Full-automatic valve bag packaging and stacking production line

A valve bag and production line technology, applied in the field of automatic valve bag packaging and palletizing production line, can solve the problems of mechanical wear fatigue of motion precision, large production line layout structure, cumbersome program modification, etc., and achieve the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

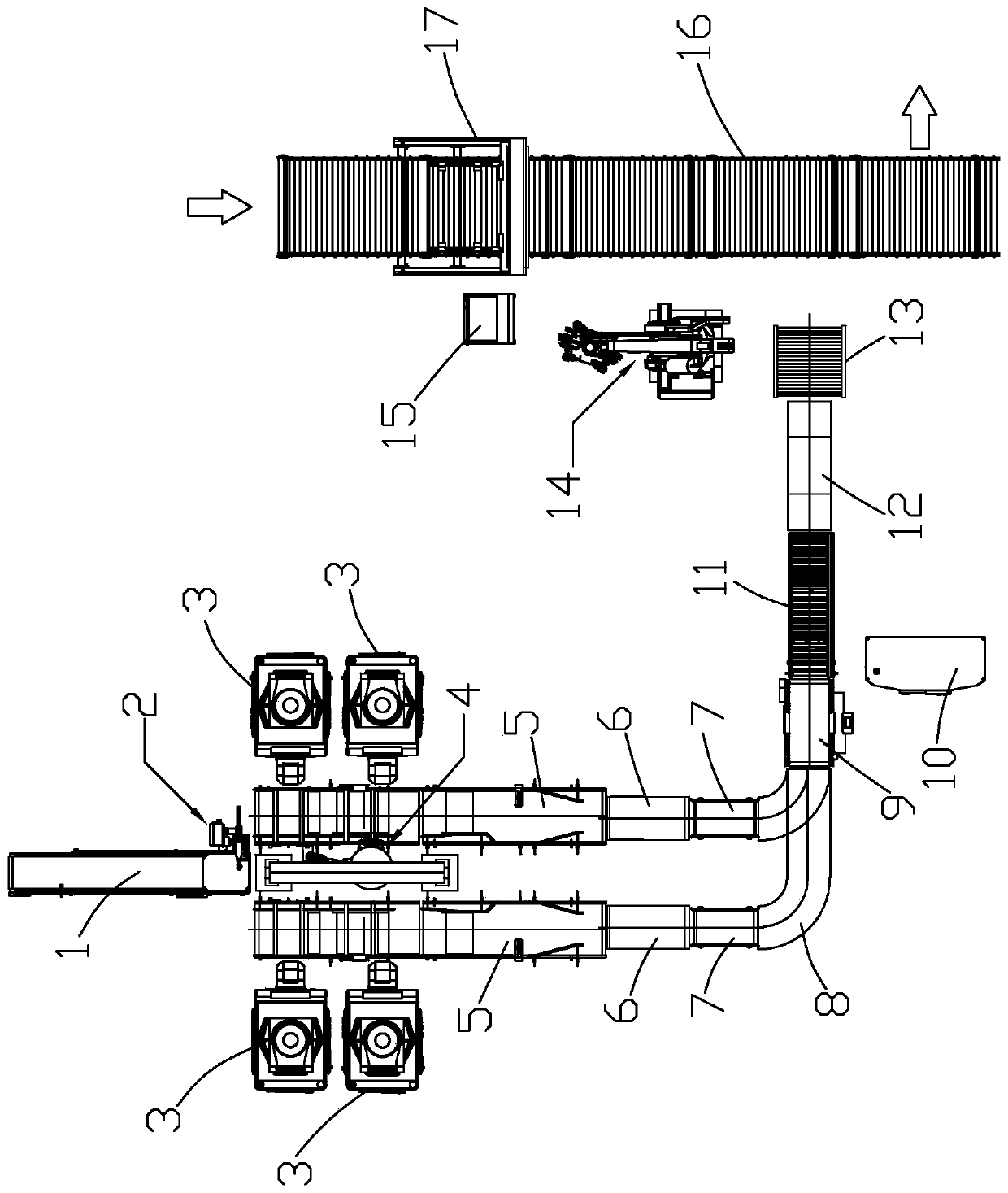

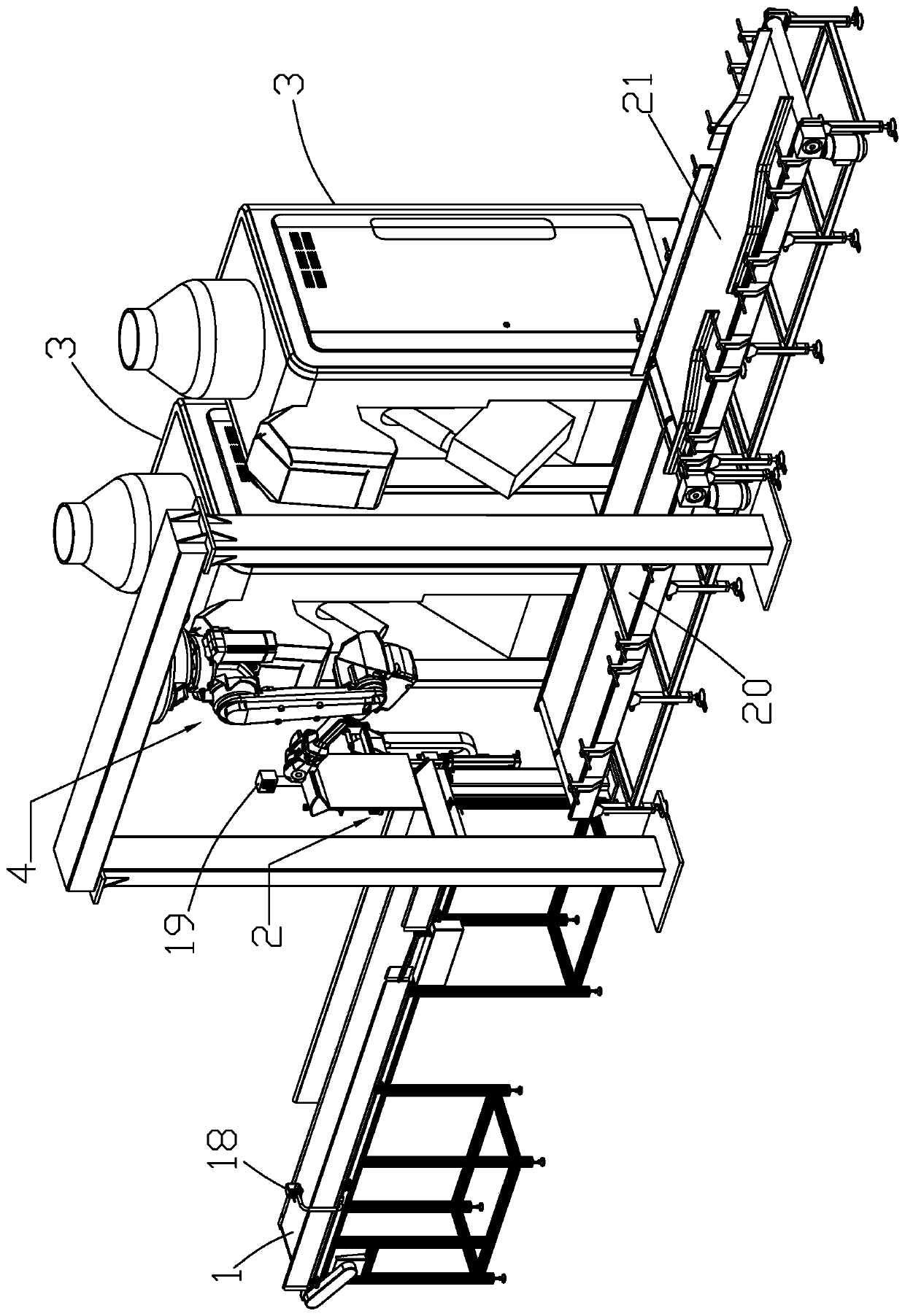

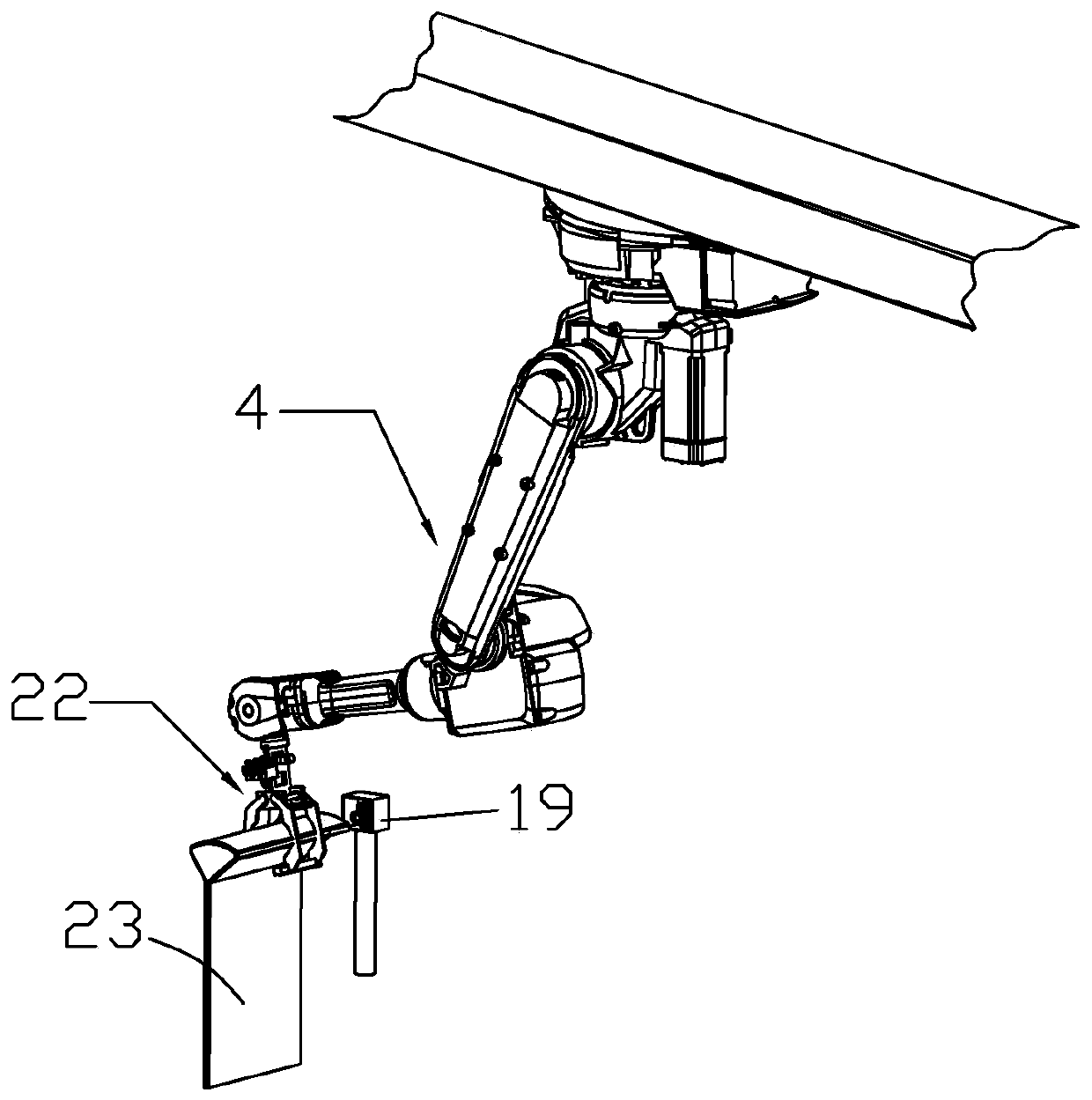

[0051] Such as Figure 1 to Figure 14 Shown is a kind of fully automatic valve bag packaging and palletizing production line of the present invention, comprising: valve bag conveying line 1, is used for conveying valve bag 23 empty bags; Main control cabinet 10, is used for controlling the work of each equipment on the whole production line; The bagging robot 4 is used for grabbing and bagging the valve pocket 23. The bagging robot 4 conforms to two-way rotation operation and 360-degree all-round work. When it is practical and practical, the bagging robot 4 is inverted on the support beam, which can leave space for the conveying line and the valve bag packaging machine 3, which is convenient for personnel to overhaul and ground activities. The bagging robot 4 grasps the valve bag 23 by the valve bag gripper 22 .

[0052] It also includes a bag stretcher 2, a valve bag packaging machine 3 and a bag drop conveying line 5. The bag stretcher 2 is located near the end of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com