ReS2/CdS photocatalyst and preparation method and application thereof

A photocatalyst and photocatalytic technology, applied in the field of photocatalysis, can solve the problems of cost limitation and high scarcity of Pt, and achieve the effects of good stability, simple preparation method and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

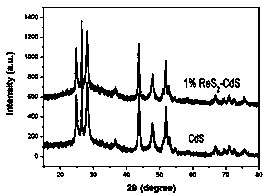

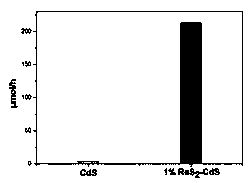

Image

Examples

Embodiment 1

[0034] A ReS 2 The preparation method of / CdS photocatalyst comprises the following steps:

[0035] (1) Dissolve 4.317 g of chromium acetate dihydrate in 30 mL of ethylenediamine, weigh 3.699 g of thiourea and dissolve in 30 mL of ethylenediamine, and slowly drop the latter into the former to obtain mixed solution A;

[0036] (2) Put the mixed solution A obtained in step (1) into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 24 h;

[0037] (3) After the reaction is completed, wait for the hydrothermal reaction kettle to cool down to room temperature, then wash the yellow product cadmium sulfide in the hydrothermal reaction kettle with ethanol and deionized water three times respectively, dry and set aside;

[0038] (4) Weigh 400 mg of cadmium sulfide semiconductor material obtained in step (3), 10.02 mg of ammonium perrhenate, and 5.617 mg of thioacetamide, dissolve ammonium perrhenate and thioacetamide in 40 ml of distilled water, and stir f...

Embodiment 2

[0042] A ReS 2 The preparation method of / CdS photocatalyst comprises the following steps:

[0043] (1) Dissolve 4.317 g of chromium acetate dihydrate in 30 mL of ethylenediamine, weigh 3.699 g of thiourea and dissolve in 30 mL of ethylenediamine, and slowly drop the latter into the former to obtain mixed solution A;

[0044](2) Put the mixed solution A obtained in step (1) into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160 °C for 20 h;

[0045] (3) After the reaction is completed, wait for the hydrothermal reaction kettle to cool down to room temperature, then wash the yellow product cadmium sulfide in the hydrothermal reaction kettle with ethanol and deionized water three times respectively, dry and set aside;

[0046] (4) Weigh 400 mg of cadmium sulfide semiconductor material obtained in step (3), 1.002 mg of ammonium perrhenate, and 0.561 mg of thioacetamide, dissolve ammonium perrhenate and thioacetamide in 40 ml of distilled water, and stir f...

Embodiment 3

[0050] A ReS 2 The preparation method of / CdS photocatalyst comprises the following steps:

[0051] (1) Dissolve 4.317 g of chromium acetate dihydrate in 30 mL of ethylenediamine, weigh 3.699 g of thiourea and dissolve in 30 mL of ethylenediamine, and slowly drop the latter into the former to obtain mixed solution A;

[0052] (2) Put the mixed solution A obtained in step (1) into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 150 °C for 24 h;

[0053] (3) After the reaction is completed, wait for the hydrothermal reaction kettle to cool down to room temperature, then wash the yellow product cadmium sulfide in the hydrothermal reaction kettle with ethanol and deionized water three times respectively, dry and set aside;

[0054] (4) Weigh 400 mg of cadmium sulfide semiconductor material obtained in step (3), 5.01 mg of ammonium perrhenate, and 2.81 mg of thioacetamide, dissolve ammonium perrhenate and thioacetamide in 40 ml of distilled water, and stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com