Method for recovering rhenium from arsenic filter cake

A filter cake, potassium perrhenate technology, applied in the direction of improving process efficiency, can solve problems such as high cost, low rhenium recovery rate, difficult to handle, etc., and achieve the effects of short process flow, short processing process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

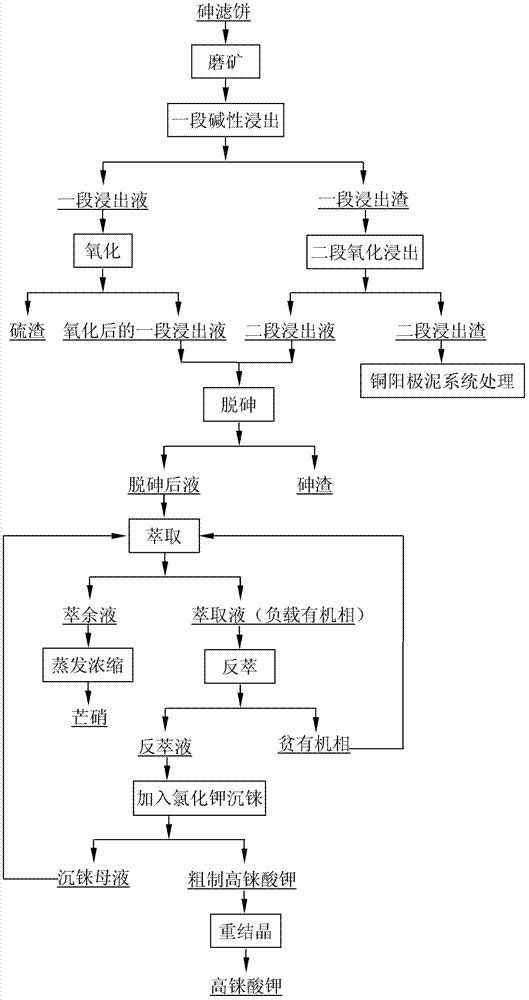

Image

Examples

Embodiment 1

[0065] Using arsenic filter cake from a domestic copper smelter as raw material, the main components (mass content) are Re: 1580-1620g / t, As: 20.0%-21.5%, S: 53%-55%, Se: 1.8%- 1.9%, Bi: 2.9%-3.2%, Cu: 1%-1.5%, Pb: 2.5%-2.8%, and the rest are impurities.

[0066] In one leaching process, sodium hydroxide with 50% raw material amount is added, the liquid-solid ratio is controlled at 3:1, the leaching temperature is controlled at 90° C., and the leaching time is 4 hours. The leaching rate of rhenium is 94%, the leaching rate of arsenic is 98%, the leaching rate of selenium is 3%, and the lead, bismuth and copper are enriched in the leaching slag. scum.

[0067] Add 25g / L sodium hypochlorite to the first-stage leaching residue for second-stage leaching, control the liquid-solid ratio to 3:1, control the leaching temperature to 60°C, leaching time to 2h, and control the solution oxidation potential to ≥200mv. In the second-stage leaching process, the leaching rate of rhenium is ...

Embodiment 2

[0073] Using arsenic filter cake from a domestic copper smelter as raw material, the main components (mass content) are Re: 1580-1620g / t, As: 20.0%-21.5%, S: 53%-55%, Se: 1.8%-1.9 %, Bi: 2.9%-3.2%, Cu: 1%-1.5%, Pb: 2.5%-2.8%, and the rest are impurities.

[0074] In one leaching process, 60% of the raw material amount of sodium carbonate is added, the liquid-solid ratio is controlled at 4:1, the leaching temperature is controlled at 95° C., and the leaching time is 5 hours. The leaching rate of rhenium is 92%, the leaching rate of arsenic is 96%, the leaching rate of selenium is 1%, and the lead, bismuth and copper are enriched in the leaching slag. scum.

[0075] About 27% hydrogen peroxide is added to the first-stage leaching residue to carry out the second-stage leaching, the liquid-solid ratio is controlled to be 4:1, the leaching temperature is controlled at 80°C, the leaching time is 4h, and the oxidation potential of the solution is controlled to be ≥200mv. In the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com