A method for recovering rhenium and other metals from rhenium-bearing materials

A technology for platinum group metals and metal salt solutions, which can be used in chemical instruments and methods, rhenium compounds, and the improvement of process efficiency, and can solve problems such as shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

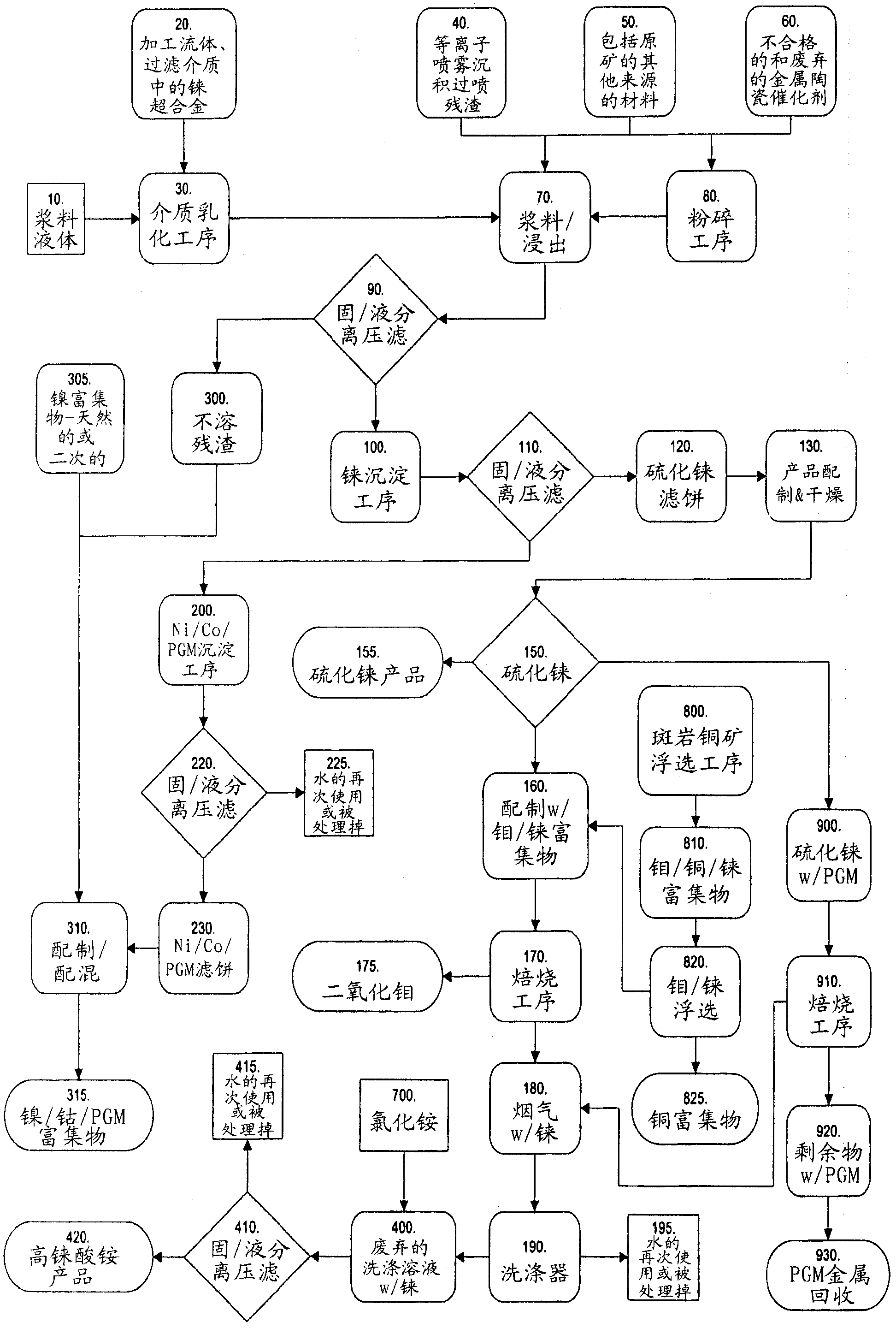

[0017] A variety of Re-containing materials can be treated in accordance with the present invention. For example, the figures show that these materials may include Re-containing superalloy residues and waste 20, Re-containing plasma spray deposited overspray residues 40, materials from other sources such as Re-containing ore materials 50, and / or Re-containing waste and cermet catalysts 60 .

[0018] When the Re-containing material is from a superalloy waste or residue material 20 such as machining fluid or filter media, the superalloy waste or residue material 20 is first mixed with a slurry 10 such as an aqueous solution. The aqueous solution and superalloy waste or residue material 20 are thoroughly agitated or subjected to a media emulsification process 30 to form a Re-containing mixture. The Re-containing mixture is then combined with other Re-containing materials such as Re-containing superalloy residues and waste 20, Re-containing plasma spray deposited overspray residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com