Bellows stem assembly for high frequency quick opening valve

A technology for bellows valves and bellows sections, applied in the direction of threaded fasteners, valve devices, valve details, etc., can solve the problems of increasing the frequency of bellows replacement, cracking failure, fatigue failure of bellows valve stem components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

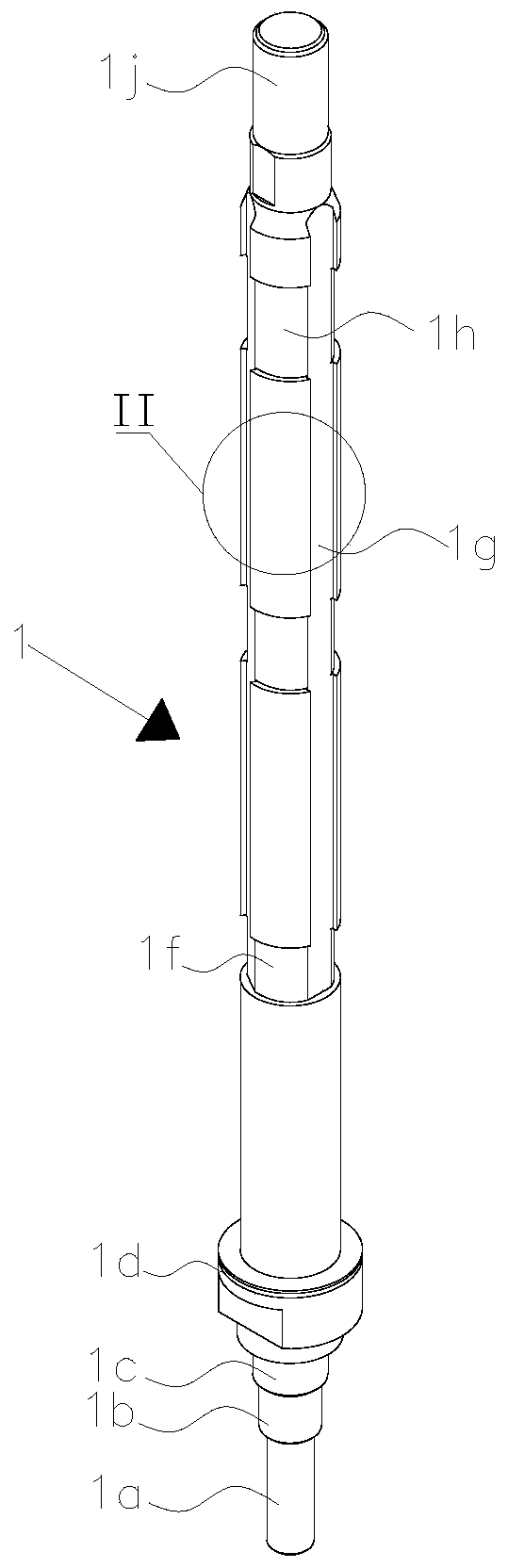

[0049] Such as image 3As shown, the valve rod 1 includes a shaft, an installation guide groove 1g provided in the axial direction of the shaft, and an annular limit groove 1f provided on the shaft body. The two ends of the shaft are respectively provided with a connecting section 1j of a driving device and a boss 1d. The boss 1d is sequentially connected with the disc installation section 1c, the lock nut installation section 1b and the guide section 1a. The disc installation section 1c is provided with left-handed threads; the lock nut installation section 1b is provided with right-hand threads, that is, the threads of the valve disc installation section 1c and the lock nut installation section 1b are in the opposite direction of rotation. An annular general limit groove 1h is opened on the shaft adjacent to the connecting section 1j of the driving device.

Embodiment 2

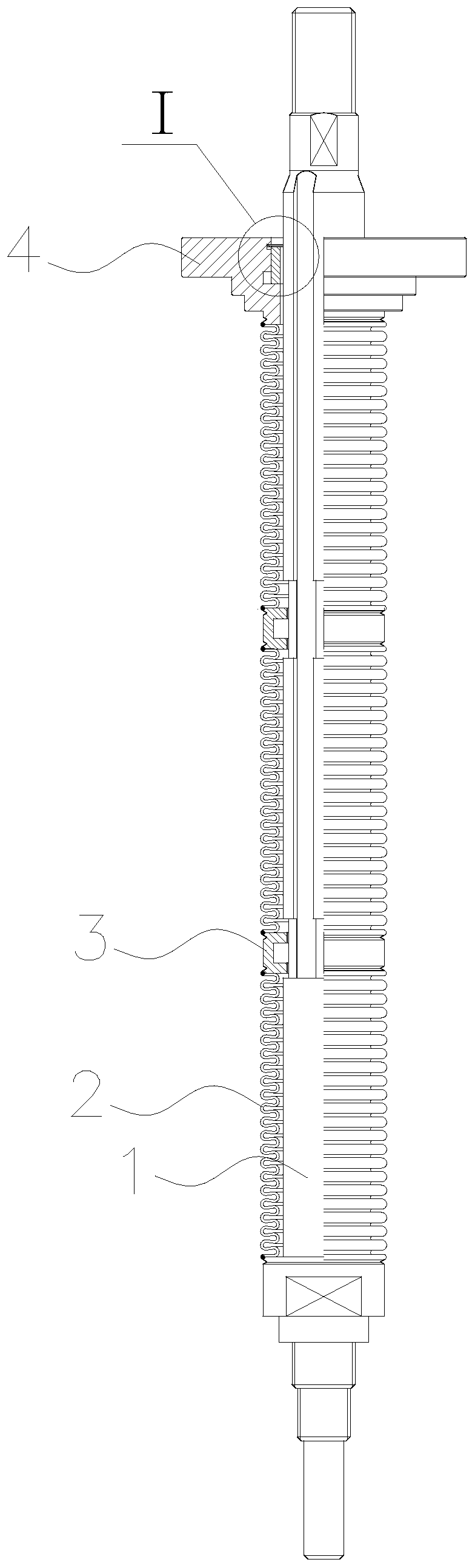

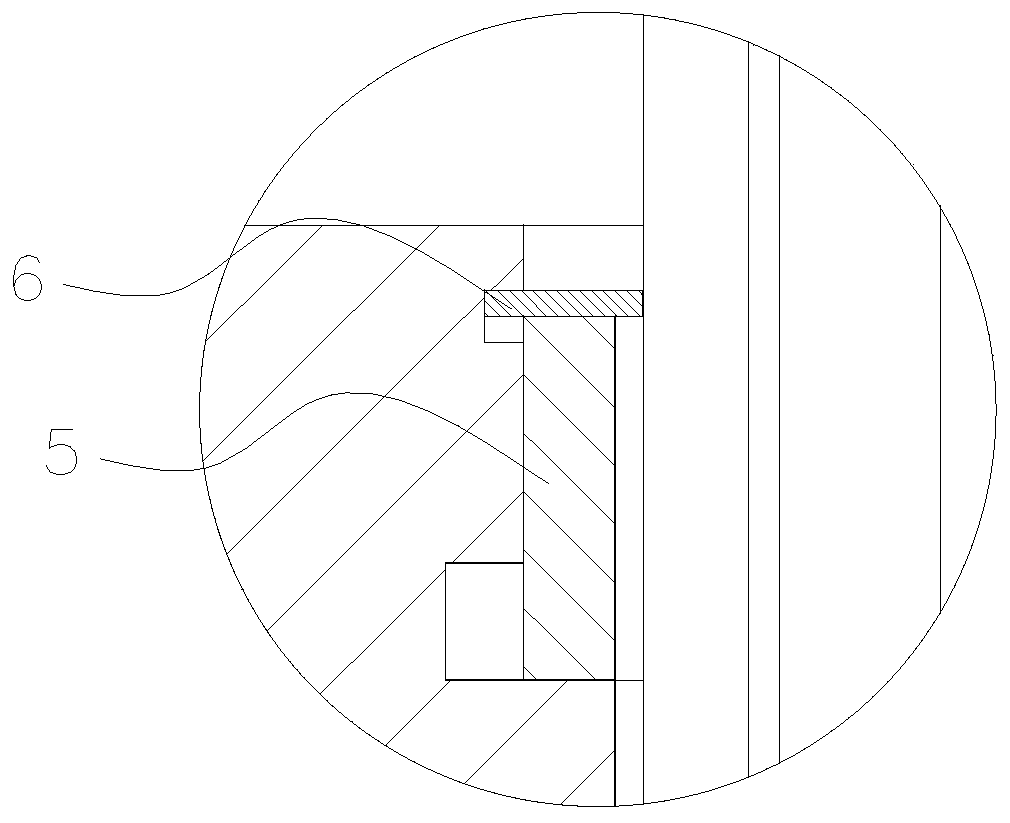

[0051] On the basis of Example 1, such as figure 1 As shown, a special bellows valve stem assembly for high-frequency quick-opening valves includes a valve stem 1, the valve stem 1 is covered with a bellows 2, and the bellows 2 includes several bellows sections arranged in sequence along the axial direction of the valve stem 1, several The bellows section is located between the boss 1d and the fixed flange 4, and the adjacent bellows sections are connected by the connecting ring 3 sleeved on the valve stem 1, and the connecting ring 3 is movably arranged in the annular limit groove 1f opened by the valve stem 1 Inside, the height of the annular limiting groove 1f is smaller than the maximum allowable deformation of the section of the bellows it limits, and the connecting ring 3 and the annular limiting groove 1f cooperate with each other to deform each section of the bellows.

[0052] From the boss 1d to the side of the fixed flange 4, the adjacent annular limiting grooves 1f ...

Embodiment 3

[0061] On the basis of Example 1 and Example 2, as Figure 5 and Figure 5B As shown, there are several raised connecting ring stoppers 3a on the mating surface between the connecting ring 3 and the valve stem 1, and the valve stem 1 is provided with an installation guide groove 1g along the axial direction, and the width of the connecting ring stopper 3a is slightly smaller than The width of the installation guide groove 1g, the connecting ring limit portion 3a and the annular limit groove 1f form a clearance fit, and the connection ring limit portion 3a is staggered by a certain angle around the axis of the valve stem 1 and the installation guide groove 1g.

[0062] In this embodiment, the installation guide groove 1g may also run through the entire valve stem 1 . Such as Figure 3A As shown, the installation guide groove 1g can be a keyway type guide groove 1k, such as Figure 3B As shown, the installation guide groove 1g can also be an arc bottom type guide groove 1m. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com