Special visual fast wrench in limited space

A technology of quick wrench and limited space, applied in the field of tools and wrenches, can solve the problems such as the inability to exert the advantages of the ratchet wrench, and achieve the effects of wide applicability, easy portability, and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

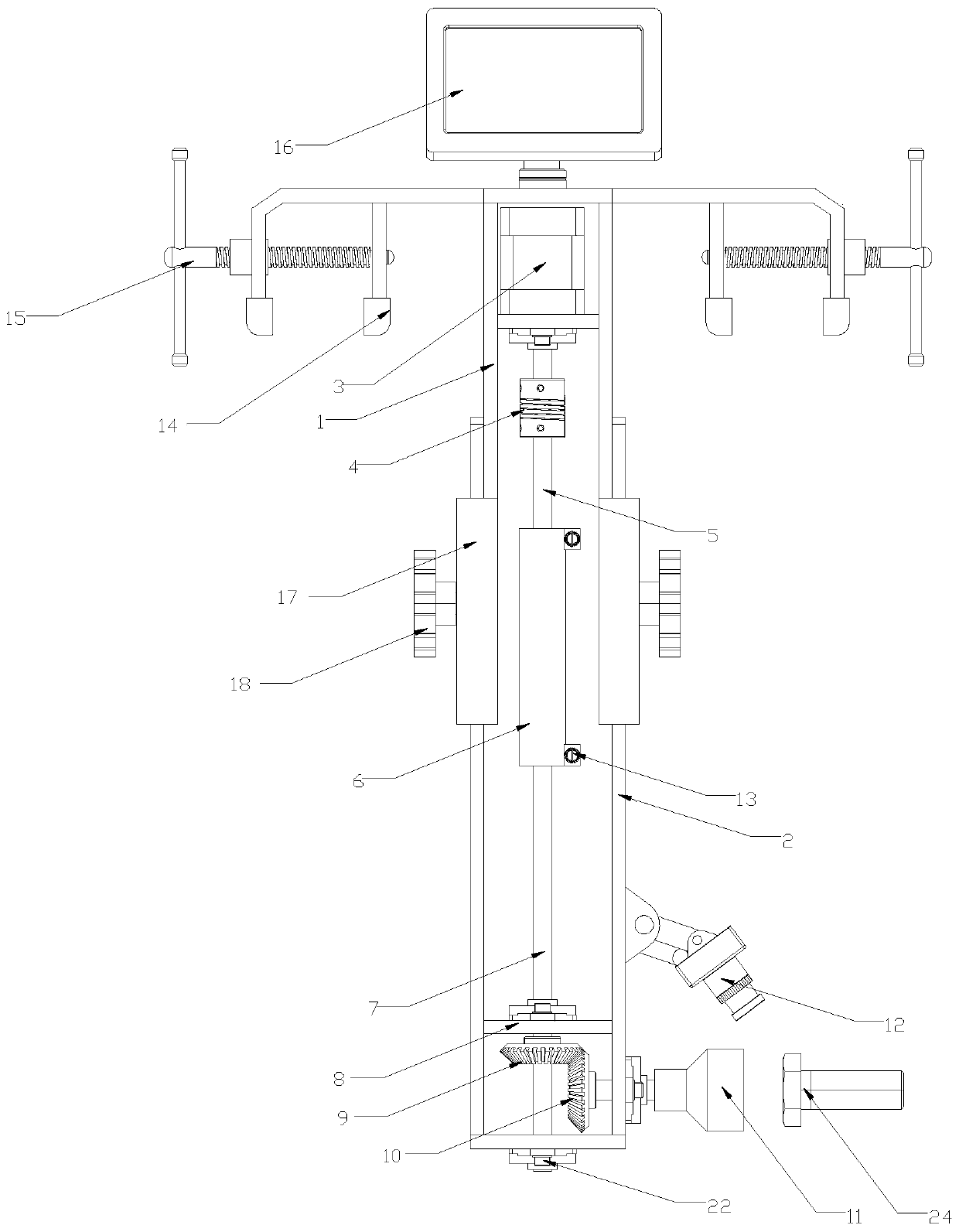

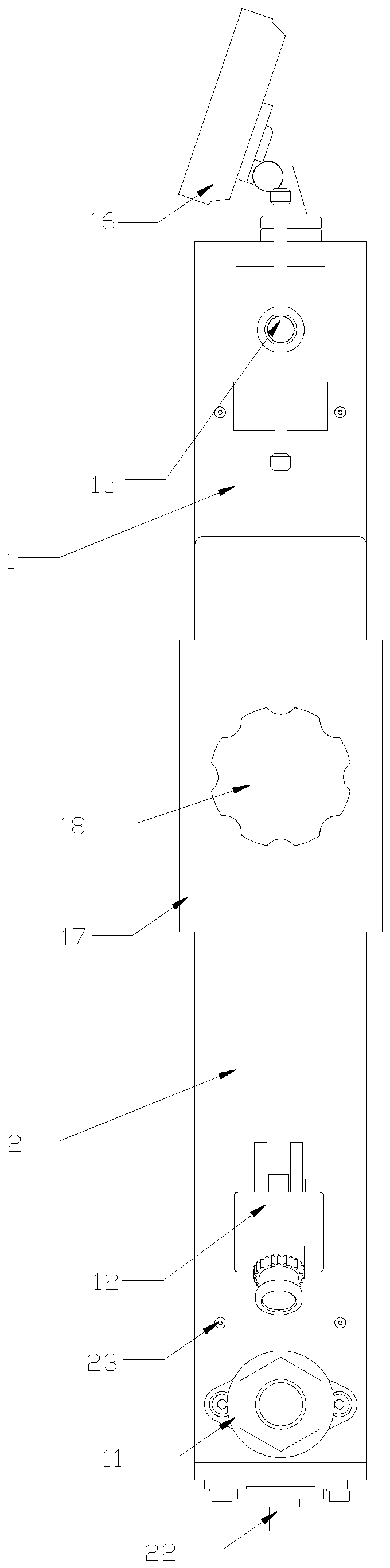

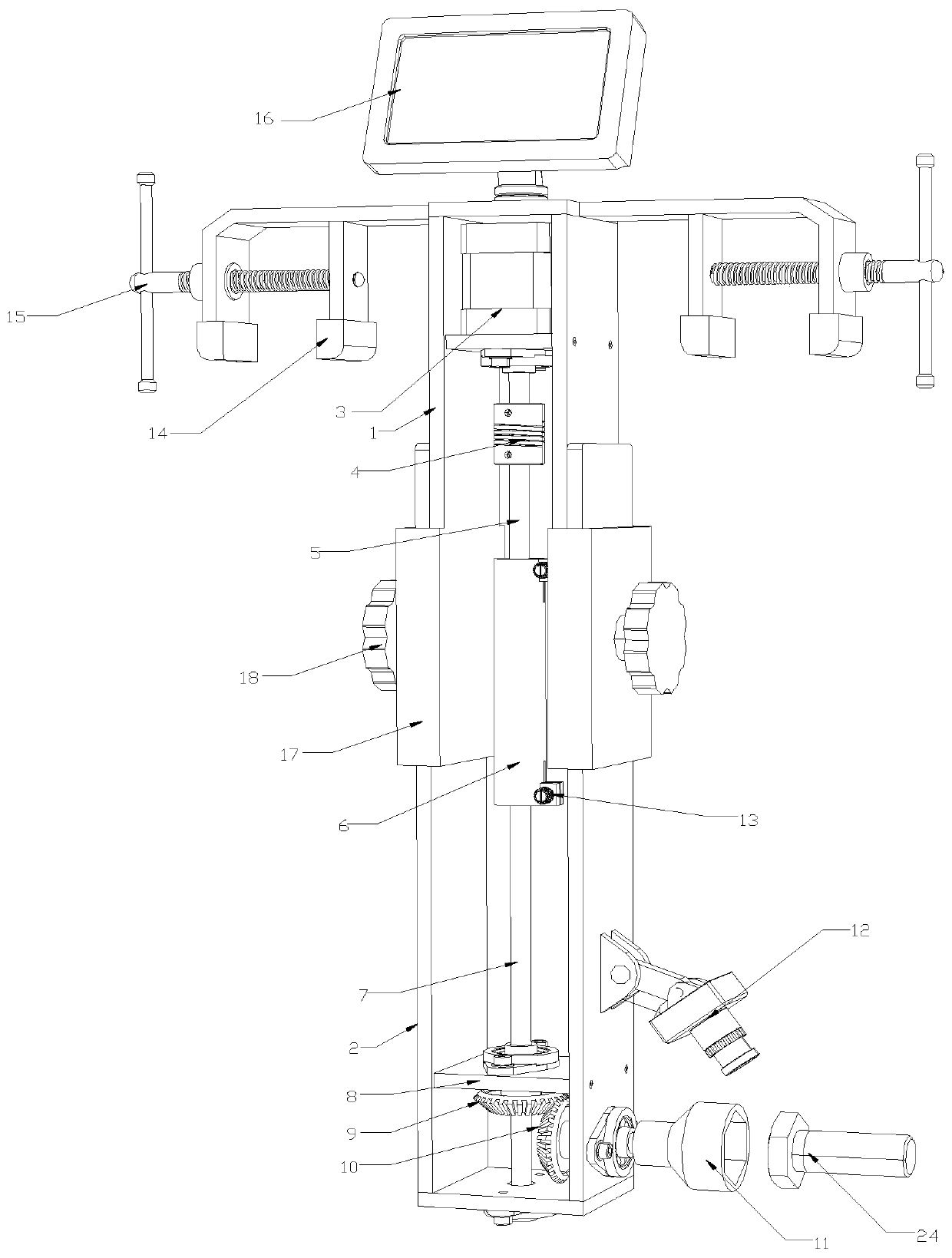

[0033] Embodiment 1: The special visual fast wrench for restricted space of the present invention

[0034] In the present invention, the fixing mechanism includes a frame body and a clamping mechanism, the driving mechanism is a stepping motor 3, and the transmission mechanism includes a coupling 4, an upper transmission shaft 5, a connecting sleeve 6, a lower transmission shaft 7, a reversing mechanism, and a motor 3 The lower part is provided with a coupling 4, and the lower part of the coupling 4 is provided with an upper transmission shaft 5 and a lower transmission shaft 7. The transmission shaft 1 and the lower transmission shaft 7 are connected by a connecting sleeve 6. The lower part of the fixing mechanism is provided with a bearing seat plate 8, and the bearing The seat plate 8 and the lower transmission shaft 7 are connected through a bearing seat. The lower transmission shaft 7 is located at the bottom of the bearing seat plate 8 and is provided with a reversing mec...

Embodiment 2

[0041] Embodiment 2: The special visual fast wrench for restricted space of the present invention

[0042] In the present invention, the frame body includes an upper frame body 1 and a lower frame body 2, and the upper frame body 1 and the lower frame body 2 are connected through a frame body connecting sleeve 17, and a frame body elastic nut 18 is provided on the frame body connecting sleeve 17.

[0043]In the present invention, a set of clamping mechanisms are respectively provided on both sides of the upper part of the frame body 1, and the clamping mechanism includes two telescopic splints 14 and a rocking bar 15. One end is provided with a rotating rod, and the end of the rocking rod 15 away from the rotating rod is provided with threads.

[0044] In the present invention, the driving mechanism is a stepper motor 3, the transmission mechanism includes a transmission rod and a commutator, the transmission rod includes a coupling 4, an upper transmission shaft 5, a connecti...

Embodiment 3

[0048] Embodiment three: the application of the device of the present invention

[0049] When applying the special visual quick wrench for the limited space of the present invention, first extend the wrench into the limited space, adjust the frame elastic nut 18 according to the position of the screw in the limited space, and adjust the upper frame body 1 and the lower frame body 2 to a suitable position. After the length, tighten the frame body elastic nut 18. Simultaneously, the bearing connection sleeve 6 between the upper transmission shaft 5 and the lower transmission shaft 7 also needs to perform the same operation by tightening the connection sleeve screw 13, so that the upper transmission shaft and the lower transmission shaft are adjusted to a suitable length.

[0050] Install the fastening head 11 compatible with the fastened screw 24, adjust the camera 12 to a suitable observation position by adjusting the support, adjust the universal bracket to adjust the display ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com