Sand washing drilling and grinding fluid system for high-temperature sulfur-containing deep well

A technology for sand flushing drilling and deep wells, which is applied in earthwork drilling, wellbore/well components, drilling compositions, etc. It can solve the problems of poor temperature resistance and shear resistance, non-acid resistance Eliminate problems such as high content of permanent guar gum residue, achieve the effect of reducing corrosion, improving operation success rate, and reducing operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

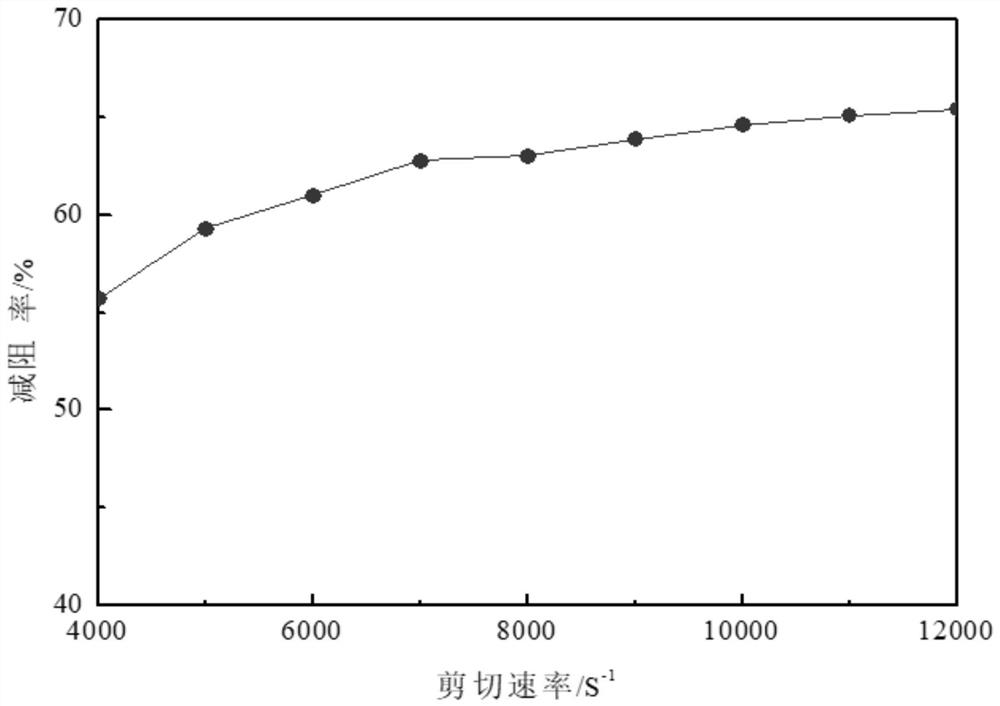

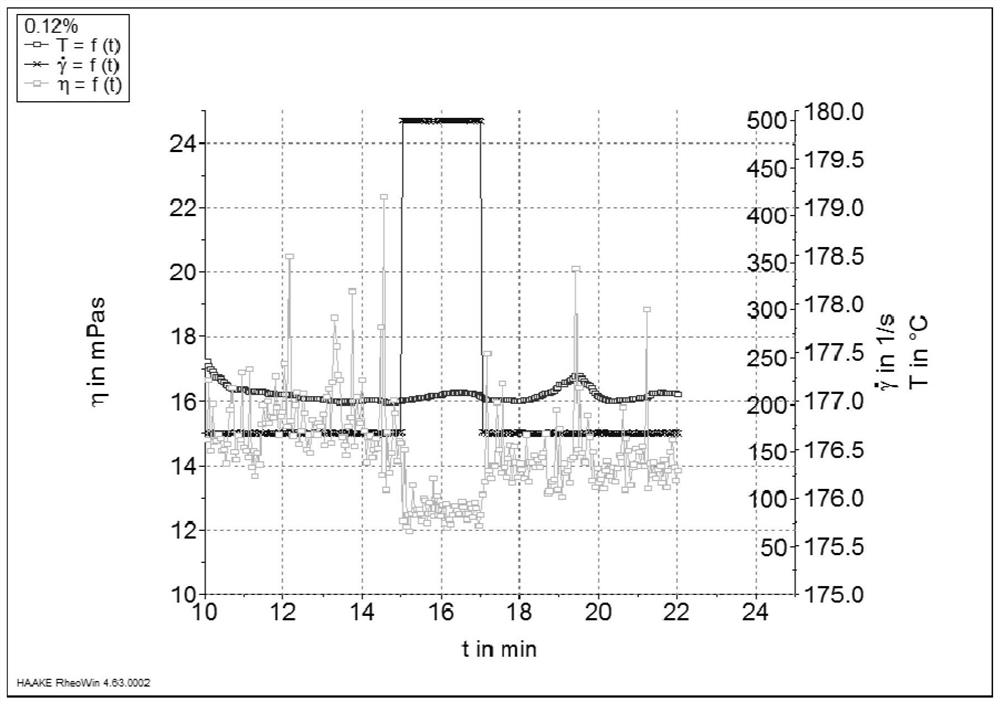

[0024] A sand washing and drilling fluid system for high-temperature sulfur-containing deep wells, wherein the sand washing and drilling fluid is prepared according to mass percentage, 99.345% of water is weighed, and 0.05% of heat-resistant polymer drag reducer, 0.2% of Fluorocarbon surfactant, 0.2% small cationic polymer clay stabilizer, 0.2% s-triazine sulfur remover, 0.005% potassium hydroxide pH regulator; the performance parameters of the system are as follows: when the line speed is 18m / s The drag reduction rate is 72%, the apparent viscosity is 9.0mPa·s, the surface tension is 24.7mN / m, the interfacial tension is 2.1mN / m, and the anti-swelling rate is 82.4%. When the hydrogen sulfide concentration is 1500ppm, the sulfur removal rate reaches 100%. pH 8.0.

Embodiment 2

[0026] A sand washing and drilling fluid system for high-temperature sulfur-containing deep wells, wherein the sand washing and drilling fluid is prepared according to mass percentage, 99.265% of water is weighed, and 0.03% of temperature-resistant polymer drag reducer, 0.3% of Fluorocarbon surfactant drainage aid, 0.2% quaternary ammonium cationic surfactant clay stabilizer, 0.2% s-triazine sulfur removal agent, 0.005% potassium hydroxide pH regulator; the performance parameters of the system are as follows: When the line speed is greater than 18m / s, the drag reduction rate is 71.5%, the apparent viscosity is 4.8mPa s, the surface tension is 23.1mN / m, the interfacial tension is 1.2mN / m, and the anti-swelling rate is 82.4%. The sulfur rate reaches 100%, and the pH value of the solution is 7.5.

Embodiment 3

[0028] A sand washing and drilling fluid system for high-temperature sulfur-containing deep wells, wherein the sand washing and drilling fluid is prepared according to mass percentage, 99.332% of water is weighed, and 0.01% of heat-resistant polymer drag reducer, 0.2% of Fluorocarbon surfactant, 0.3% small cationic polymer clay stabilizer, 0.15% modified triazine sulfur remover, 0.008% sodium hydroxide pH regulator; the performance parameters of the system are as follows: when the line speed is greater than 18m / s The drag reduction rate is 65.5%, the apparent viscosity is 1.3mPa·s, the surface tension is 23.8mN / m, the interfacial tension is 1.7mN / m, and the anti-swelling rate is 87.2%. When the hydrogen sulfide concentration is 1500ppm, the sulfur removal rate reaches 100%. The pH of the solution was 8.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com