to press and form the material, and the conveying and forming are integrally driven, and the transmission is flexible. The forming Mounting frame 1 is made up of mounting side frame 10, mounting plate frame 11, shaping press frame 12, described mounting side frame 10 is connected with mounting plate frame 11 by bolt, and described mounting plate frame 11...

Embodiment 2

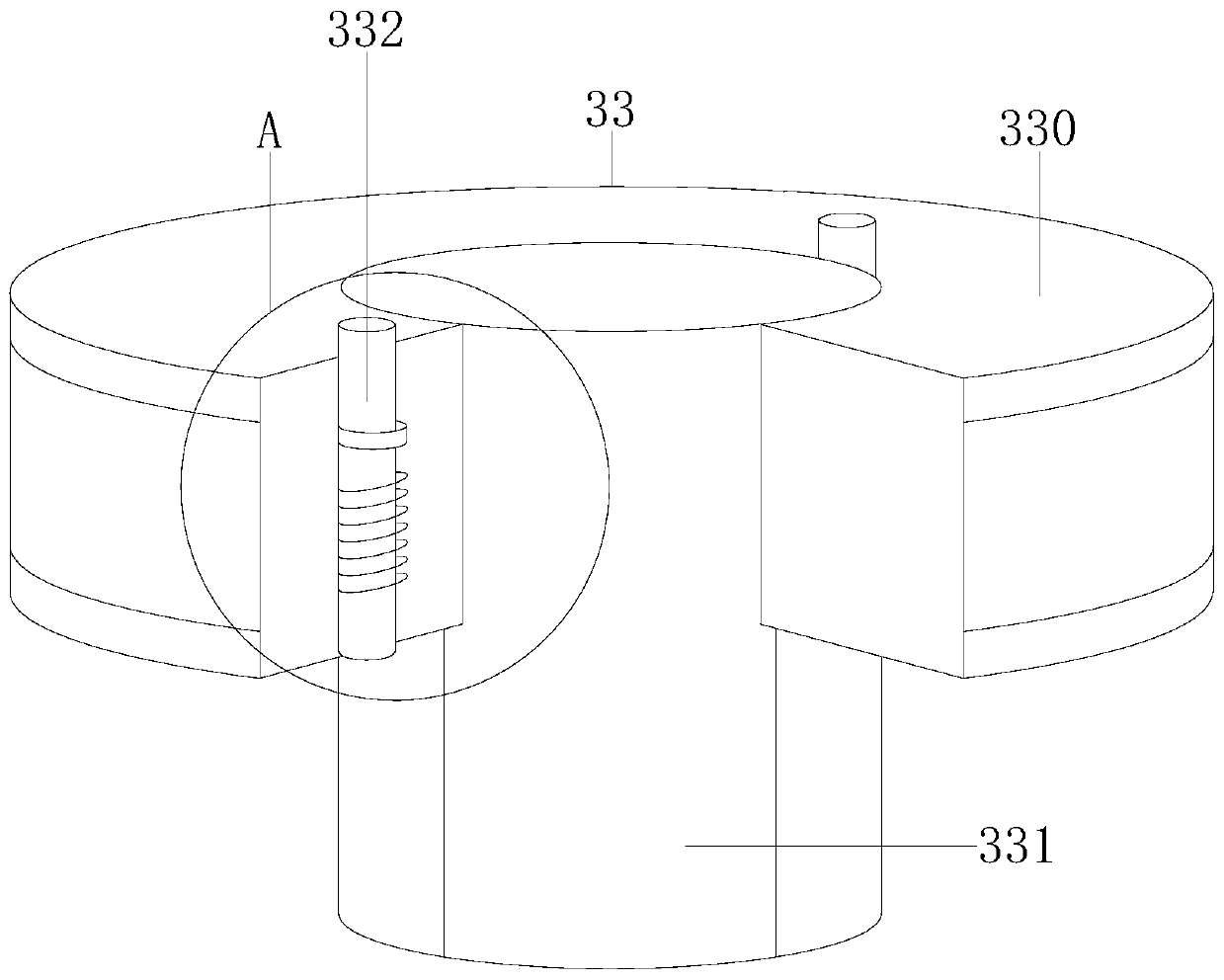

[0028] Example 2 see Figure 5-7, the present invention provides a technical solution for a transmission micro-adjustment light-duty chain plate assembly line discharge forming integrated equipment: the structure of the moving roller 30 includes a section bar 300, a connecting shaft 301, two section bars 302, three section bars 303, a card block 304, the first section rod 300 is axially connected with the connecting shaft 301, the two section bars 302 are connected with the connecting shaft 301, and the three section bars 303 through rails, the three section bars 303 are equipped with a block 304, and the connecting The rotating shaft 301 cooperates with the two section rods 302 to expand and contract, and the first section rod 300 cooperates with the joint rotating shaft 301 to rotate. The block 304 acts as a fastening reinforcement, and the overall telescopic swing is used to fine-tune the material. The one section rod 300 includes a turning shaft 3000, frame shaft 3001, hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com