Method of recycling molybdenum and rhenium from molybdenum concentrate by hydrometallurgy

A technology for hydrometallurgy and molybdenum concentrate, which is applied in the direction of improving process efficiency to achieve the effects of improving pH value, excellent separation effect and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

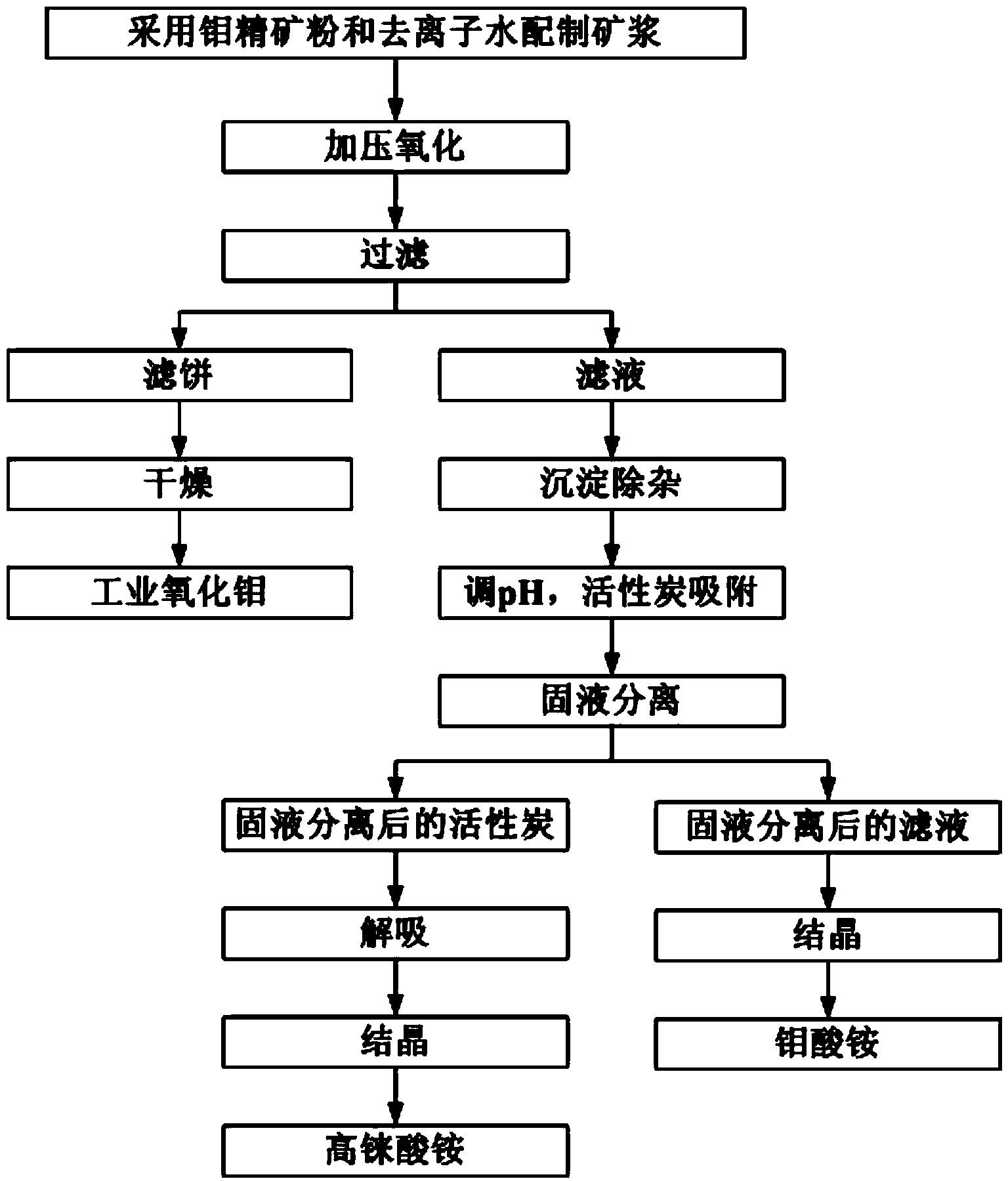

[0041] In the molybdenum concentrate to be processed in this embodiment, the mass percentage of molybdenum is 55%, and the mass percentage of rhenium is 0.04%. Combine figure 1 In this embodiment, the method of hydrometallurgical recovery of molybdenum and rhenium from molybdenum concentrate includes the following steps:

[0042] Step 1: Mix molybdenum concentrate and deionized water evenly according to a solid-liquid ratio of 1:10 to obtain a slurry;

[0043] Step 2. Under an oxygen atmosphere, use a high-pressure reactor to perform pressure oxidation treatment on the pulp described in Step 1. The temperature of the pressure oxidation treatment is 180°C, and the time of the pressure oxidation treatment is 2 hours. The pressure of the pressure oxidation treatment is 0.6MPa; after the pressure oxidation treatment, the molybdenum concentrate is mainly oxidized into molybdenum trioxide and transferred to the solid phase, and part of the molybdenum exists in the form of molybdate and ...

Embodiment 2

[0057] In the molybdenum concentrate to be processed in this embodiment, the mass percentage of molybdenum is 45%, and the mass percentage of rhenium is 0.02%. Combine figure 1 In this embodiment, the method of hydrometallurgical recovery of molybdenum and rhenium from molybdenum concentrate includes the following steps:

[0058] Step 1: Mix molybdenum concentrate and deionized water evenly according to a solid-liquid ratio of 1:10 to obtain a slurry;

[0059] Step 2. Under an oxygen atmosphere, use an autoclave to perform pressure oxidation treatment on the pulp described in step 1, the temperature of the pressure oxidation treatment is 200°C, and the time of the pressure oxidation treatment is 1.5h, so The pressure of the pressure oxidation treatment is 0.7 MPa; after the pressure oxidation treatment, the molybdenum concentrate is mainly oxidized into molybdenum trioxide and transferred into the solid phase, and part of the molybdenum exists in the form of molybdate and transfer...

Embodiment 3

[0073] In the molybdenum concentrate to be processed in this embodiment, the mass percentage of molybdenum is 57%, and the mass percentage of rhenium is 0.04%. Combine figure 1 In this embodiment, the method of hydrometallurgical recovery of molybdenum and rhenium from molybdenum concentrate includes the following steps:

[0074] Step 1. Mix the molybdenum concentrate and deionized water evenly according to the solid-liquid ratio of 1:12 to obtain a slurry;

[0075] Step 2. Under an oxygen atmosphere, use a high-pressure reactor to perform pressure oxidation treatment on the pulp described in Step 1. The temperature of the pressure oxidation treatment is 180°C, and the time of the pressure oxidation treatment is 2 hours. The pressure of the pressure oxidation treatment is 0.5MPa; after the pressure oxidation treatment, the molybdenum concentrate is mainly oxidized into molybdenum trioxide and transferred to the solid phase, and part of the molybdenum exists in the form of molybdat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com