Preparation method of silicon dioxide aerogel and prepared silicon dioxide aerogel

A silica and aerogel technology, applied in silica, silica, chemical instruments and methods, etc., can solve the problems of cumbersome operations, multiple times, and long preparation cycles, so as to reduce preparation time and avoid solid waste. , to avoid the effect of various pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

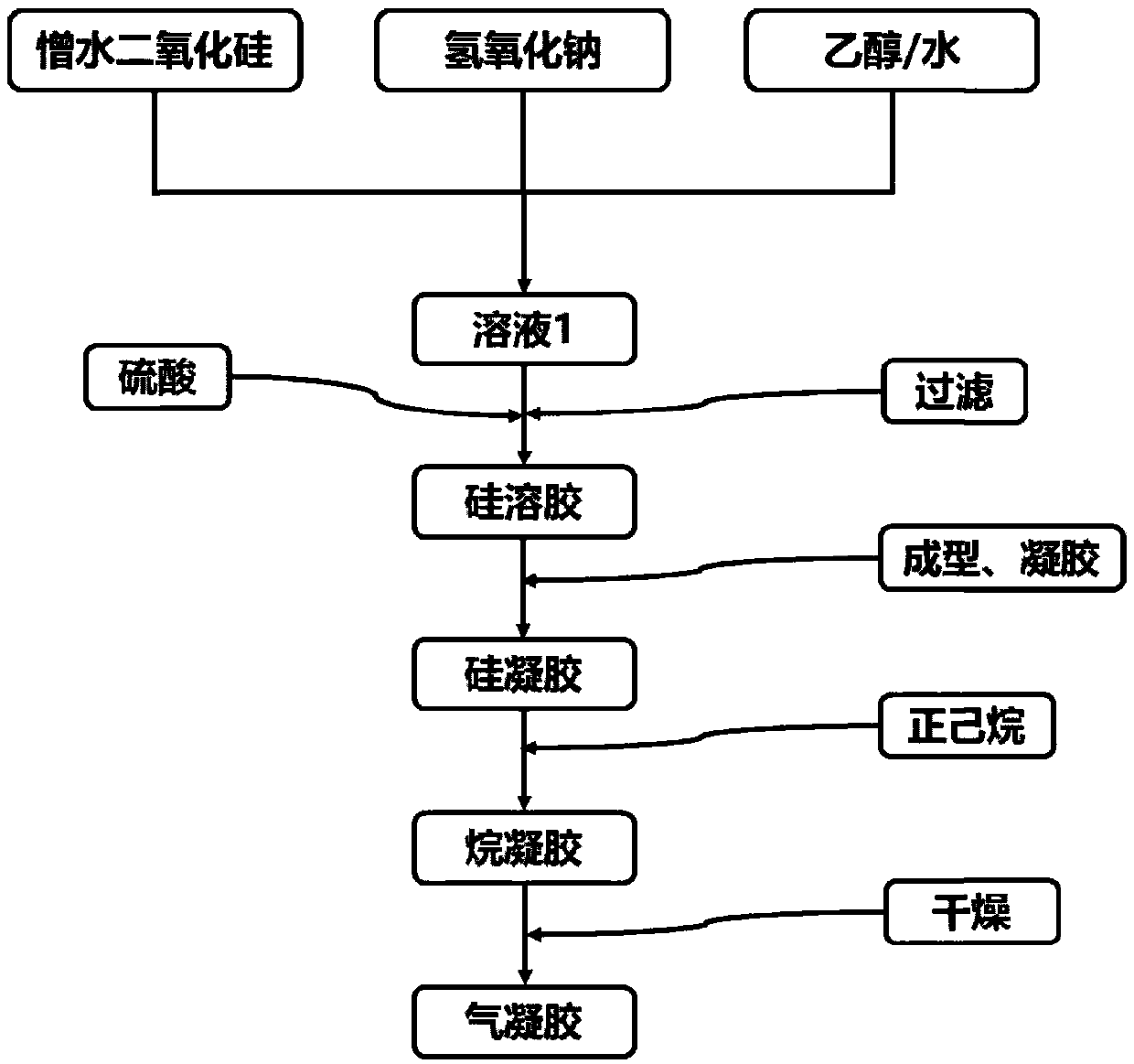

[0037] A preparation method of silica airgel, comprising the following steps:

[0038] (1) Mix 40g sodium hydroxide, 500g water, and 500g ethanol into a uniform solution, add 50g of hydrophobic fumed silica, and dissolve to become a clarified modified sodium silicate liquid;

[0039] (2) adding 85g mass fraction of 50% sulfuric acid solution into the modified sodium silicate liquid and stirring, so that the pH value of the solution is between 4-6, because this reaction is an exothermic reaction in order to control the reaction speed, the acid solution The joining speed should not be too fast;

[0040] (3) After stirring and cooling to room temperature, the solution was filtered to remove the precipitated sodium sulfate crystals to obtain a clear solution, which was left to stand at 60° C. for 1 hour to obtain a modified silica gel;

[0041] (4) Add 1000g of n-heptane solution to the gel and heat it to 90°C. After 3 hours, the solution is layered. The upper layer is silica gel...

Embodiment 2

[0046] A preparation method of silica airgel, comprising the following steps:

[0047] (1) Mix 20g sodium hydroxide, 1000g water, and 500g ethanol into a uniform solution, add 50g of hydrophobic fumed silica, and dissolve to become a clarified modified sodium silicate liquid;

[0048] (2) adding 150g mass fraction of 40% nitric acid solution into the modified sodium silicate liquid and stirring, because this reaction is an exothermic reaction in order to control the reaction speed, the acid solution addition speed should not be too fast;

[0049] (3) After stirring and cooling to room temperature, the solution was filtered to remove the precipitated sodium nitrate crystals to obtain a clear solution, which was left to stand at 60°C for 40 minutes to obtain a modified silica gel;

[0050] (4) Add 600 g of n-hexane solution to the gel and heat it to 70°C. After 3 hours, the solution is layered. The upper layer is silica gel and n-pentane solution, and the lower layer is ethanol ...

Embodiment 3

[0053] A preparation method of silica airgel, comprising the following steps:

[0054] (1) Mix 100g of sodium hydroxide, 50g of water, and 500g of ethanol into a uniform solution, add 50g of hydrophobic fumed silica, and dissolve to become a clarified modified sodium silicate liquid;

[0055] (2) adding 100g mass fraction of 20% hydrochloric acid solution into the modified sodium silicate liquid and stirring, because this reaction is an exothermic reaction in order to control the reaction speed, the acid solution addition speed should not be too fast;

[0056] (3) After stirring and cooling to room temperature, the solution was filtered to remove the precipitated sodium chloride crystals to obtain a clear solution, which was left to stand at 60° C. for 1 hour to obtain a modified silica gel;

[0057] (4) Add 600g of hexamethyldisiloxane solution to the gel and heat it to 70°C. After 3 hours, the solution is layered. The upper layer is silica gel and hexamethyldisiloxane soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

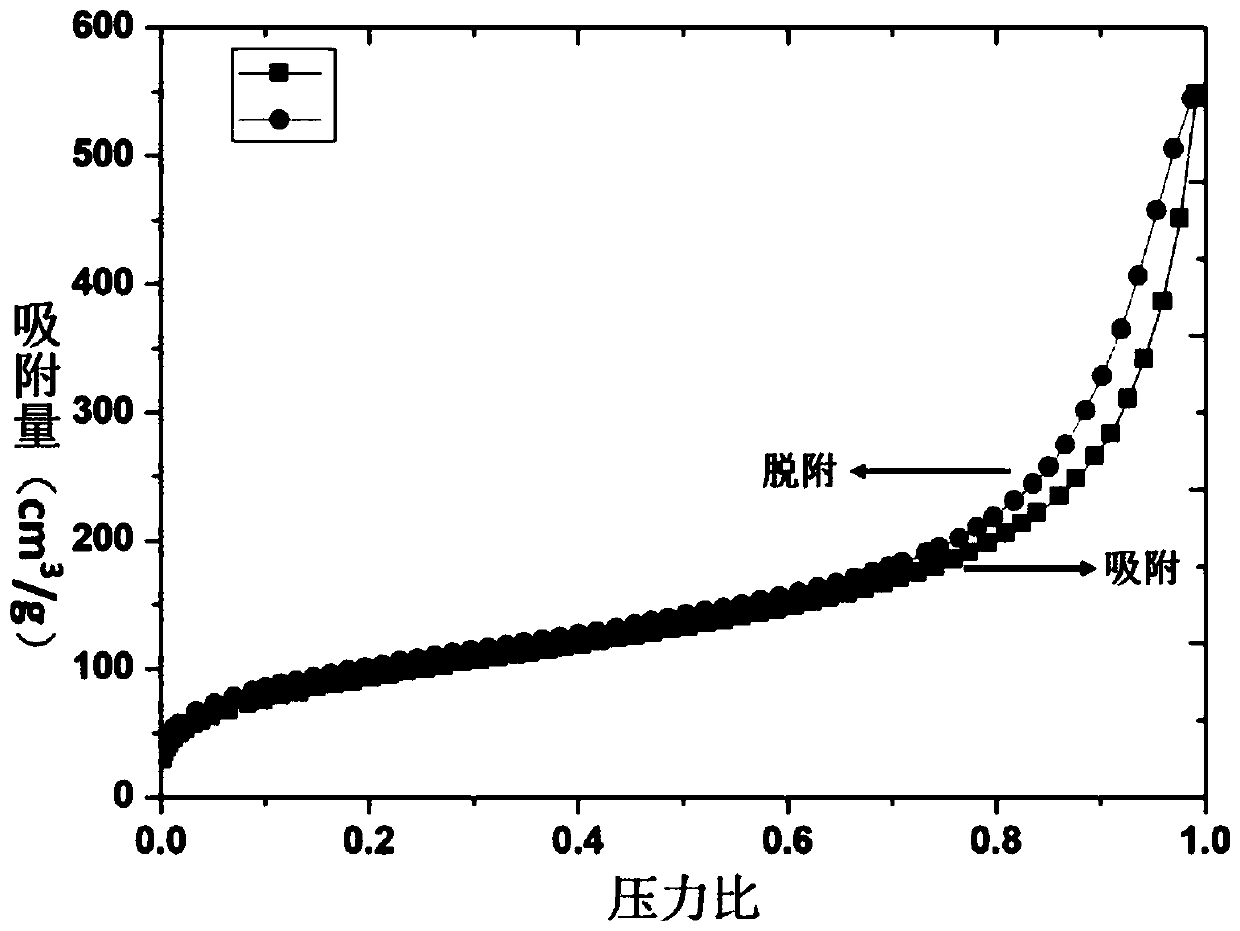

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com