Screw loosening monitoring device and system

A technology for monitoring devices and monitoring systems, applied in measuring devices, radio wave measuring systems, geophysical measurements, etc., can solve the problems of not adapting to curved surfaces and inaccurate judgments, and achieve high monitoring accuracy, improved work efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

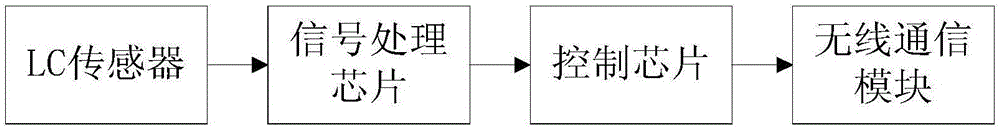

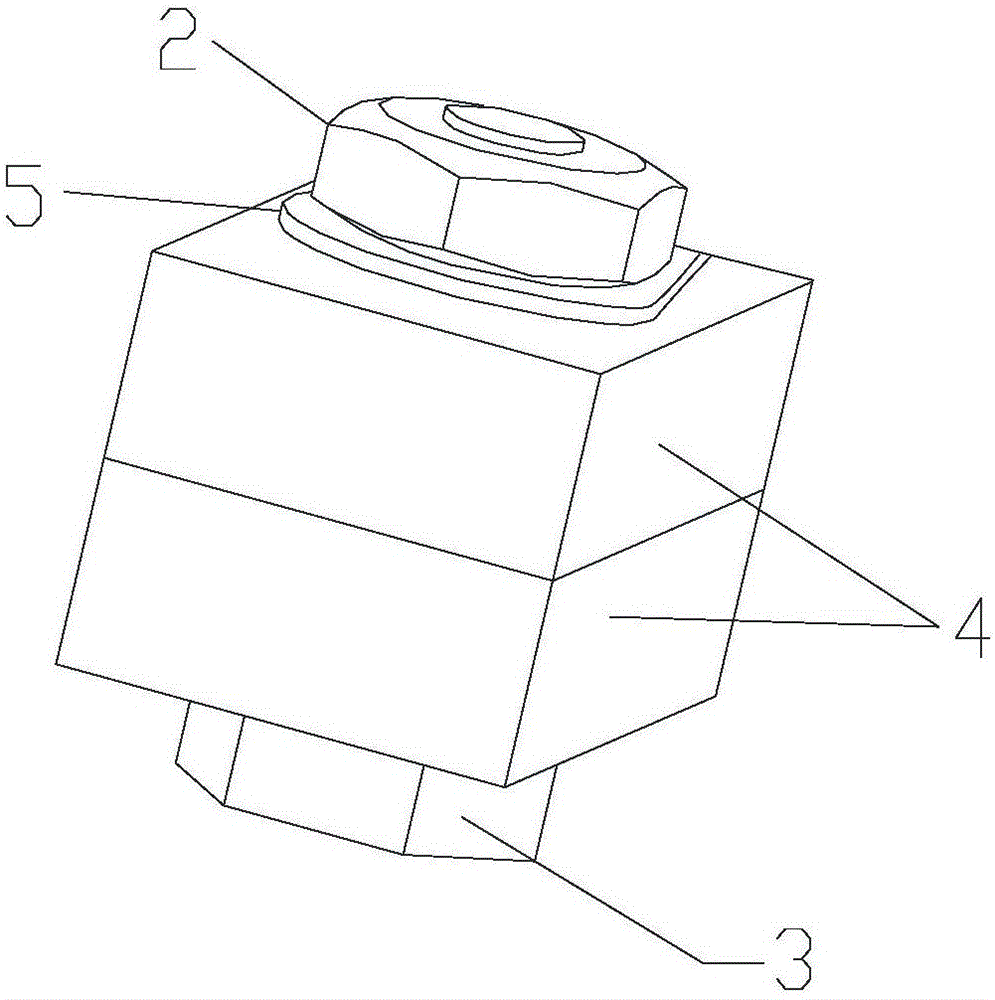

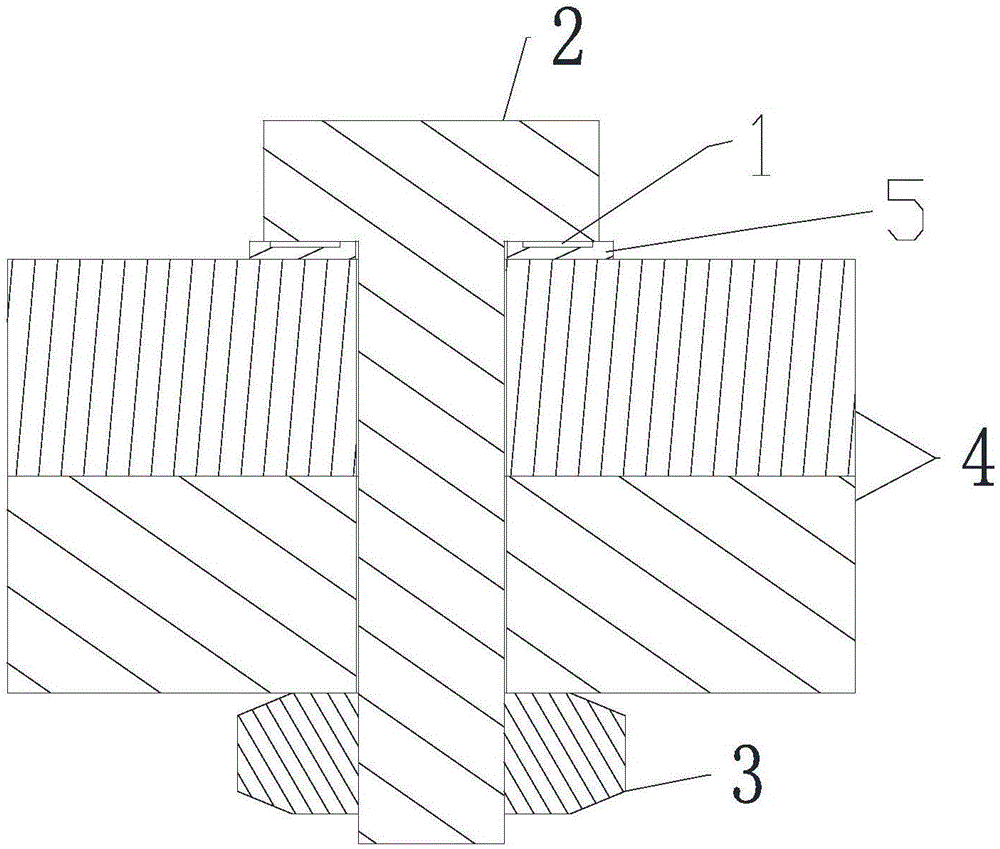

[0031] Such as figure 1 As shown, the present invention provides a screw loosening monitoring device, including an LC sensor 1, a signal processing chip, a control chip and a wireless communication module electrically connected in sequence, and the LC sensor 1 is a coil; in this embodiment, The LC sensor 1 is integrated on a non-metallic plate 5. The thickness of the LC sensor 1 can be tens of microns. According to the specific needs of the project, the coil can be made into various shapes, and can be manufactured flexibly, such as Figure 5 As shown, the coil can be directly embedded into the non-metallic plate 5, or as Image 6 As shown, each coil is separately arranged as a sensor on the non-metal plate 5, and the embedded sensors can be increased or decreased according to actual needs, and as Image 6 In the arrangement of coils, the inductance ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com