Air supply adjustment valve for railway freight cars

A technology for railway wagons and regulating valves, which is applied in the direction of railway car body parts, control valves, balance valves, etc., and can solve the problem of reducing the reliability and safety of the air supply regulating valve, and the deformation of the copper diaphragm pressure ring and copper diaphragm , the difficulty of controlling the air filling speed, etc., to achieve the effect of improving the safety of use, reducing the number of connection points, and preventing loosening and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

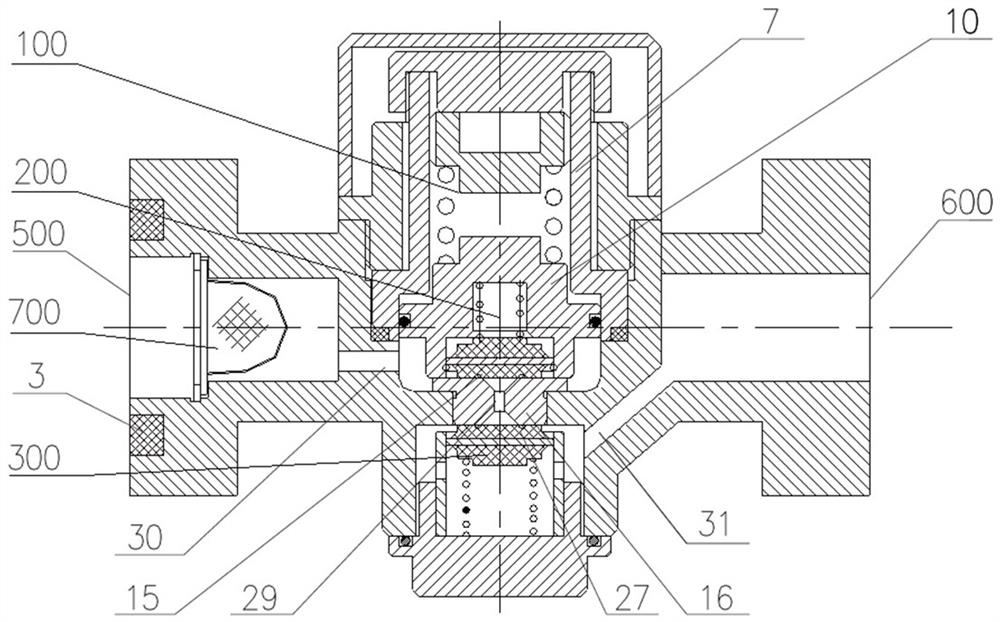

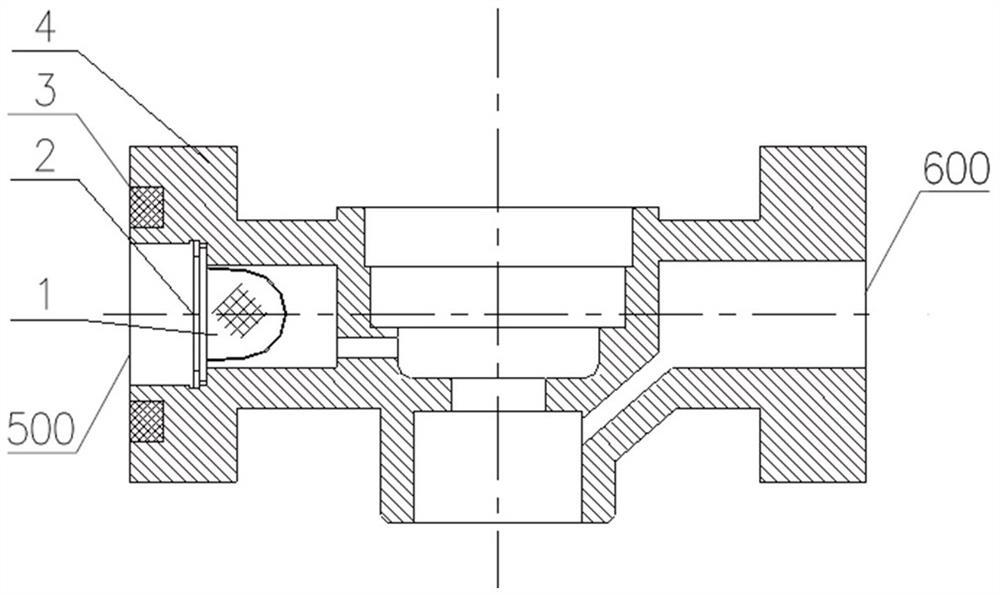

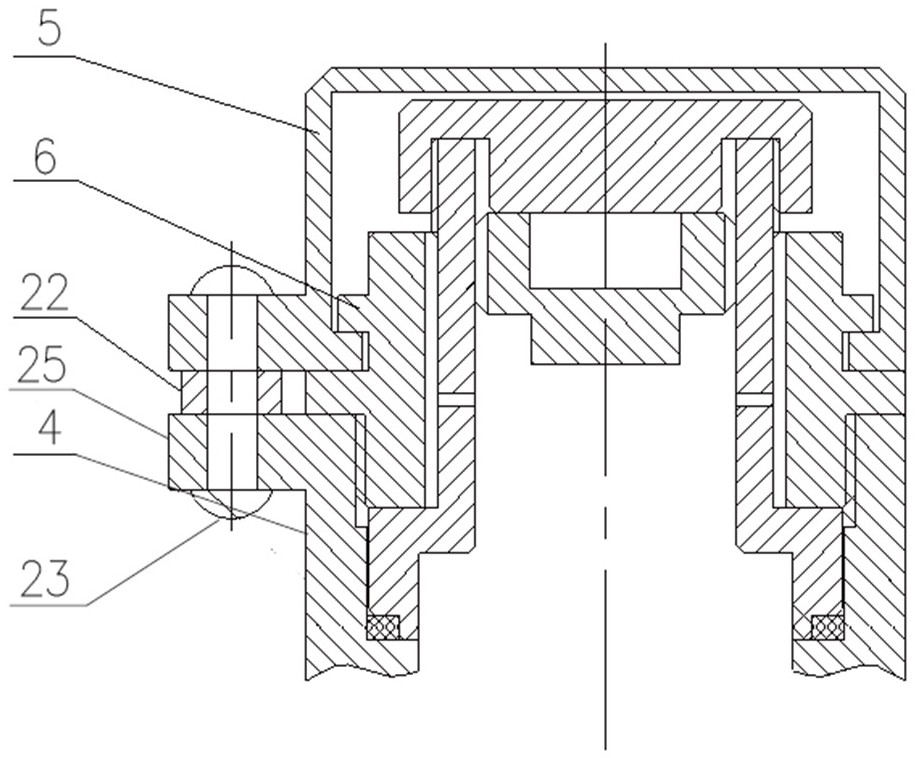

[0097] refer to Figure 1-Figure 10 As shown, this embodiment provides an air supply adjustment valve for a railway freight car, including:

[0098] The valve body 4, the two ends of the valve body 4 are respectively provided with an air inlet hole 500 and an air outlet hole 600, the middle part of the valve body 4 is sequentially provided with an upper cavity and a lower cavity from top to bottom, and a The valve seat 16, the middle part of the valve seat 16 is provided with a first ventilation hole 29 that first shrinks and then gradually expands from top to bottom;

[0099] The air charging valve part 200 is arranged in the upper chamber. The air charging valve part 200 includes a piston 10 and a piston cylinder 7 which are slidably arranged in the upper chamber. The lower part of the piston 10 is provided with a first sandwich valve 15. A first connection hole 30 communicating with the air inlet hole 500 is provided, and the first connection hole 30 is located below the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com