Well cementation flushing liquid system suitable for oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid and cementing technology, which is applied in the field of oil and gas well cementing, can solve the problems of poor interface cementation quality and low flushing efficiency, and achieve the effects of reducing interfacial tension, increasing flushing capacity, and increasing interface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Composition of a cementing flushing fluid system suitable for oil-based drilling fluids

[0029] A cementing flushing fluid system suitable for oil-based drilling fluid can be composed of the following substances, the mass parts of each substance are: 100 parts of clear water, 1 part of anionic surfactant sodium dodecylbenzene sulfonate, non-ionic surfactant Active agent fatty alcohol polyoxyethylene ether AEO-90.7 parts, co-surfactant n-butanol 0.7 parts, oil phase n-heptane 7 parts, saline phase potassium chloride aqueous solution 9 parts, polymer carboxymethyl hydroxyethyl cellulose 3 parts, 32 parts of weighting agent quartz sand, 2 parts of potassium chloride, the density of the washing liquid is 1.2g / cm 3 .

Embodiment 2

[0030] Embodiment 2: A kind of composition that is suitable for the cementing flushing fluid system of oil-based drilling fluid

[0031] A cementing flushing fluid system suitable for oil-based drilling fluid can be composed of the following substances, the mass parts of each substance are: 100 parts of clear water, 0.8 parts of anionic surfactant sodium dodecylsulfonate, nonionic surfactant Agent polyol ester Tween800.6 parts, co-surfactant propylene glycol butyl ether 0.8 parts, oil phase cyclohexane 6 parts, brine phase sodium chloride aqueous solution 8 parts, polymer polyvinyl alcohol 5 parts, weighting agent barite 94 1 part, 2 parts of sodium chloride, the density of the washing liquid is 1.7g / cm 3 .

Embodiment 3

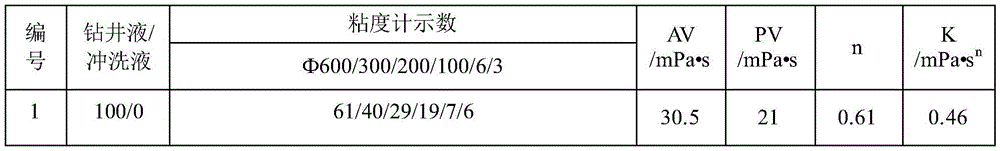

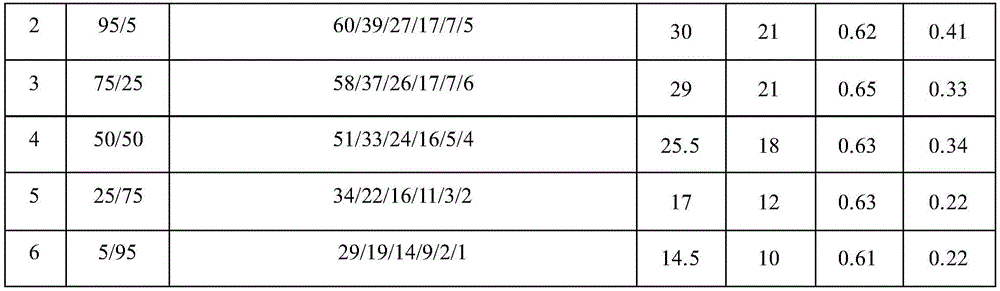

[0032] Example 3: Compatible rheological evaluation of flushing fluid system

[0033] Taking the flushing fluid system of Example 1 as the test object, first prepare the flushing fluid, and then evaluate the compatible rheology according to the Petroleum and Natural Gas Industry Standard SY / T5374-2000 of the People's Republic of China "Methods for Using the Pre-fluid for Cementing in Oil and Gas Wells", and the drilling fluid / The flushing fluid is mixed according to the ratio of 95 / 5, 75 / 25, 50 / 50, 25 / 75, and 5 / 95, and the rheological properties are measured with a six-speed viscometer, and compared with the drilling fluid without flushing fluid, the test temperature 70°C. The oil-based drilling fluid formula used is: white oil + 1.5% VG-69 organic soil + 0.5% LCR-01D main emulsifier + 3% fluid loss reducer + 25% water + 5% calcium chloride + 0.5% auxiliary Emulsifier, the drilling fluid density is 1.30g / cm 3 . The test results are shown in Table 1.

[0034] Table 1 Compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com