Method for preparing ammonium perrhenate from waste liquid containing molybdenum and rhenium

A technology of ammonium perrhenate and waste liquid, which is applied in the field of separation chemistry, can solve the problems of environmental pollution and high cost of eluent, and achieve the effects of environmental protection, social and environmental benefits, and resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

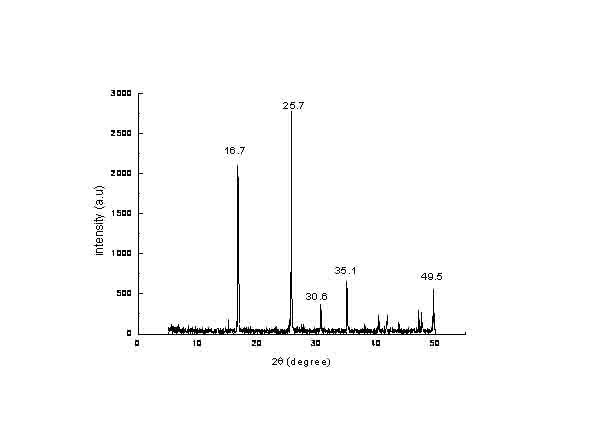

Image

Examples

Embodiment 1

[0017] Embodiment 1 The method for preparing ammonium perrhenate from waste liquid containing molybdenum rhenium

[0018] Raw materials: Molybdenum roasting flue gas absorption liquid provided by a company A: detected by inductively coupled plasma mass spectrometry, the molybdenum roasting flue gas absorption liquid contains 10g / L of molybdenum, 0.8g / L of rhenium, and 12g / L of iron .

[0019] Method: Take molybdenum roasting flue gas absorption liquid, add 6% hydrogen peroxide until the solution turns yellow (add 50 ml of hydrogen peroxide per liter of absorption liquid), add compounding agent (a mixture of calcium hydroxide and calcium oxide in a weight ratio of 5:1) When the pH is 6-7, separate by pressure filtration, and adsorb the filtrate on an ion-exchange resin column (the ion-exchange resin column is a tertiary aminostyrene anion-exchange column), and stop the adsorption when the concentration of rhenium in the effluent remains unchanged. Resin after full load, use NH...

Embodiment 2

[0023] Embodiment 2 The method for preparing ammonium perrhenate from waste liquid containing molybdenum rhenium

[0024] Raw materials: Molybdenum roasting flue gas absorption liquid provided by a company B: detected by inductively coupled plasma mass spectrometry, the molybdenum roasting flue gas absorption liquid contained 15 g / L of molybdenum, 0.4 g / L of rhenium, and 15 g / L of iron. L.

[0025] Method: Take molybdenum roasting flue gas absorption liquid, add 6% hydrogen peroxide until the solution turns yellow (add 78 ml of hydrogen peroxide per liter of absorption liquid), add compounding agent (a mixture of calcium hydroxide and calcium oxide in a weight ratio of 5:1) When the pH is 6-7, press filtration to separate, and adsorb the filtrate on an ion exchange resin column (the ion exchange resin column is a tertiary aminostyrene anion exchange column), and stop the adsorption when the concentration of rhenium in the effluent remains unchanged. Resin after full load, use...

Embodiment 3

[0029] Embodiment 3 The method for preparing ammonium perrhenate from waste liquid containing molybdenum rhenium

[0030] Raw materials: Molybdenum roasting flue gas absorption liquid provided by a company C: It is detected by inductively coupled plasma mass spectrometry, and the molybdenum roasting flue gas absorption liquid contains 0.5g / L of molybdenum, 1.0g / L of rhenium, and 3g / L of iron. L.

[0031]Method: Take molybdenum roasting flue gas absorption liquid, add 6% hydrogen peroxide until the solution turns yellow (add 5 ml hydrogen peroxide per liter of absorption liquid), add compounding agent (a mixture of calcium hydroxide and calcium oxide in a weight ratio of 5:1) When the pH is 6-7, separate by pressure filtration, and adsorb the filtrate on an ion-exchange resin column (the ion-exchange resin column is a tertiary aminostyrene anion-exchange column), and stop the adsorption when the concentration of rhenium in the effluent remains unchanged. Resin after full load,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com