Method for preparing ammonium perrhenate

A technology of ammonium perrhenate and ammonium salt, applied in the direction of improving process efficiency, can solve problems such as affecting industrial utilization, low product quality, waste of resources, etc., and achieve high quality, comprehensive recovery and utilization, and widely available raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

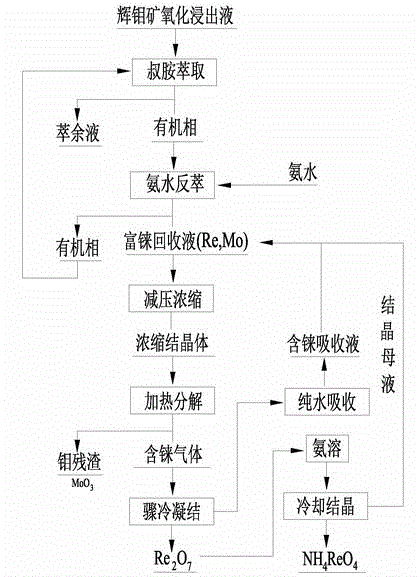

[0048] Ammonium perrhenate is prepared by using molybdenite oxidation leaching solution as raw material, enriched by solvent extraction, concentrated under reduced pressure, thermally decomposed and dissolved and crystallized. The preparation process is as follows figure 1 shown.

[0049] Rhenium-depleted stock solution: molybdenite oxidation leaching solution, which is obtained by high pressure oxygen leaching of molybdenite. The composition of the leaching solution is 0.116 g / L and Mo is 23.4 g / L. In industrial practice, since rhenium is a kind of scattered metal, its content in the earth's crust is about 1×10ˉ 7 %, it is very rare in nature, and its content is low in rhenium-containing ores. The content of rhenium in the poor rhenium stock solution produced after pyrolysis or wet decomposition is low, and the rhenium-containing liquid with rhenium content less than 0.01g / L is equivalent to Each ton of the solution contains less than 10 grams of rhenium, which is of li...

Embodiment 2

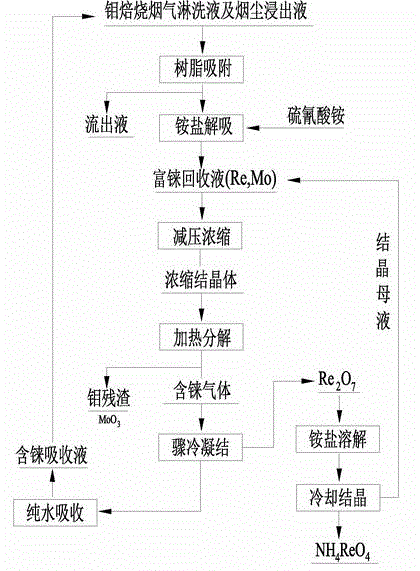

[0074] The rhenium compound ammonium perrhenate is prepared by using molybdenite roasting flue gas eluate and smoke leaching liquid as raw materials, ion exchange resin adsorption enrichment, vacuum concentration, thermal decomposition and dissolution crystallization. The preparation process is as follows image 3 shown.

[0075] Rhenium-depleted stock solution: molybdenite roasting flue gas eluate and soot leaching liquid, the molybdenite roasting temperature is 600°C, the roasting method is fluidized roasting, and the rhenium content in the molybdenite roasting flue gas eluent is 1.4g / L, the molybdenum content is 16g / L.

[0076] Prepare ammonium perrhenate, concrete steps are as follows:

[0077] Step 1: Concentrate under reduced pressure to prepare concentrated crystals

[0078] This example uses ion exchange resin adsorption and ammonium salt desorption to collect NH 4 ReO 4 The rhenium-rich recovery solution is concentrated under reduced pressure at 95°C to obtain co...

Embodiment 3

[0101] In this embodiment, the molybdenite electro-oxidizing solution is used as raw material, and the rhenium compound ammonium perrhenate is prepared by extracting and enriching with an organic solvent, concentrating under reduced pressure, thermally decomposing, and dissolving and crystallizing.

[0102] Rhenium-depleted stock solution: molybdenite electrooxidation solution. The molybdenum concentrate slurry made by mixing molybdenum concentrate with 10% NaCl is electrolyzed. During the solution electrolysis, the anode generates oxidant ClO - , the molybdenum concentrate particles are oxidized by the electrochemical oxidant and dissolved in the solution, the composition of the electro-oxidant solution: rhenium 0.038g / L, molybdenum 15 g / L.

[0103] Prepare ammonium perrhenate, concrete steps are as follows:

[0104] Step 1: Concentrate under reduced pressure to prepare concentrated crystals

[0105] In this example, quaternary ammonium salt extraction and perchloric acid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com