Method for preparing 3,3-dimethyl-1-butanol

A technology of dimethyl and butanol, which is applied in the preparation of hydroxyl compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of difficult post-processing, reduced reaction yield, high conversion rate, etc. The effect of high product purity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

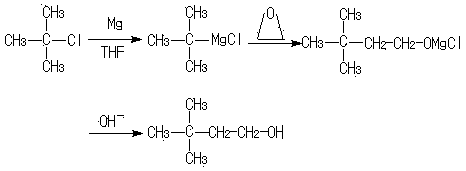

Image

Examples

Embodiment 1

[0024] Prepare 3, the concrete preparation steps of 3-dimethyl-1-butanol are as follows:

[0025] ①In a 1000ml four-neck flask equipped with a thermometer, reflux condensing device, drying device, dropping device, and stirring device, add 26.4g (1.1mol) of magnesium powder, and at the same time add 100ml of ether solvent tetrahydrofuran to immerse the magnesium powder, and heat to 45 After ℃, add 3g initiator bromoethane to initiate the reaction and produce violent reflux. After the reflux is stable, add dropwise the mixed liquid of 92.5g (1mol) chlorobutane and 400ml ether solvent tetrahydrofuran, and keep the reflux during the dropping process. Adding time is 45 minutes, after the dropwise addition is completed, keep refluxing for 3.5 hours, and the resulting reaction solution is Grignard reagent tert-butylmagnesium chloride;

[0026] ② Cool the reaction liquid Grignard reagent tert-butylmagnesium chloride prepared in step ① to 20°C, feed ethylene oxide gas and control the v...

Embodiment 2

[0031] Prepare 3, the concrete preparation steps of 3-dimethyl-1-butanol are as follows:

[0032] ① Add 27.6g (1.15mol) of magnesium powder into a 1000ml four-necked flask equipped with a thermometer, reflux condensing device, drying device, dropping device, and stirring device, and at the same time add 100ml of ether solvent anhydrous ether to immerse the magnesium powder, and heat After reaching 35°C, add 0.5g initiator iodine to initiate the reaction and produce a violent reflux. After the reflux is stable, add dropwise a mixed liquid of 92.5g (1mol) chlorobutane and 400ml ether solvent diethyl ether, and keep the reflux during the dropping process. The dropwise addition time is 50 minutes, after the dropwise addition is completed, keep refluxing for 5 hours, and the resulting reaction solution is Grignard reagent tert-butylmagnesium chloride;

[0033] ② Cool the reaction liquid Grignard reagent tert-butylmagnesium chloride prepared in step ① to 20°C, feed ethylene oxide ga...

Embodiment 3

[0038] Prepare 3, the concrete preparation steps of 3-dimethyl-1-butanol are as follows:

[0039] ①In a 1000ml four-neck flask equipped with a thermometer, reflux condensing device, drying device, dropping device, and stirring device, add 27.6g (1.15mol) of magnesium powder, and at the same time add 100ml of ether solvent tetrahydrofuran to immerse the magnesium powder, and heat to 45 After ℃, add 0.5g initiator iodine to initiate the reaction and produce violent reflux. After the reflux is stable, add dropwise the mixed liquid of 137g (1mol) bromo-tert-butane and 400ml ether solvent tetrahydrofuran. For 45 minutes, after the dropwise addition was completed, it was kept under reflux for 3.5 hours, and the resulting reaction solution was Grignard reagent tert-butylmagnesium bromide;

[0040] ② Cool the reaction liquid Grignard reagent tert-butylmagnesium bromide prepared in step ① to 10°C, feed ethylene oxide gas and control the ventilation speed to keep the temperature of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com