Car door lock mounting bolt

A technology for installing bolts and car door locks, which is applied in the direction of bolts, screws, nuts, etc., can solve problems such as frictional interference of the inner panel of the car door, monopoly of chemical glue technology, and loosening, so as to improve connection reliability, facilitate assembly, and prevent loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

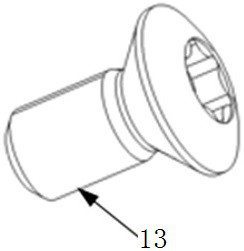

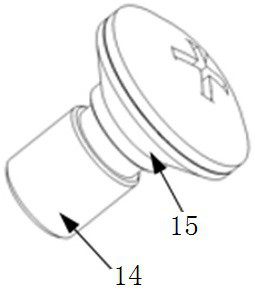

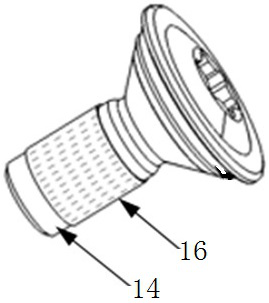

[0028] see Figure 4 to Figure 9 , the door lock installation bolt shown includes a bolt head 1 and a screw rod 2 , and a tapered transition wall 9 is provided between the bolt head 1 and the screw rod 2 . The bolt head 1 is injection-molded connected with a taper sleeve 3 correspondingly matched with the tapered hole on the car body. The surface interference fit plays a role of sealing, waterproofing and anti-scratch paint.

[0029] The screw 2 is provided with a threaded segment 5, and the threaded segment 5 is evenly provided with three helical anti-loosening grooves 6, so that the actual mating area between the anti-loosening grooves 6 and the internal thread of the vehicle body is evenly stressed, and the anti-loosening is more reliable . The anti-loosening groove 6 is specifically: the second thread 8 including the first thread 7 on the threaded segment 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com