In-pipe butt joint type cable control separate mining process

A docking and cable control technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to transmit electrical signals, affect the service life of cables, and cut off cables, so as to improve the success rate of operations and The effect of improving the life of cable data transmission, improving the efficiency of separate mining operations, and avoiding operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

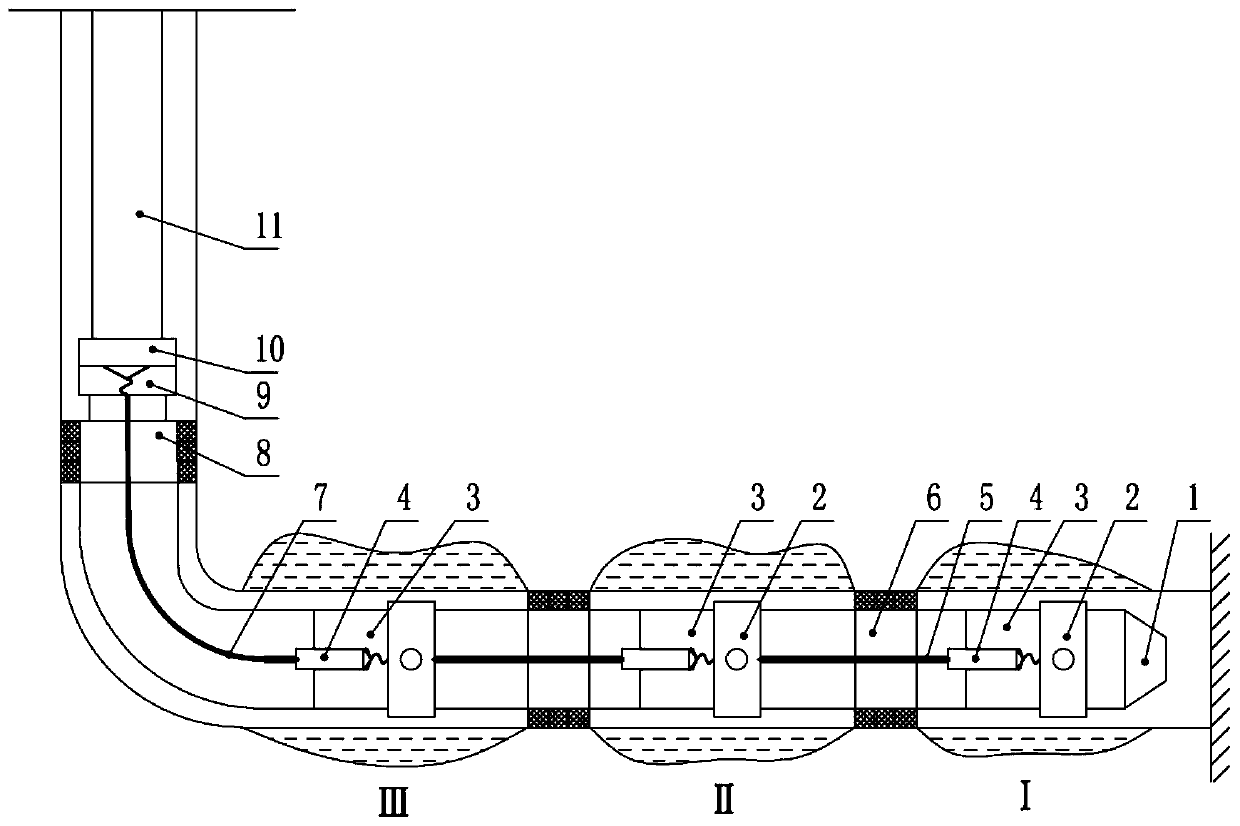

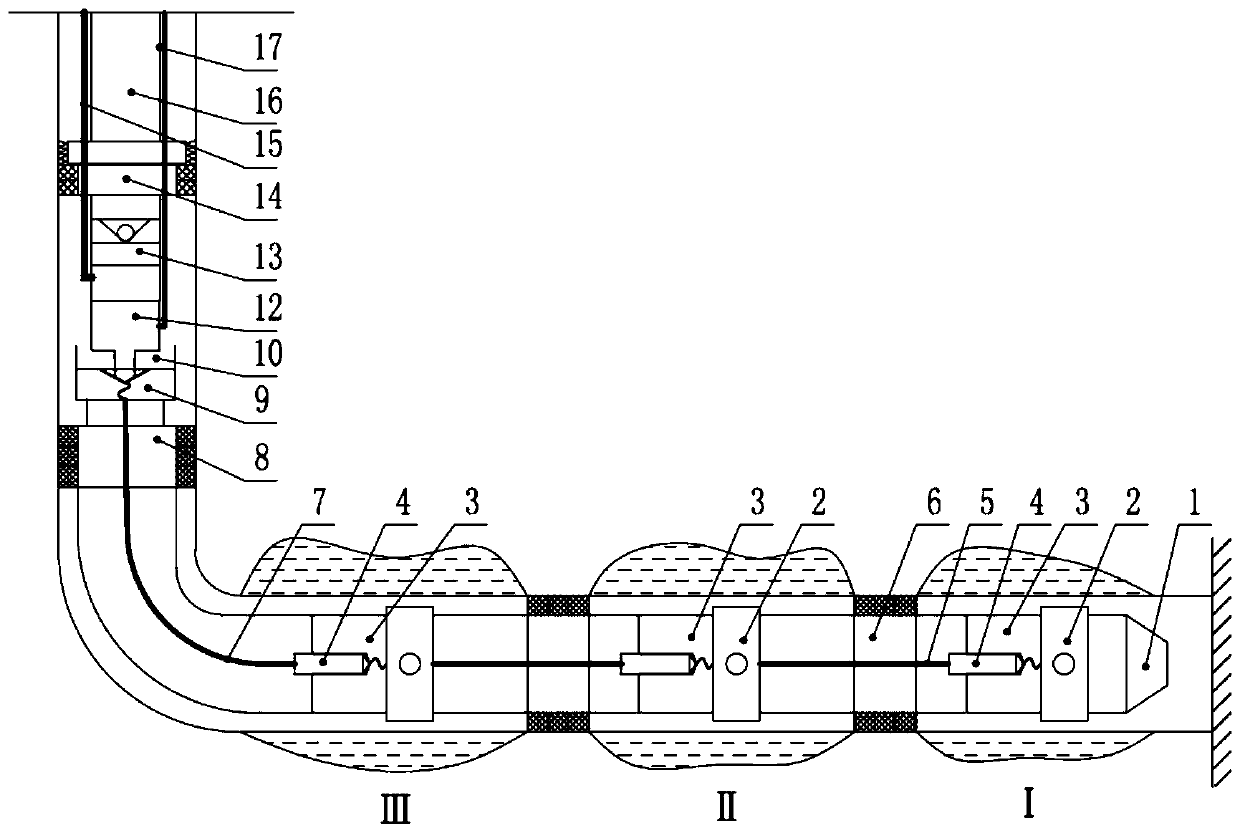

[0022] This embodiment discloses an in-pipe docking type cable-controlled separate production process. The process is realized by two trips of pipe strings. First, the lower part of the pipe string is lowered to separate the oil layers. Simultaneously control production.

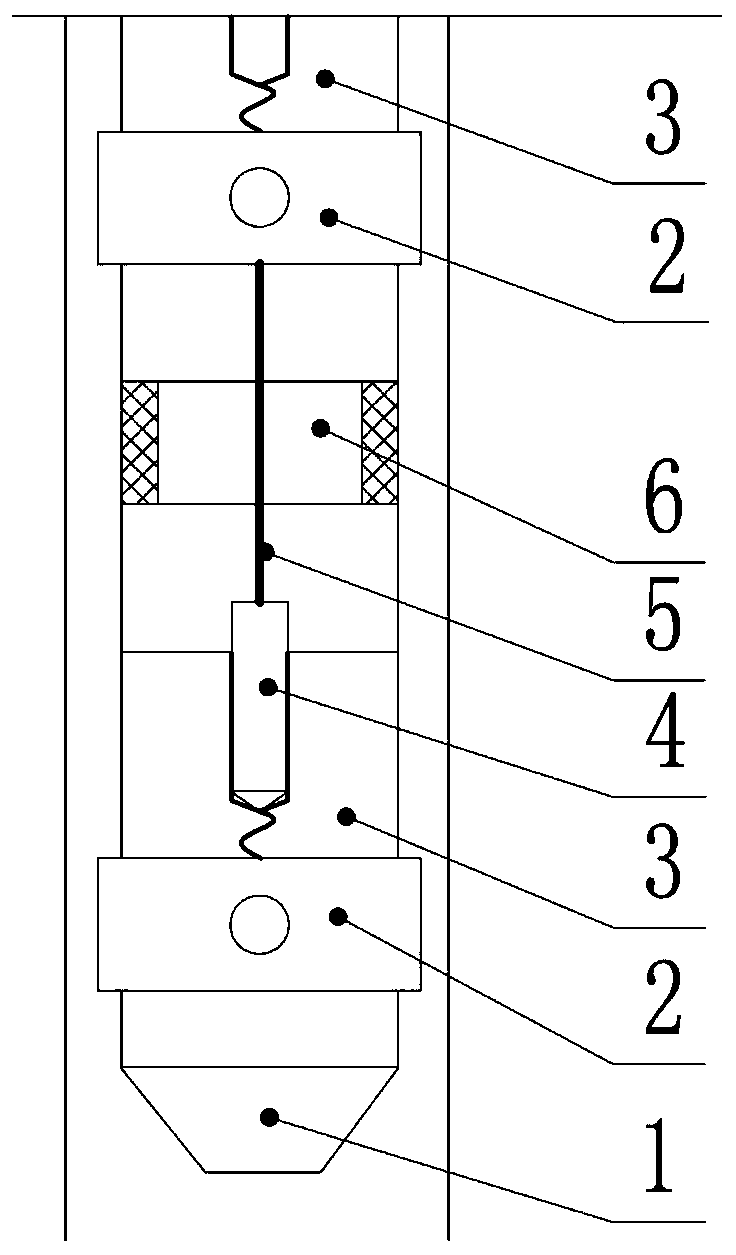

[0023] Such as figure 1 As shown, first construct the bottom section of the layered pipe string: the lowermost plug 1 is lowered, and the upper part of the plug 1 is directly connected or connected to the electric control sliding sleeve 2 through the tubing. The upper part of the electronically controlled sliding sleeve 2 and the female connector 3 are pre-connected through a quick-connect joint, sealed and insulated and tested. The upper part of the female joint 3 is dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com