Rotary oil draining device

A technology of inner pipe and track, which is applied in the field of rotary oil drainer, can solve problems such as accidents caused, slips cannot be opened radially, and oil drainer is opened to drain oil, etc., to achieve reliable operation, high operation success rate, and wide application range big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

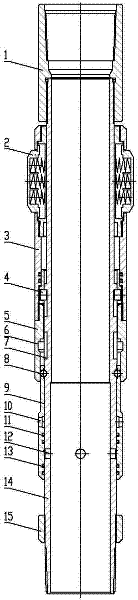

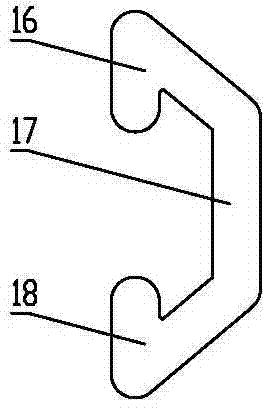

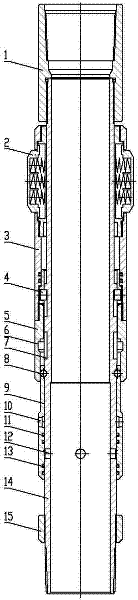

[0010] Embodiments of the present invention include an upper joint 1, a friction mechanism 2, a connecting sleeve 3, a track pin 4, a locking sleeve 5, a locking ball 8, a sealing sleeve 9, an upper sealing ring 11, a lower sealing ring 13, an inner pipe 14, and an upper joint 1 is connected to the upper part of the inner tube 14, there is a track 7 on the inner tube 14, the front end of the track pin 4 is inserted into the track on the inner tube 14, there is a lock ball groove on the inner tube 14, the oil drain hole 12 on the inner tube 14, the sealing sleeve 9 is set on the inner tube 14, the sealing sleeve 9 covers the oil drain hole 12, the upper sealing ring 11 and the lower sealing ring 13 are installed between the inner tube 14 and the sealing sleeve 9, the upper sealing ring 11 is on the oil drain hole 12, The lower sealing ring 13 is under the oil dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com