Method for producing temperature measuring tungsten-rhenium thermocouple wires in high-reliability manner through combined technology

A technology of thermocouple wire and reliability, which is applied in the field of powder metallurgy manufacturing, can solve the problems of large difference in thermoelectric potential between the head and the tail of the couple wire, difficult to press and sinter, and cannot be completely replaced, so as to improve the level of process control, uniform composition, and improve consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0024] A method for producing tungsten-rhenium thermocouple wire for temperature measurement with high reliability by using combined technology

[0025] This embodiment takes WRe5.45 tungsten-rhenium thermocouple wire as an example to illustrate

[0026] (1) Preparation method:

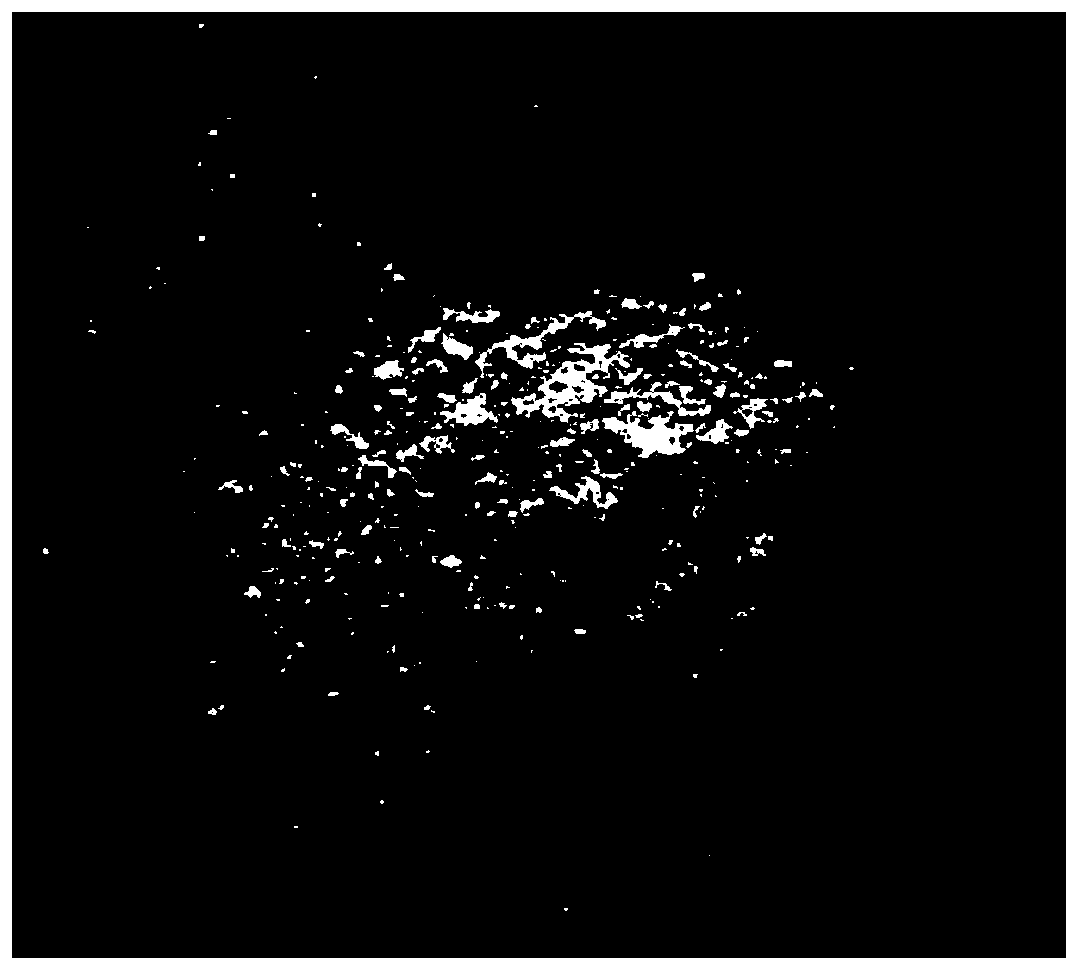

[0027] 1) Preparation of tungsten-rhenium alloy compound powder by full liquid phase mixing method: 1 kg of commercially available ammonium tungstate with a purity of 4N (99.99%) was dissolved in water, and 0.058 kg of commercially available ammonium tungstate with a purity of 4N (99.99%) was dissolved in water. Dissolve ammonium rhenate in water, stir ammonium tungstate aqueous solution and ammonium perrhenate aqueous solution at 85°C, and then use spray crystallization method to make such figure 1 Tungsten-rhenium alloy compound powder shown.

[0028] 2) Tablet preparation to obtain debris: place the tungsten-rhenium alloy compound powder obtained in step 1) at a unit pressure of 60kg / cm 2 The st...

Embodiment 2

[0041]A method for producing tungsten-rhenium thermocouple wire for temperature measurement with high reliability by using combined technology

[0042] This embodiment takes WRe5.45 tungsten-rhenium thermocouple wire as an example for illustration

[0043] (1) Preparation method:

[0044] 1) Preparation of tungsten-rhenium alloy compound powder by full liquid phase mixing method: 1 kg of commercially available ammonium tungstate with a purity of 4N (99.99%) was dissolved in water, and 0.058 kg of commercially available ammonium tungstate with a purity of 4N (99.99%) was dissolved in water. Dissolve ammonium rhenate in water, stir ammonium tungstate aqueous solution and ammonium perrhenate aqueous solution at 95°C, and use spray crystallization method to make such figure 1 Tungsten-rhenium alloy compound powder shown.

[0045] 2) Tablet preparation to obtain debris: place the tungsten-rhenium alloy compound powder obtained in step 1) at a unit pressure of 150kg / cm 2 The stan...

Embodiment 3

[0058] A method for producing tungsten-rhenium thermocouple wire for temperature measurement with high reliability by using combined technology

[0059] This embodiment takes WRe5.45 tungsten-rhenium thermocouple wire as an example for illustration

[0060] (1) Preparation method:

[0061] One) preparation method:

[0062] 1) Preparation of tungsten-rhenium alloy compound powder by full liquid phase mixing method: 1 kg of commercially available ammonium tungstate with a purity of 4N (99.99%) was dissolved in water, and 0.058 kg of commercially available ammonium tungstate with a purity of 4N (99.99%) was dissolved in water. Dissolve ammonium rhenate in water, stir ammonium tungstate aqueous solution and ammonium perrhenate aqueous solution at 100°C, and then use spray crystallization method to make such figure 1 Tungsten-rhenium alloy compound powder shown.

[0063] 2) Tablet preparation to obtain debris: place the tungsten-rhenium alloy compound powder obtained in step 1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com