Wiring terminal with screw loosening alarming function

A technology of prompt function and terminal, applied in the direction of connection, electrical connection seat, clamping/spring connection, etc., can solve problems such as being difficult to detect and inconvenient for maintenance, and achieve the effect of reducing labor intensity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

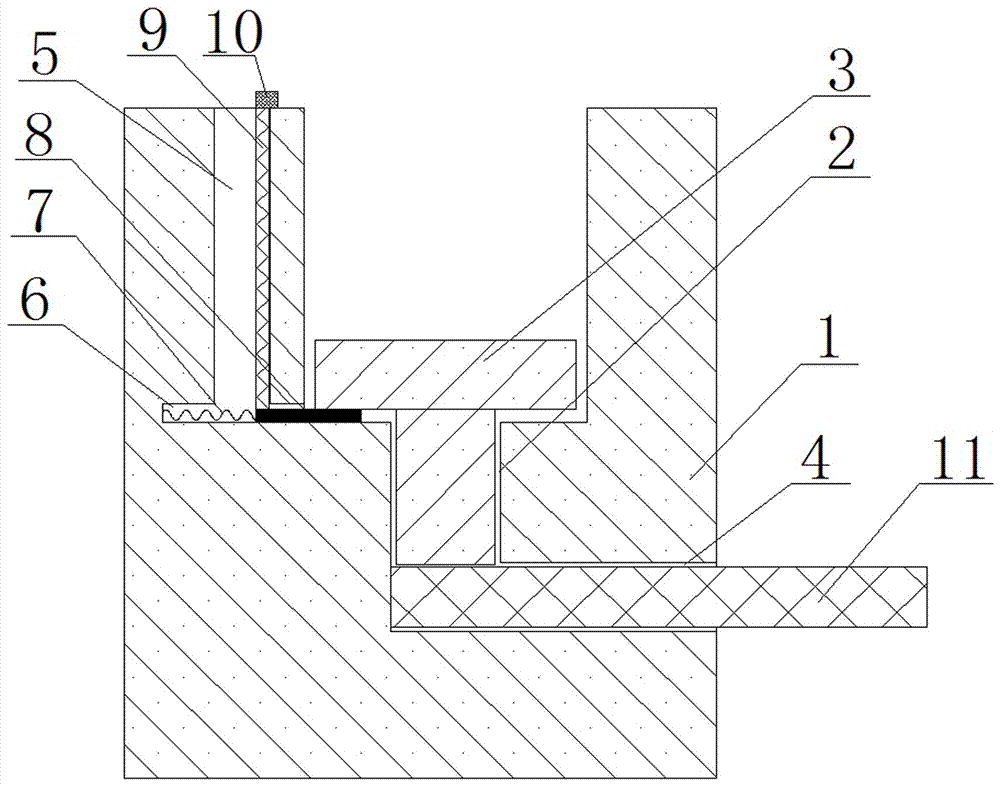

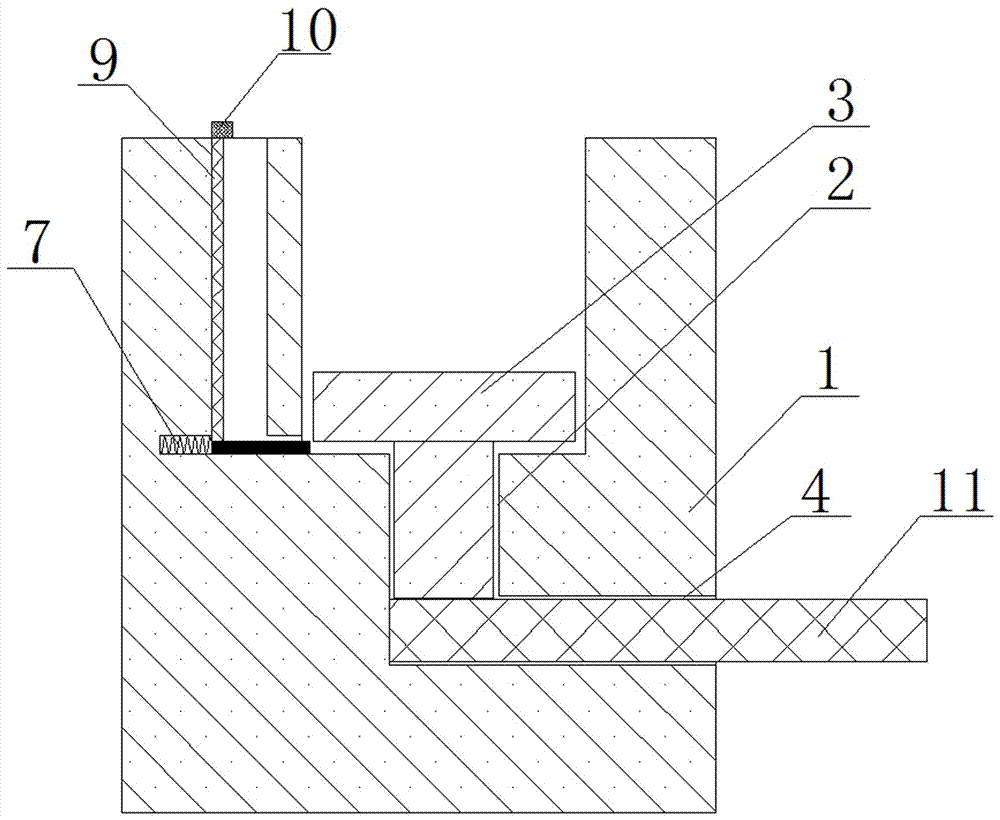

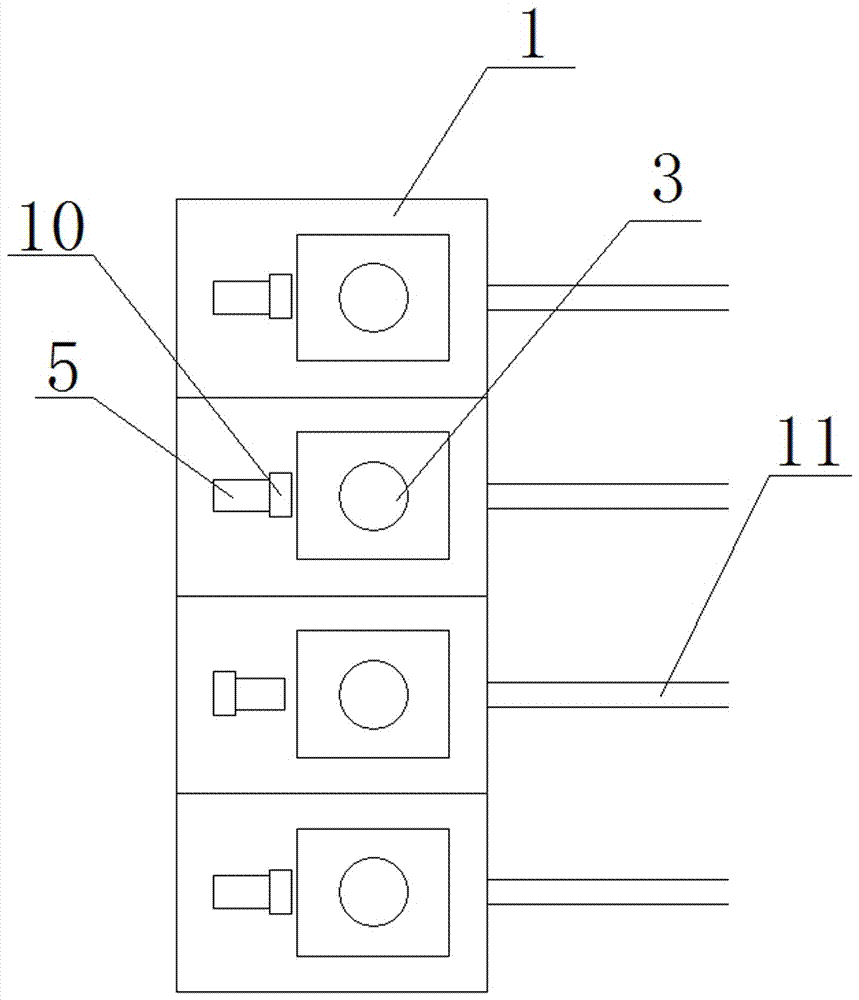

[0027] Such as figure 1 As shown, a connection terminal with a screw loosening prompt function includes a terminal base 1, wherein a threaded hole 2 is provided on the terminal base, and a matching pressing screw 3 is provided in the threaded hole 2, and the right side wall of the terminal base 1 is provided The wire inlet 4, the wire 11 passes through the wire inlet 4 and is compressed by the compression screw 3.

[0028] The left side wall of the terminal base 1 is provided with a longitudinal groove 5, wherein the bottom of the longitudinal groove 5 is provided with a transverse groove 6 communicating with it, and the right side of the transverse groove 6 is connected with the threaded hole 2, and a pressure plate 8 is arranged in the transverse groove 6, and the transverse groove 6 The left side wall of groove 6 is fixed with spring 7, and spring 7 is connected with pressing plate 8, and the left side of pressing plate 8 is fixed mobile plate 9, and mobile plate 9 is posit...

Embodiment 2

[0039] Embodiment 2 is basically the same structure as Embodiment 1, the difference is: as Figure 4 As shown, the inner wall of the terminal block 1 is provided with a pressing block 12, and the pressing block 12 is threadedly connected with the inner wall of the terminal block 1. This structure can further compress the pressing screw 3 through the pressing block 12 to reduce the loosening of the sending screw.

[0040] The insulating paint is sprayed on the pressing plate, wherein the insulating paint is prepared from the following raw materials in parts by weight: 68 parts of epoxy resin, 14 parts of silica sol, 9 parts of mica powder, 0.7 part of KH550, 17 parts of nano filler, 8 parts of rosin powder, 12 parts 3 parts of sodium alkyl sulfate, 4 parts of polyethylene glycol octyl phenyl ether, 35 parts of solvent, 0.65 part of curing agent and 0.4 part of defoamer.

[0041] The solvent is a mixture of ethanol and toluene at a volume ratio of 1:1.5; the nano-filler is a mix...

Embodiment 3

[0047] The connection terminal structure of embodiment 3 is the same as that of embodiment 1, the difference is:

[0048] The insulating coating is sprayed on the press plate, wherein the insulating coating is prepared from the following raw materials in parts by weight: 70 parts of epoxy resin, 13 parts of silica sol, 10 parts of mica powder, 0.8 part of KH550, 16 parts of nano filler, 9 parts of rosin powder, 12 parts 4 parts of sodium alkyl sulfate, 3 parts of polyethylene glycol octyl phenyl ether, 38 parts of solvent, 0.7 part of curing agent and 0.3 part of defoamer.

[0049] The solvent is a mixture of ethanol and toluene at a volume ratio of 1:1.5; the nano-filler is a mixture of nano-titanium dioxide and nano-silicon nitride at a weight ratio of 2:1.

[0050] The preparation method of insulating coating comprises the following steps:

[0051] (1) Dissolve mica powder, KH550, nano filler, sodium lauryl sulfate and polyethylene glycol octylphenyl ether in some solvents...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com