Punched point anti-loosening method for sunk screw connection

A technology of countersunk head screws and punching points, applied in the directions of screws, connecting members, nuts, etc., can solve the problems of poor anti-loosening effect of connecting punching points and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

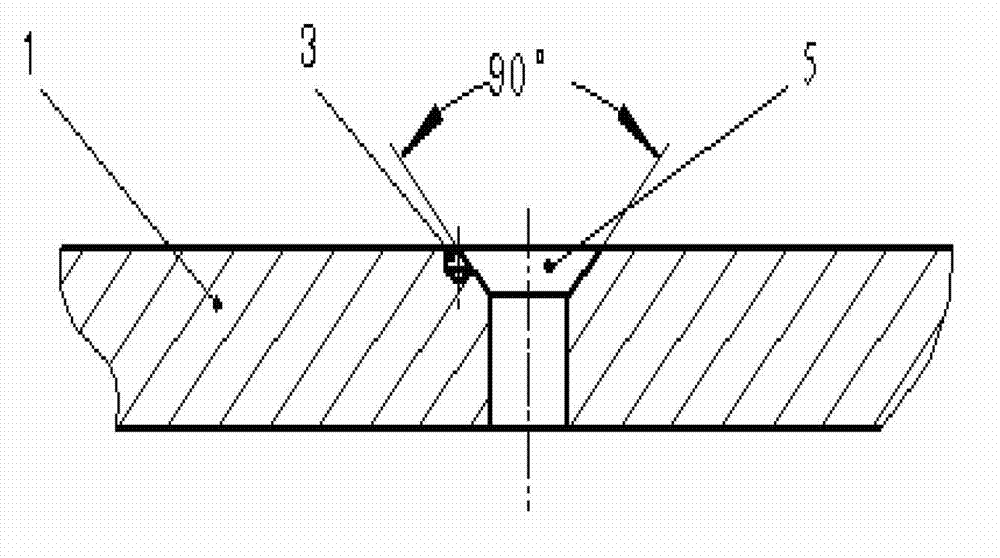

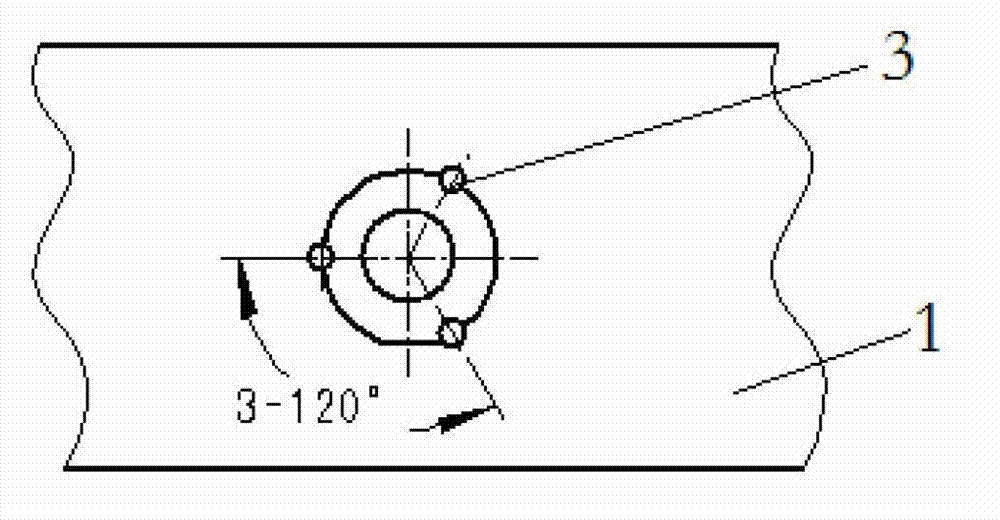

[0021] This embodiment is a punching point anti-loosening method for countersunk screw connection. The connected part 1 is a steel piece, and the connected part 1 is provided with a 90° countersunk screw hole 5 . In specific implementation:

[0022] Step 1, prefabricated punching holes. On the edge of the circumference of the countersunk screw hole 5, there are 2 to 4 circular punching holes 3 processed by machining, and the diameter of the punching holes 3 is 1.2 mm to 2.5 mm. The punching holes 3 are evenly distributed on the edge of the circumference of the countersunk screw holes 5 . The centerline of the punching hole 3 is parallel to the centerline of the countersunk screw hole 5 . In this embodiment, there are three punching holes 3; the diameter of the punching holes is 2 mm, and the depth is 1.5 mm.

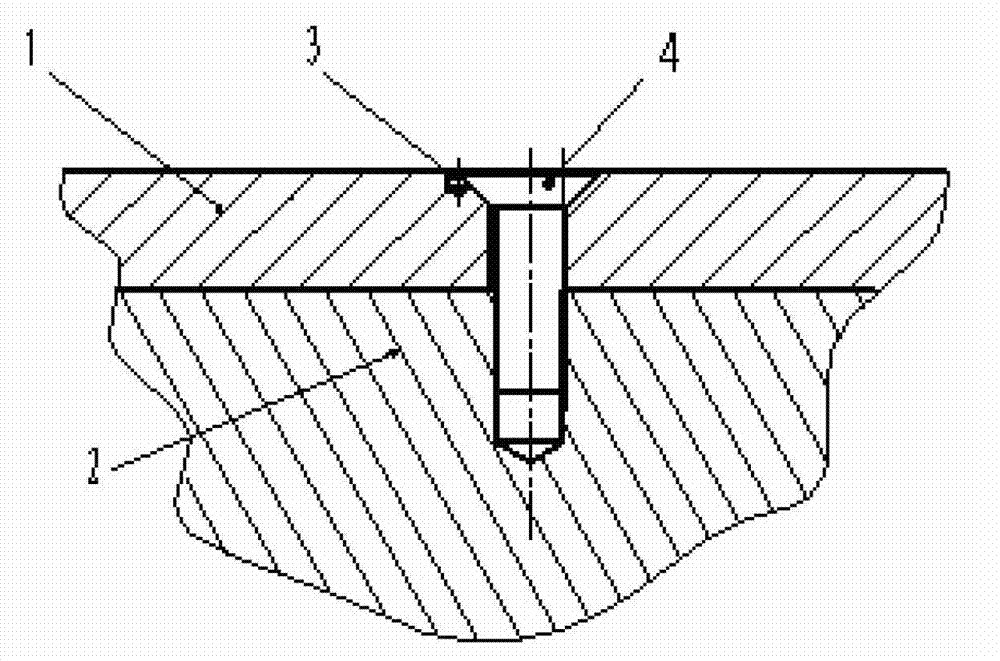

[0023] Step 2, assemble the connectors. Align the countersunk screw hole 5 on the connected part 1 with the countersunk screw hole on the product base 2 . Insert th...

Embodiment 2

[0026] This embodiment is a punching point anti-loosening method for countersunk screw connection. The connected part 1 is a steel piece, and the connected part 1 is provided with a 90° countersunk screw hole 5 . In specific implementation:

[0027] First, 2 to 4 V-shaped punching grooves 6 are machined on the edge of the countersunk screw hole 5 opening circumference. The width of the punching groove notch is 2 mm to 3 mm, and the V-shaped apex of the punching groove The angle between them is 60°, and the bisector of the top angle is perpendicular to the circumference of the countersunk screw hole 5 . The punching point grooves 6 are evenly distributed on the periphery of the countersunk screw hole 5 opening circumference. The angle bisector of the V shape of the punching point groove 6 is perpendicular to the center line of the countersunk screw hole 5 . In this embodiment, there are four punching grooves 6 with a width of 3 mm and a depth of 1.5 mm, which are evenly distr...

Embodiment 3

[0031] This embodiment is a punching point anti-loosening method for countersunk screw connection. The connected part 1 is a steel piece, and the connected part 1 is provided with a 90° countersunk screw hole 5 . In specific implementation:

[0032] First, 2 to 4 conical punching holes 3 are machined on the edge of the countersunk screw hole 5 opening circumference. The diameter of the punching hole opening is 2 mm to 3 mm, and the cone angle of the punching hole 60°, and the centerline of the punch hole is parallel to the centerline of the countersunk screw hole 5. The punching holes 3 are evenly distributed on the edge of the circumference of the countersunk screw holes 5 . In this embodiment, there are four punching holes 3 with a diameter of 3 mm and a depth of 1.5 mm, which are evenly distributed along the circumference of the countersunk screw holes 5 .

[0033] Align the countersunk screw hole 5 on the connected part 1 with the countersunk screw hole on the product ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com