Aluminum material pressing mold

A technology for pressing molds and aluminum materials, which is applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of aluminum pressing offset, time-consuming and labor-intensive operation, not simple and convenient enough, etc., to ensure the quality of finished products, simple and convenient operation , good fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

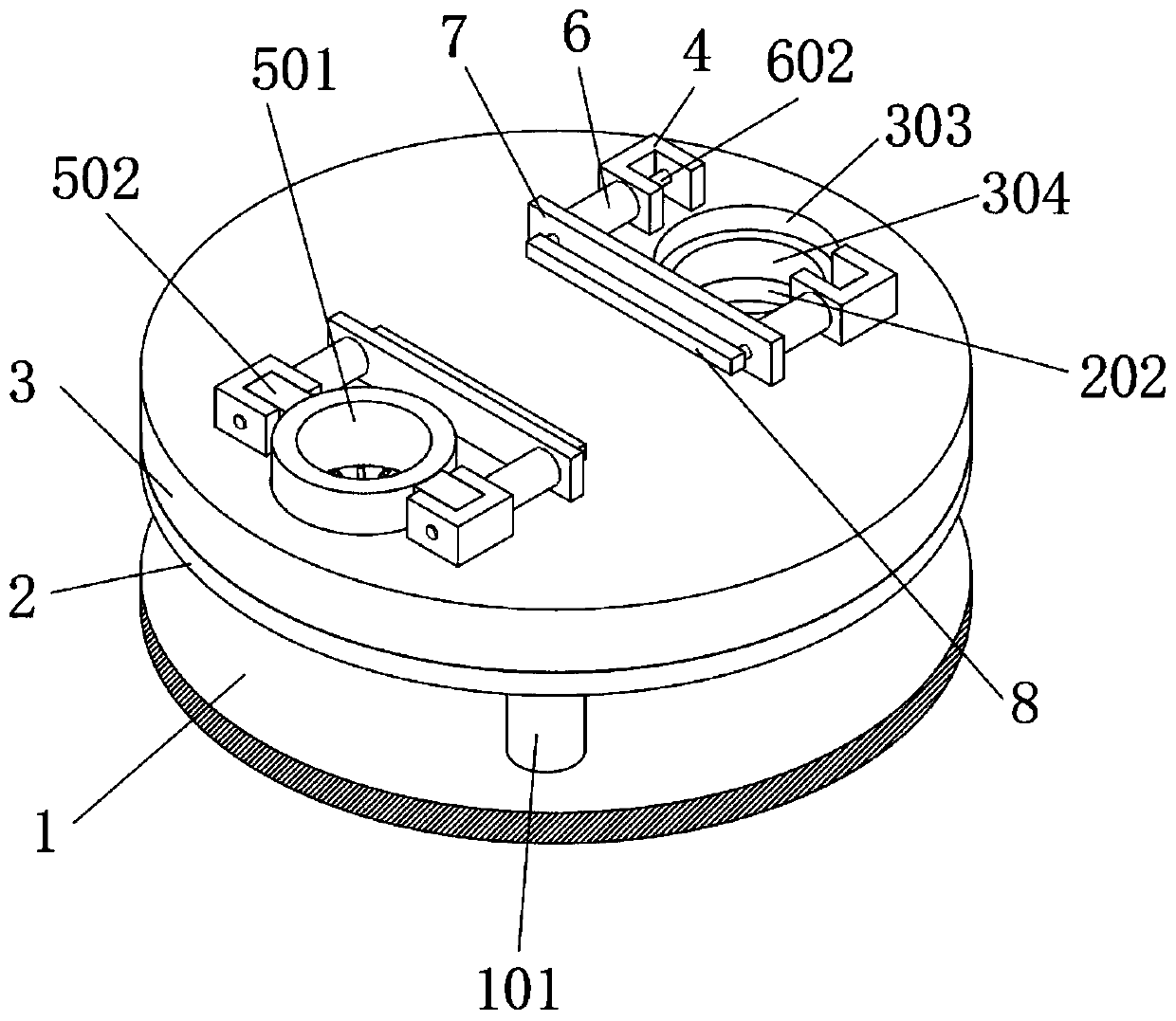

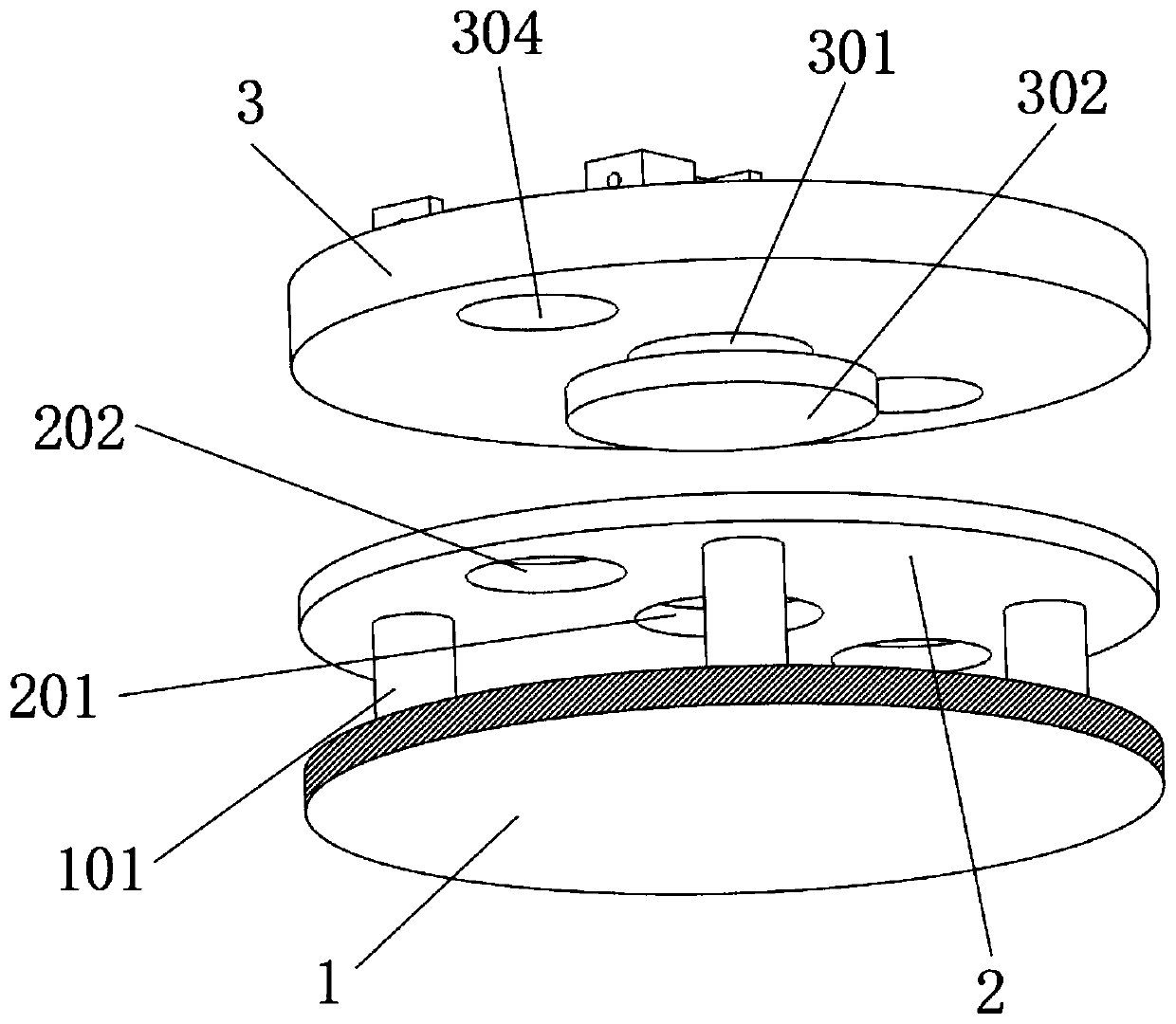

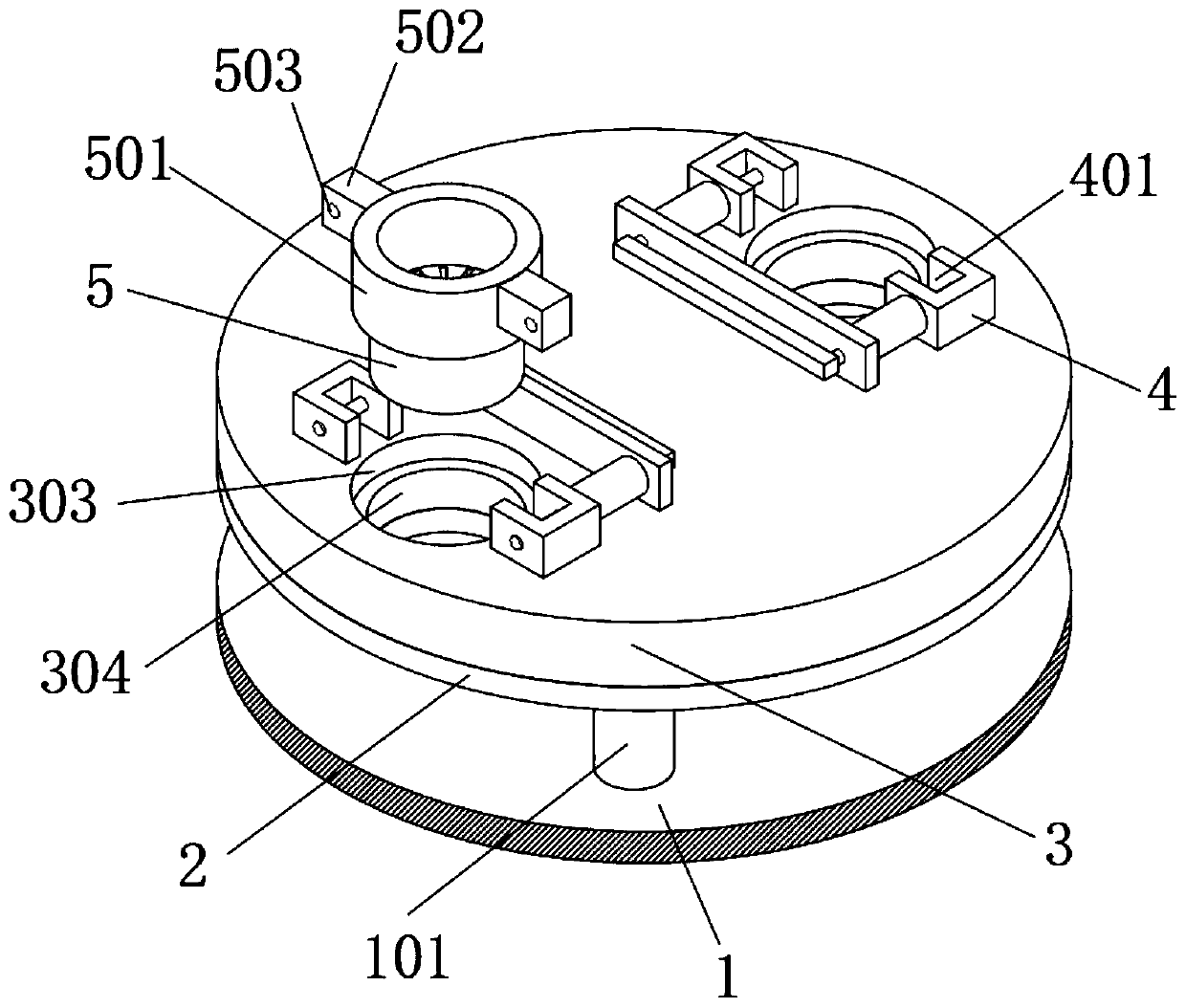

[0029] An embodiment of the present invention provides an aluminum pressing die, such as Figure 1-6 As shown, including the bottom plate 1 and the mold main body 5, the top of the bottom plate 1 is fixedly connected with four sets of support columns 101, the top of the support columns 101 is fixedly connected with the support plate 2, and the upper surface of the support plate 2 is rotatably connected with the rotating plate 3. The top of the plate 3 is provided with an outer cylinder groove 303, the bottom of the outer cylinder groove 303 is provided with a mold hole 304, the upper surface of the support plate 2 is provided with a locking hole 202 corresponding to the mold hole 304, and the mold body 5 is movably inserted into the In the mold hole 304 and the locking hole 202, the set mold body 5 is inserted into the mold hole 304 and the locking hole 202 at the same time, so that the rotating plate 3 can be engaged with the supporting plate 2, and the rotating plate 3 will n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com