Method for recovering rhenium from high-temperature alloy pickle liquor

A technology of superalloy and acid leaching solution, applied in the field of rare metal resource recovery and utilization, can solve the problems of long recovery process, complicated procedures, large rhenium loss, etc., and achieve high direct rhenium yield, simple operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

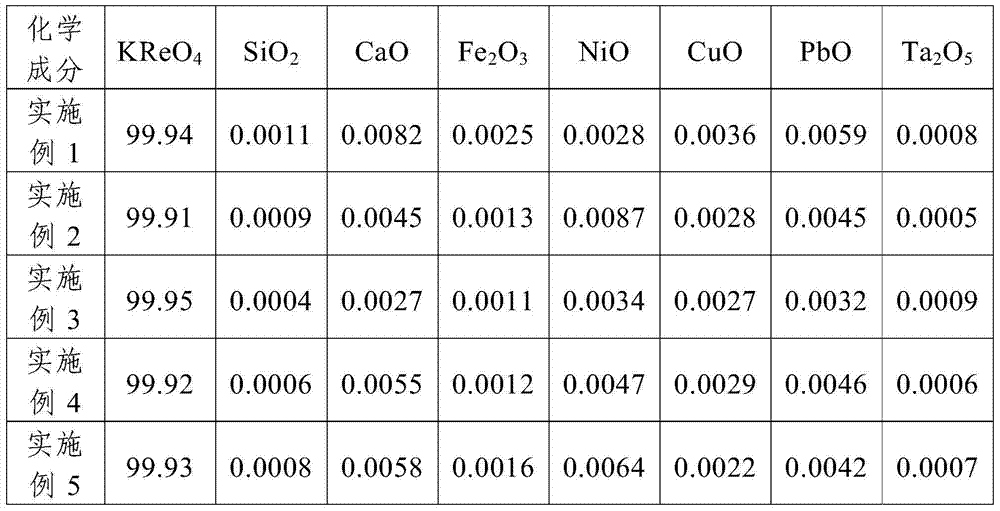

Examples

Embodiment 1

[0021] The method for reclaiming rhenium from the superalloy acid leaching solution in this embodiment comprises the following steps:

[0022] Step 1, using saturated sodium carbonate solution to adjust the pH value of the superalloy pickling solution to 1.5, and then using ion exchange resin to carry out ion exchange treatment on the high temperature alloy pickling solution with a pH value of 1.5, so that the high temperature alloy pickling solution Rhenium and molybdenum are adsorbed on the ion exchange resin; the ion exchange resin is a macroporous D296 strong basic anion exchange resin; the pH of the superalloy acid immersion solution is -1.37, and contains nickel, cobalt, molybdenum and rhenium elements , the contents of nickel, cobalt, molybdenum and rhenium in the superalloy acid immersion solution measured before and after ion exchange treatment are shown in Table 1;

[0023] Step 2, first prepare the mixed solution of ammoniacal liquor and ammonium chloride, the prepa...

Embodiment 2

[0029] The method for reclaiming rhenium from the superalloy acid leaching solution in this embodiment comprises the following steps:

[0030] Step 1. Adjust the pH value of the superalloy acid leaching solution to 1.8 with a saturated sodium hydroxide solution, and then use an ion exchange resin to perform ion exchange treatment on the high temperature alloy acid leaching solution with a pH value of 1.8, so that the superalloy acid leaching solution The rhenium and molybdenum are adsorbed on the ion exchange resin; the ion exchange resin is a gel-type 201×7 strong basic anion exchange resin; the pH of the superalloy acid dipping solution is -0.56, and contains nickel, cobalt, and molybdenum , rhenium element, the contents of nickel, cobalt, molybdenum and rhenium in the superalloy acid immersion solution measured before and after ion exchange treatment are shown in Table 2;

[0031] Step 2, first prepare the mixed solution of ammoniacal liquor and ammonium chloride, the prepa...

Embodiment 3

[0037] The method for reclaiming rhenium from the superalloy acid leaching solution in this embodiment comprises the following steps:

[0038]Step 1. Adjust the pH value of the superalloy pickling solution to 1.2 with a saturated solution of sodium carbonate, and then use an ion exchange resin to carry out ion exchange treatment on the high temperature alloy pickling solution with a pH value of 1.2, so that the high temperature alloy pickling solution Rhenium and molybdenum are adsorbed on the ion-exchange resin; the ion-exchange resin is a gel-type 201×4 strongly basic anion-exchange resin; the pH=-2.18 of the high-temperature alloy acid immersion solution contains nickel, cobalt, molybdenum, Rhenium element, the contents of nickel, cobalt, molybdenum and rhenium in the superalloy acid immersion solution measured before and after ion exchange treatment are shown in Table 3;

[0039] Step 2, first prepare the mixed solution of ammoniacal liquor and ammonium chloride, the prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com